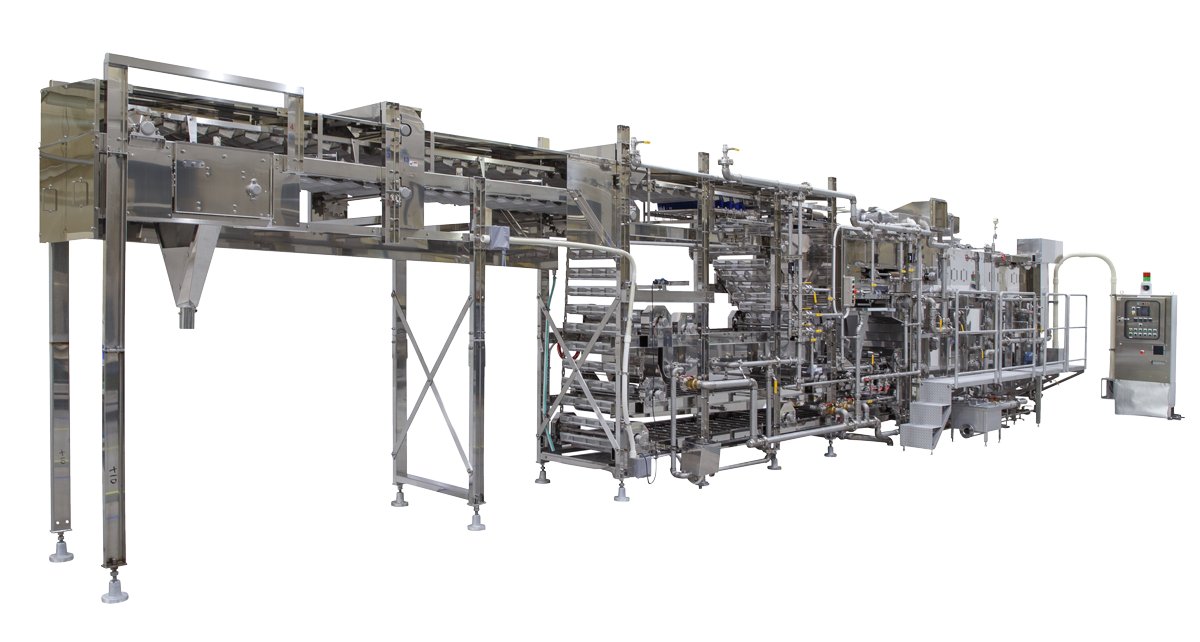

Automatic Noodle Boiling Machine

This is highly efficient noodle boiling equipment that automatically controls the temperature and volume of boiling water to maintain a consistent boil.

CIP fully automatic noodle boiling machine with automatic washing function can be selected.

Main Features

Main Features of the Boiling Tank

- Featured with Cooker’s Bottom Heating system for shorter heating time and improved washability.

- Safety system

- Overload protection devises for safety are equipped with at various places.

- Boiling temperature and boiling time control

- The hot water temperature and boiling time are controlled with a digital thermometer and digital timer.

- Up to 4 raw noodle outlet ports are possible

- Proportional control of hot water temperature

- The water temperature is detected at all times, and the steam proportional control valve is automatically opened and closed.

Main features of the cooling tank

- High-efficiency cooling

- Boiled noodles are efficiently cooled by a 3-step counterflow cooling tank.

Product Specifications

| Type | Main Features |

|---|---|

| Single-step external return type | It can be designed according to a variety of boiling time and available space. |

| Two-step center return type | |

| Three-step external return type | |

| Four-step center return type | |

| Five-step external return type | |

| Six-step center return type | |

| Transfer type (Boiling time and performance adjustable) |

By adjusting the effective number of baskets, noodles with different boiling times can be produced with the same production capacity. |

| System for both thick and thin noodles | Providing multiple dispensing drop ports for raw noodles allows both buckwheat noodles/Chinese noodles that have a short boiling time and Udon noodles, which have a long boiling time, to be handled on the same production line. |

| Large double drive system | Complex structural machine design with long bucket chains is made possible by use of two driving systems for bucket chains. |