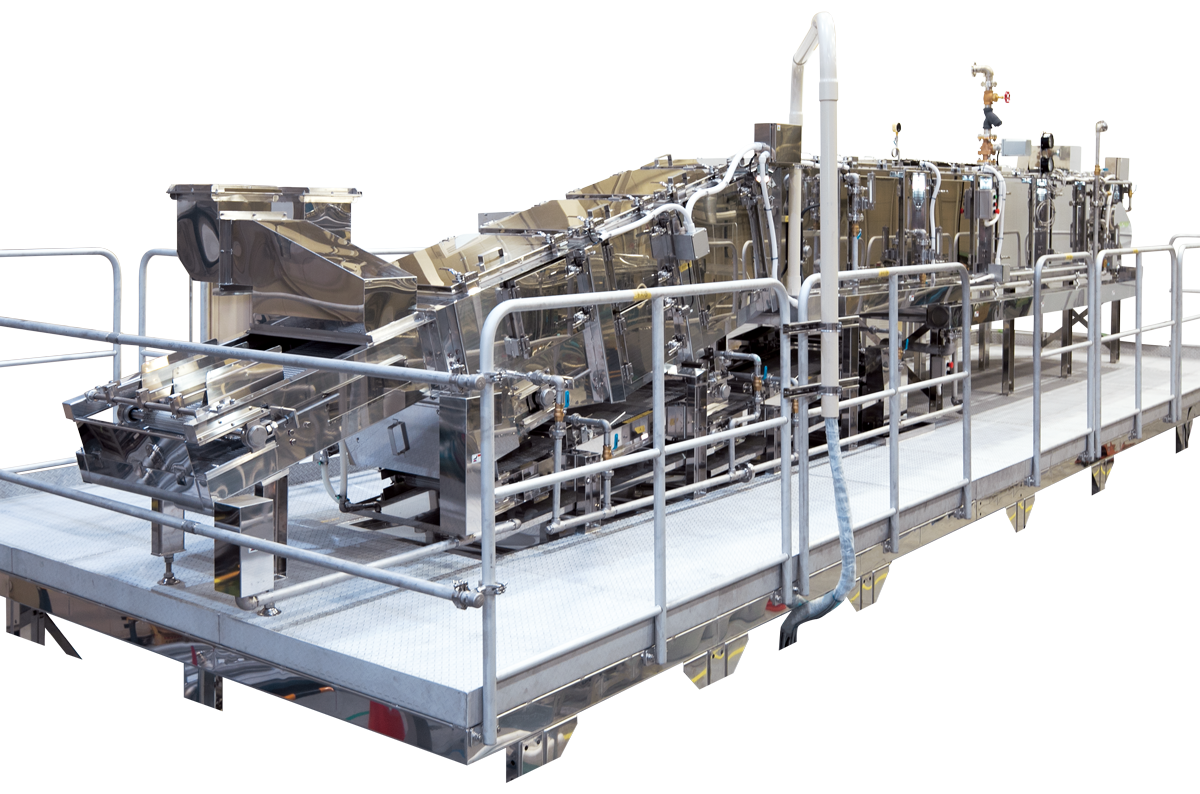

Automatic Noodle Steaming Machine

Steamed Noodles Production Equipment, performing automatically all processes from [steaming] to [washing] and to [water cooling] for Chinese noodles (most typically stir-fried noodles).

Main Features

- Steaming Method

- Straight / Shuttle-type with 2 layer or 3 layer

- Shorter Steaming Time

- By installing a baffle plate inside the steamer for filling the inside with steam, realizing shorter steaming time. In addition, Sodick‘s unique steam injection nozzles are equipped to steam the noodles evenly.

- Improved Maintainability

- Inspection port can be selected from gull-wing type, vertically movable type, and door type. The interior is easy to see, making cleaning and inspection simple.

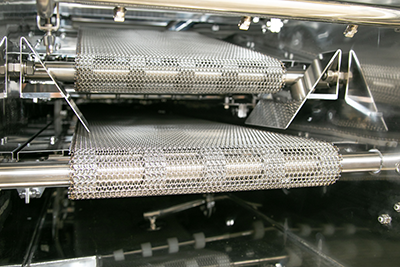

- Chainless net

- The quality of noodle production is stabilized by using chainless nets.

- Stabilization of Noodle Weight

- Encoder-controlled cutting machine cutter is adopted to improve cutting accuracy.

Steam Injection Nozzle

Chainless Net

Noodle-string Slitting and Cutting Machine

Options

- Improved Insulation Effect

- Optional phenolic foam insulation material with double the insulation performance (compared to traditional material like rock wool) helps reduce heat loss. Additionally, along with the structure that prevents steam from leaking, the amount of steam used can be reduced.

Product Specifications

| Model | MO4-6.5-3000 |

|---|---|

| Capacity | 3,000 bags/hour |

| Material | SUS304 |

| Supply steam pressure | 0.2MPa |