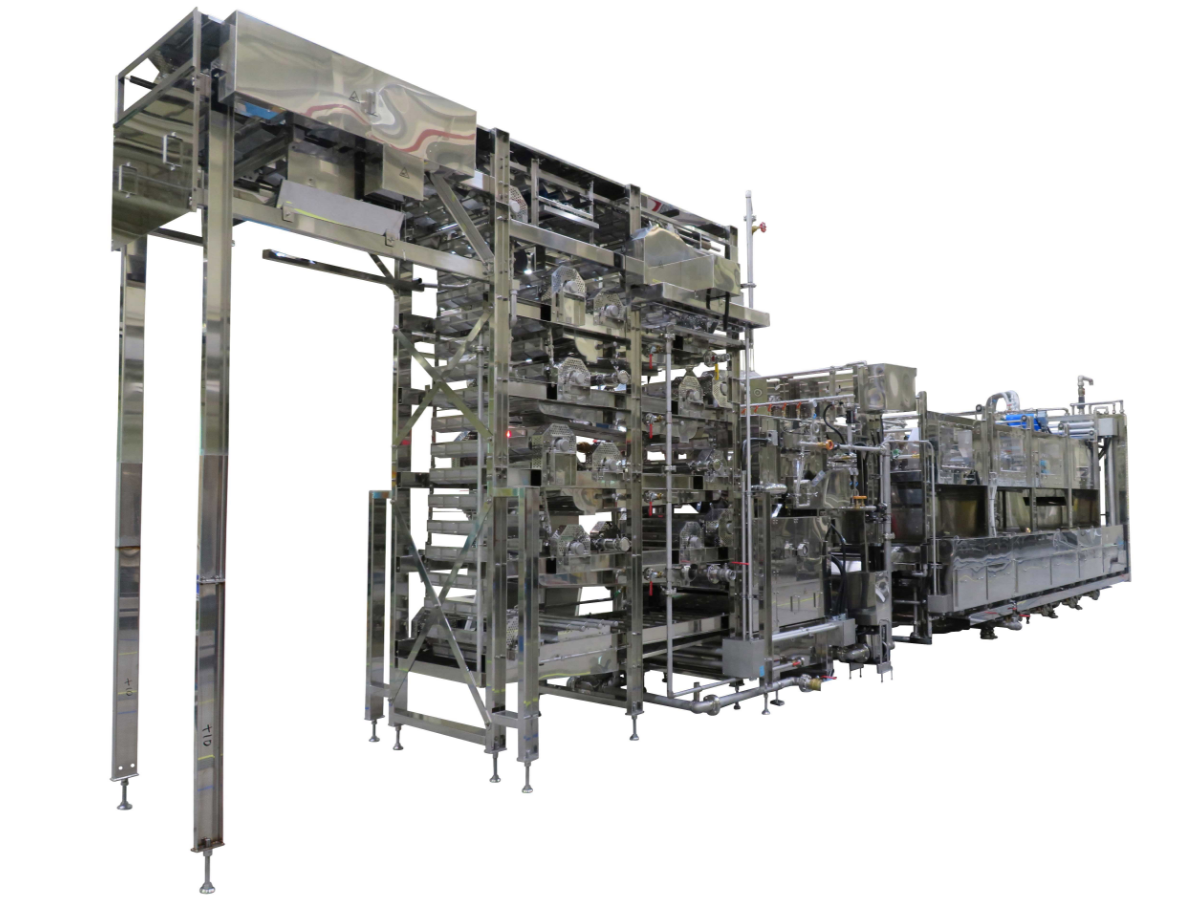

Automatic Boiling Machine with Reversing Baskets

Boils all kinds of noodles, including udon, Chinese noodles, Japanese soba, soumen, and pasta.

Main Features

- (1)Loading conveyor

- The sliding-type loading conveyor automatically loads the noodles. (Dry noodles and pasta)

A door at the entrance stops steam from escaping. - (2)Boiling and inversion unit

- Air-cylinder-driven inversion mechanism.

Offers quiet operation and allows individual time adjustment for each basket.

Powerful pump raveling piping produces uniform noodle boiling.

When the basket inverts, the transfer shower will wash down to remove noodles from the basket.

Hygienic indirect steam heating.

Full upper hood prevents steam escaping around the machine. - (3)Washing and cooling unit

- Uniform cooling achieved by air raveling piping.

Built-in live steam pipes for boiling washing ensure hygienic operation.

The fully stainless-steel construction is durable and extremely hygienic.

Product Specifications

| Model | HAN-43-6-7 |

|---|---|

| Hourly production | 180kg~200kg |

| Boiling tank | 900mm Width x 4 tanks Boiling time: 6 to 22 minutes Pump raveling, air raveling, steam raveling |

| Washing tank | 900mm Width x 4 tanks Washing time 3 minutes With air raveling piping, boiling washing pipes |

| Loading conveyor | Sliding-type automatic loading conveyor |

| Electrical control | Programmed electrical control by sequence |

| Electrical capacity | AC200V 3-phase 6.0kw |

| Options | Salt water delivery system for automatic salt concentration control |

- Other machines can be manufactured with different performance specifications.