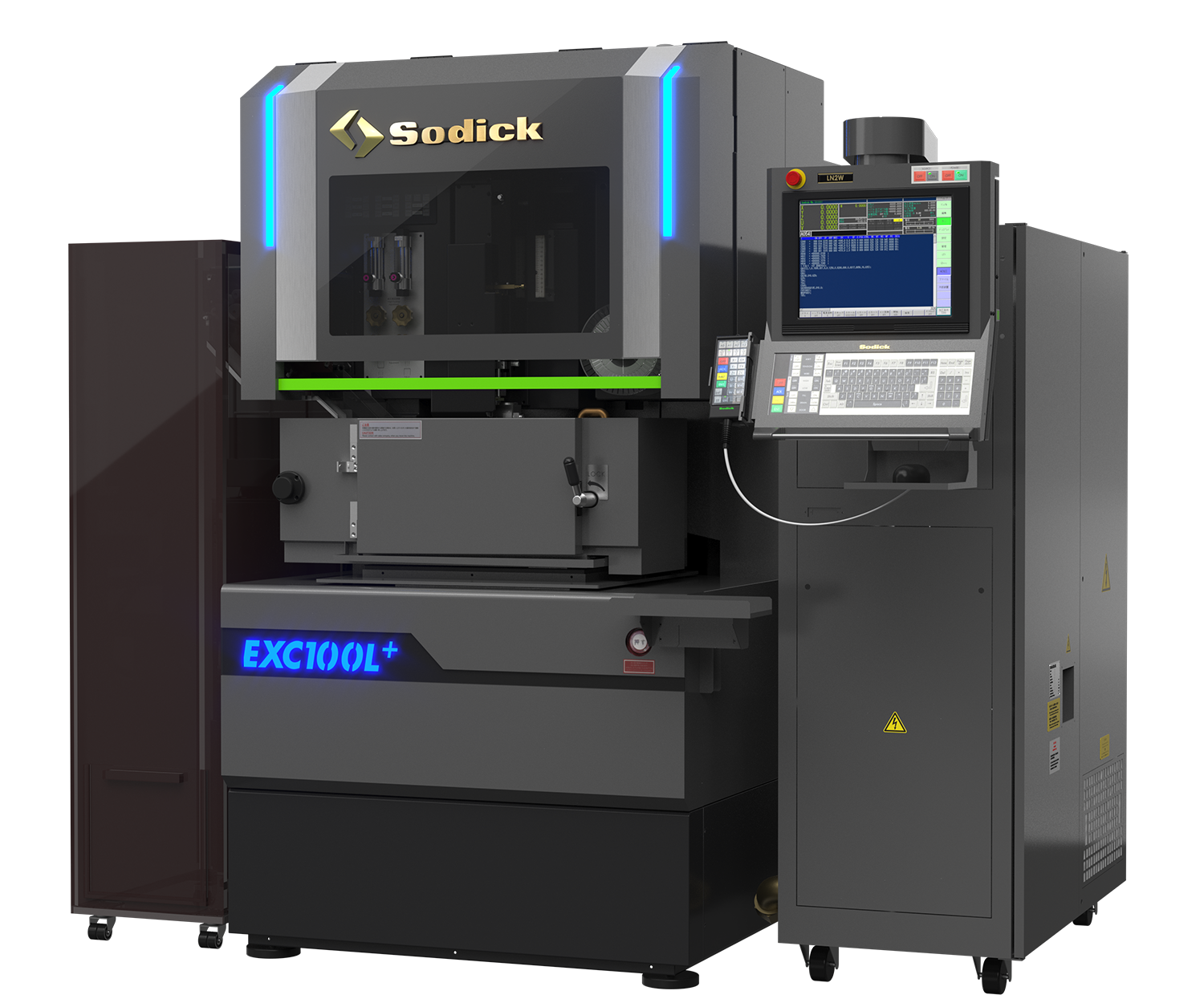

EXC100L+

Screw-less drive and ceramic air slider ultra-precision wire-cut EDM flagship which realizes the ultimate machining

* The picture shown may slightly differ from the actual machine.

Main Features

- Screw-less drive

- The screw-less drive uses a linear motor and a linear scale, realizing excellent positioning accuracy. Because there is no mechanical contact, high response and long term stability and reliability are maintained. By using this drive in combination with a motion controller (SMC) developed by Sodick over many years, maximum performance can be realized.

- LP2W power supply

- In the LP2W power supply, a 3D solid model can be directly imported and used for machining, thus realizing significantly increased machining performance that exceeds the machining know-how of a skilled worker. The ideal machining conditions can be automatically created from a 3D solid model, permitting virtually unmanned operation and a significant reduction of labor.

- Nano-quality machining

- This machine employs the world’s first completely contact-less XY orthogonal table which uses our ceramic air sliders and linear motors. In addition, it incorporates a high resolution linear scale, realizing a minimum drive unit of 10 nanometers (0.01µm). A high performance machining fluid cooling unit is standard fitment, maintaining stable super-precision machining.

Products

| Axis stroke X×Y×Z (mm) | 100 x 120 x 100 |

|---|---|

| U x V axis travel (mm) | 20 x 20 |

| Max. taper angle | ±6°(plate thickness:60mm) |

| Max. workpiece dimensions(During flushing machining) W x D x H (mm) | 150 x 150 x 60 |

| Max. weight of workpiece(During flushing machining)(kg) | 10 *1 |

| Wire electrode diameter (mm) | 0.02 ~ 0.1 |

| Wire tension (N) | 0.5 ~ 10 |

| Maximum wire feed rate (mm/sec) | 250 |

| Distance from floor surface to upper surface of table (mm) | 1050 |

| Machine tool dimensions W x D x H (mm) | 2250 x 2290 x 1990 *2 |

| Machine installation dimensions W x D (mm) | 2850 x 2900 |

| Total unit weight(kg) | 2500 *3 |

| Total power input | 3-phase 50/60Hz 9 kVA |