SCADA* System

* The abbreviation for Supervisory Control And Data Acquisition

Main Features

- Supervisory Control And Data Acquisition

- Control

- Data acquisition

The current status of the line is displayed, and a warning is issued when any condition becomes abnormal.

The setting values and warning conditions for each control device can be changed from a computer to maintain appropriate production.

The necessary data (temperature, pressure, flow rate, etc.) can be recorded.

Product Specifications

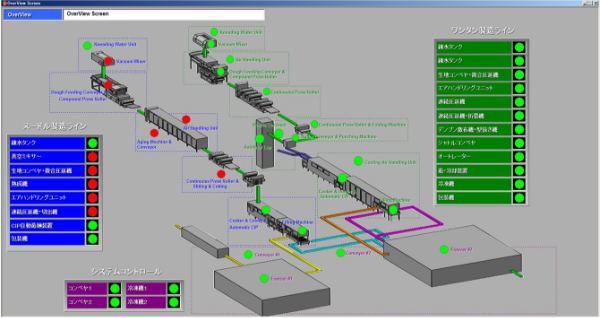

[System Control]

Ascertaining the Production Progress Status

- Implements synchronized control of multiple lines.

- Implements schedule control for production performance / production times.

Ascertains the status of progress of each piece of equipment in multiple lines at any time. - Gives instructions on how to recover when abnormalities occur, and to reduce production losses.

[System Control]

Managing the Schedule (Production Capacity/Time)

- Input the target number of portions to be produced, number of mixing batches, etc.

→ Automatic scheduling and the production processes for one day are displayed. - If multiple lines are being operated, the operation start time for each piece of equipment in the lines is indicated.

→ Losses can be reduced through synchronized timing lags.

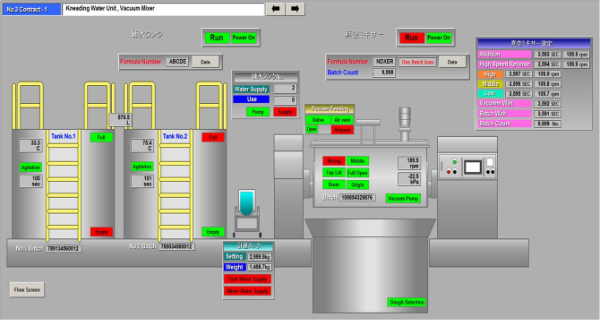

[Monitoring]

Ascertaining the Operation Status of each piece of equipment

- The operation status (motor speeds, time, temperatures, and errors that stop the equipment) is displayed for each piece of equipment.

- Production management information such as batch numbers is displayed.