LP20EH4 NEW

Ideal for Micro & Precision Small Parts

V-LINE® High Response Injection Moulding Machine for High Value Added Products

* The picture shown may slightly differ from the actual machine.

Main Features

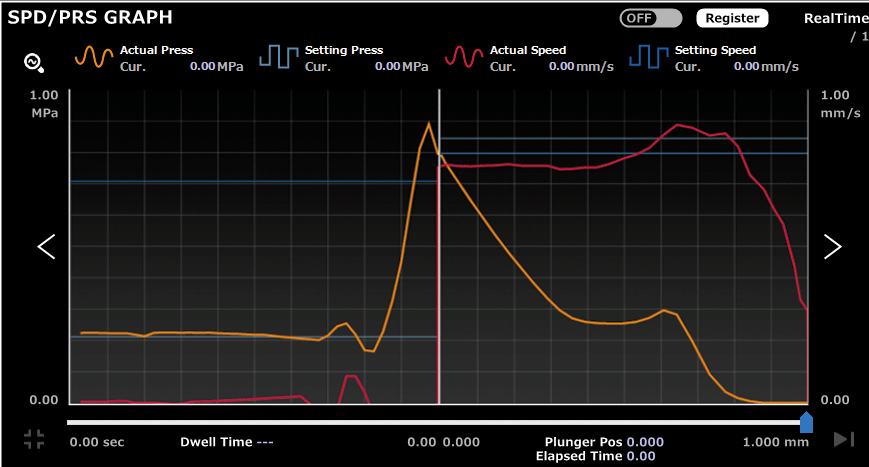

- Industry-Leading Rise and Fall Speeds

- Low-inertia plunger and LDDV achieve industry-leading rise acceleration of 15.3G and a fall time of 5 msec (in the case of P12). The iX controller, developed in-house, also provides optimal and complete control of the injection plunger.

- High-cycle precision stable moulding with V-LINE®

- The V-LINE®'s separate structure for the injection and plastification sections allows for stable plastification, metering, and injection, enabling high-cycle, stable moulding of precision small parts like connectors.

- Operation and management of peripheral equipment with M2M on the operation panel

- In addition to managing the condition of ancillary equipment using M2M, dryers and temperature controllers can also be controlled from the moulding machine's control panel. This contributes to space-saving for our customers' moulding machine peripheral equipment.

Products

| Clamping system | Direct Pressure |

|---|---|

| Max. clamping force (kN) | 196 |

| Tie bar distance W×L (mm) | 310 x 260 |

| Platen Dimensions W×L (mm) | 430 x 360 |

| Open daylight (Min. mould thickness + Max. stroke) (mm) | 400 |

| Min. mould thickness/Max. mould thickness (mm) | 150/ー |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 18 |

| Plunger diameter (mm) | 12 | 16 |

| Max. injection pressure (MPa) | 288 | 262 |

| Theoretical injection volume (cm<sup>3</sup>) | 4.5 | 14 |

| Injection rate (cm<sup>3</sup>/s) | 147 | 161 |

| Max. injection speed (mm/s) | 1300 | 800 |

| Plasticating capacity (kg/h) | 6.5 |

| Machine size L×W×H (mm) | 2632 x 905 x 1760 |

| Machine weight (kg) | 2100 |

| Drive system | Electric Hybrid |