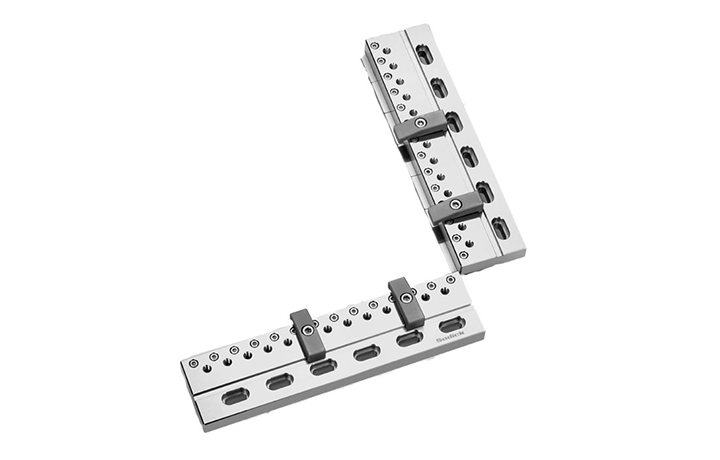

SWS Series Base Plates

General SWS products

Features

- Can be set on either left or right side for you convenience

- SWS base plate can be set either left or right side of the work stand by symmetrcally setting the X and Y bases.

- Can be used individually

- Clamping positions have been remodeled to support large range of machines.

- Two types (L and H) base plates and bridges are available

- Two types (L and H) base plates and bridges are available for machines with different below surface heights.

L-type base plate (standard type)

Upper and lower surface of the base plates can be mounted on the work stand at the same height. As the surface of the work is near the wire guide unit, the jet flush is highly effective, which makes an ideal precision and high speed machining.

H-type base plate (made to order)

Stroke of the machine can be fully used, since the wire guide unit and stopper do not interfere with each other.

H Type cannot be partially removed.

- The size of the workpiece differs depending on the size of the base plate or the machine.

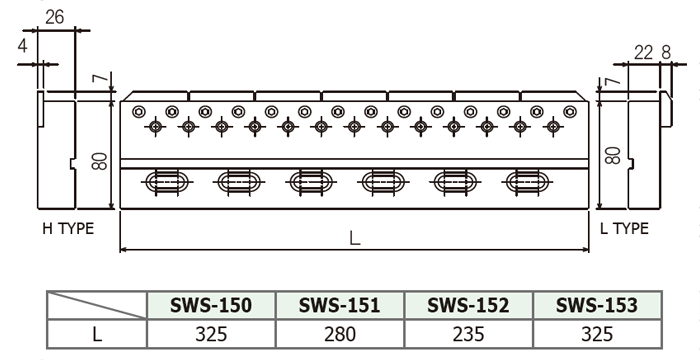

Specifications

Size

※L and H Types are the same length. Max. workpiece weight: 15kg

Attachments

※You can see the entire Directors and Audit & Supervisori Board Membersable by scrolling horizontally.

| Accessories | QTY |

|---|---|

| Pallet Clamp Attachments | 4 pcs |

| Work Clamps | 4 pcs |

| Cap Screw | (quantity will differ according to the model of the machine) |

| Screws(M6 × 25) | 4 pcs |

| Screws(M6 × 18) | 4 pcs |

- Two types (L and H) base plates and bridges are available, allowing the below surface of the work to be set at different heights.

Contact your nearest Sodick for other sizes.

Please use this form to contact us for any inquiries.