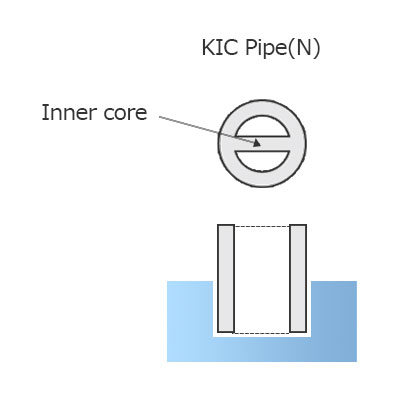

KIC Pipe(N)

High quality, High Precision coreless pipe for small hole EDM

KIC pipe is an electrode designed to prevent the formation of a core in a workpiece by creating a core in the electrode and rotating it while flowing liquid.

Features

- Realization of coreless machining by KIC Pipe

- Coreless machining can be achieved by making a core inside the electrode. Fluid is flown inside while the electrode is rotating, which enables deep hole machining without leaving the core in the workpiece. Not only through hole processing can be made but also bottomed machining is possible.

- KIC pipe electrode is made of 99.9% Copper

- After conducting machining tests on various materials, Cu (99.9%) was chosen as the electrode material for the KIC pipe as it was the most stable material to process. Most commonly used. Pipes and coreless types are available, economical and suitable for deep and continuous machining.

- For machining focused on speed

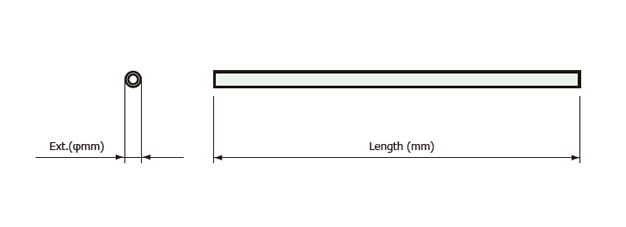

- No variations in diameter and length with excellent straightness. Excellent conductivity and suitable for machining that requires speed.

Specifications

※You can see the entire Directors and Audit & Supervisori Board Membersable by scrolling horizontally.

| Size(mm) | Outer Diameter size(mm) D0.3-3.0 |

|---|---|

| Length(mm) | 300, 400 |

| Cross section |  |

| Appearance |  |

Contact your nearest Sodick for other sizes.

Please use this form to contact us for any inquiries.