Sodick Z Wire (e80 Wire)

Effective in rough machining

Machining finish of approx. 5μm

Features

- Improved machining speed

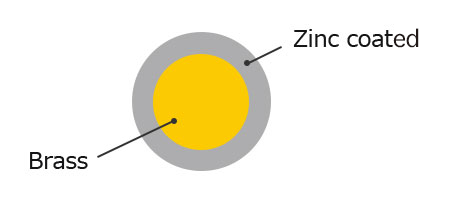

- Zinc coating gives high electrical discharge efficiency and boosts machining speeds by 10-50% as compared with brass wire.

- Non adhesion of brass

- There is no adhesion of brass to the machined surface that occurs by the brass electrode wire.

- Less Breakage

- A high electrical discharge limit as compared with brass wire electrodes reduces wire breakage during machining.

- Exellent perfomance on various materials.

- Exellent performance in difficult materials such as carbide, titanium, inconel, etc.

- Excellent straightness

- Rigorous inspection ensures outstanding straightness and automatic wire threading performance.

Specifications

※You can see the entire Directors and Audit & Supervisori Board Membersable by scrolling horizontally.

| Diameter Tolerance (mm) | +0, -0.002 |

|---|---|

| Tensile (N/mm2) | > 900 |

| Elongation (%) | < 2% |

| Cross section |  |

Product Line-up

※You can see the entire Directors and Audit & Supervisori Board Membersable by scrolling horizontally.

| Order No. | Wire Diameter | Weight | Product name | Spool | Qty / Box | ||

|---|---|---|---|---|---|---|---|

| (φmm) | (in) | (kg) | (lb) | ||||

| 2088341 | 0.20 | 0.008 | 6 | 13.2 | SODICK Z 200 P5-6 | P5 | 4 |

| 2088344 | 8 | 17.6 | SODICK Z 200 D160-8 | D160 | 2 | ||

| 2088502 | 10 | 22.0 | SODICK Z 200 P10-10 | P10 | 1 | ||

| 2087692 | 20 | 44.1 | SODICK Z 200 P20-20 | P20 | 1 | ||

| 2088342 | 0.25 | 0.010 | 6 | 13.2 | SODICK Z 250 P5-6 | P5 | 4 |

| 2088345 | 8 | 17.6 | SODICK Z 250 D160-8 | D160 | 2 | ||

| 2088503 | 10 | 22.0 | SODICK Z 250 P10-10 | P10 | 1 | ||

| 2087694 | 20 | 44.1 | SODICK Z 250 P20-20 | P20 | 1 | ||

| 2088343 | 0.30 | 0.012 | 6 | 13.2 | SODICK Z 300 P5-6 | P5 | 4 |

| 2088346 | 8 | 17.6 | SODICK Z 300 D160-8 | D160 | 2 | ||

| 2088504 | 10 | 22.0 | SODICK Z 300 P10-10 | P10 | 1 | ||

| 2087685 | 20 | 44.1 | SODICK Z 300 P20-20 | P20 | 1 | ||

- Please order by box.

[Caution]

- The surface quality is inferior to brass wire. Surface roughness guideline of 5μm.

- As the surface of the wire is close to the plating, thorough cleaning of the wire guide and surrounding parts is the key to stable performance.

- Powder of the wire suface may generate, therefore periodical cleaning around the guide is recommended.

Contact your nearest Sodick for other sizes.

Please use this form to contact us for any inquiries.