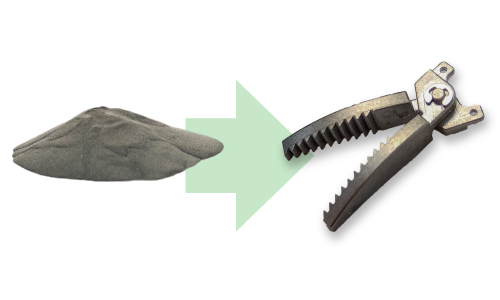

m:MIM (micro MIM) NEW

V-LINE®'s precise control and high responsiveness help reduce man-hours for precision MIM parts

* The picture shown may slightly differ from the actual machine.

Main Features

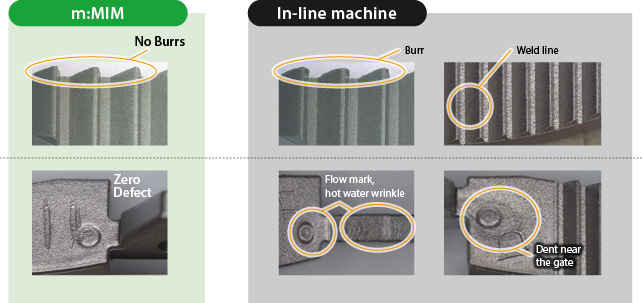

- Maximizes V-LINE® injection performance

- By separating the plasticizing and injection sections, V-LINE® realizes stable melt conditions and accurate filling volume in metal powder injection moulding. Even under rapid deceleration conditions to suppress burrs, the amount of filling is accurately controlled, and no shape change or distortion of the external appearance occurs. V-LINE® maximizes injection performance in MIM moulding as well.

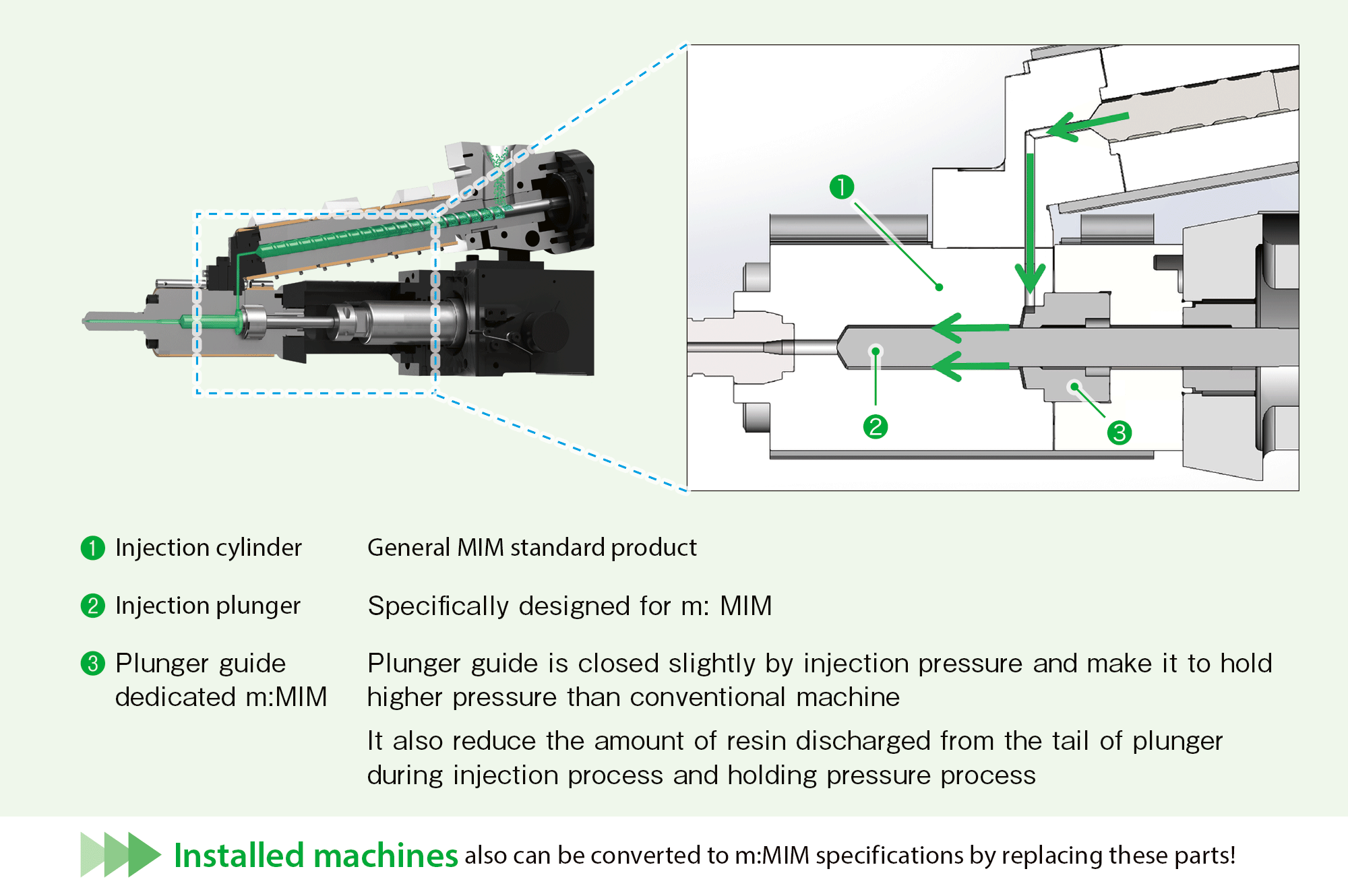

- New "m:MIM-specific" injection structure

- Highly lubricated steel is used for the injection sliding parts, making the structure less susceptible to damage by metal powder. The machine is capable of moulding with high injection holding pressure, and temperature control at the rear of the injection plunger improves the stability of injection operation while reducing the amount of discharged material to realize net-shape moulding, which requires no secondary processing.

- Rich product line

-

eV-LINE® Electric model MS50G2

V-LINE® Electric Hybrid Model GL30

V-LINE® Electric Hybrid Model GL60

※"m:MIM" can be retrofitted to machines that have already been installed. Also, the specifications differ slightly from those of regular machines. Please contact us for more details.

Movie

Products

| Moulding application | Metal Powder Injection Moulding |

|---|