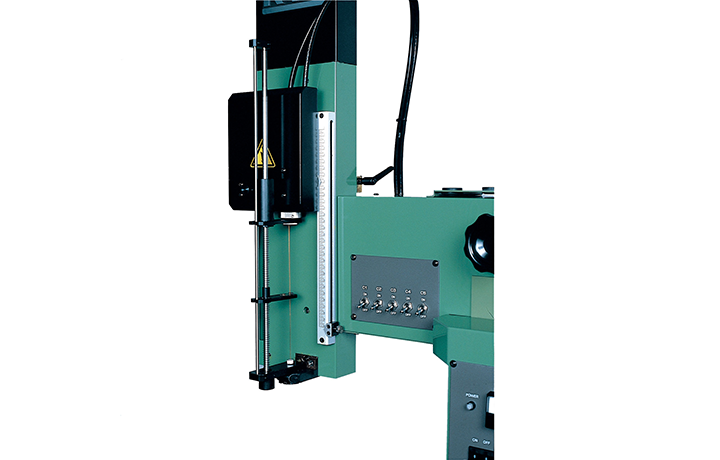

Intermediate Guide Set

Reduces variation in inner diameter accuracy!

Attachments to prevent run-out of electrodes during processing in pipes up to 0.5 sizes.

Features

- Minimizes electrode runout and supports stable machining

- Electrodes of D0.5 or less which has weak rigidity, the electrodes may vibrate due to various factors such as processing conditions, material of the workpiece, and processing depth.

In such cases, the use of an intermediate guide minimizes electrode runout and ensures stable machining.

Specifications

Table of intermediate guide sets by machine model

※You can see the entire Directors and Audit & Supervisori Board Membersable by scrolling horizontally.

| Order No. | Model | Version | Serial No. | Guide assembly type |

Intermediate guide name |

|---|---|---|---|---|---|

| 3560398 | K1C | K1C-1 K1C-2 | #1001-#1340 | A | Intermediate Guide K1C-1 (Drill Chuck Type) |

| #1341-#1345 | |||||

| 3560811 | K1CS | K1C-2 | #1346-#1892 | B | Intermediate Guide K1C-2 (Collet Type) |

| 3561782 | K1C-3 | #1893-#2065 | Intermediate Guide K1C-3 (Collet Type) | ||

| 3552580 | K1C-4 | #2066- M101-M417 C101-C230 S101-S419 | C | Intermediate Guide K1C-4 (Collet Type) | |

| 3564540 | K1C-5 | M501-M840 | Intermediate Guide K1C-5 (Collet Type) | ||

| K1C-6 | G001-G335 | ||||

| K1C-7 | G345-G999 | ||||

| 1001-1035 | |||||

| K1C-9 | 1036-1438 | ||||

| K1C-10 | 1439- | ||||

| - | K1CN | K1CN-1 | #1001-#1181 | B | Intermediate Guide K1CN-1/2 |

| K1CN-2 | #1182-#1214 | ||||

| 3556188 | K1CN-3 K1CN-4 K1CN-5 | #1215- | C | Intermediate Guide for K2CN/K3CN | |

| K2CN | #1001-#1010 | B | Intermediate Guide for K2CN/K3CN | ||

| #1011- | C | ||||

| K3CN | #1001-#1012 | B | Intermediate Guide for K2CN/K3CN | ||

| #1013- | C | ||||

| K3HN | M442- | C | Intermediate Guide for K2CN/K3CN | ||

| - | K2PN | #1001-#1004 | B | Please contact us. | |

| K3PN | #1005- | C | Please contact us. |

Contact your nearest Sodick for other sizes.

Please use this form to contact us for any inquiries.