AL400G "i Groove + Edition" NEW

Newly developed Digital HF control, wire rotation mechanism, energy-saving pump Manufacturing that is both "High-speed" and "Eco-friendly" that can be changed digitally

* The picture shown may slightly differ from the actual machine.

Main Features

- 4-axis Linear Motor Drive

- High-performance linear motors developed and manufactured in-house are used for four axes (XYUV). Precise axis movements without backlash can be maintained semi-permanently. Demonstrates accurate position control and excellent discharge characteristics while machining, through the high response and high following characteristics which are the features of the linear motor.

- Improved Machining Speed

- Newly developed Digital HF control is adopted. By constantly digitally monitoring the status during machining and maintaining optimum discharge conditions, the controller simultaneously improves machining speed and accuracy. By constantly monitoring the discharge state during machining, stable machining can be maintained at all times, even with changes in water quality or plate thickness.

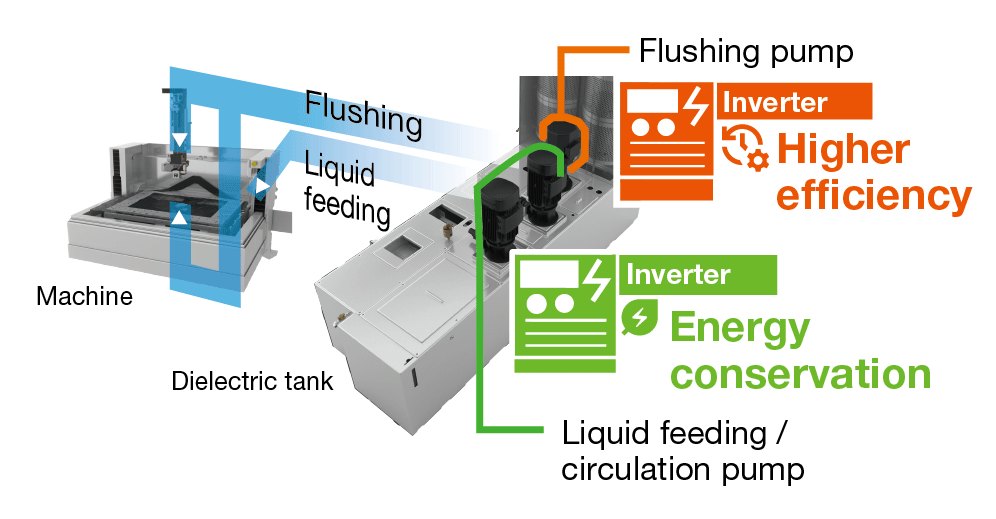

- Eco-friendly

- The wire rotation mechanism (i groove) always performs finish machining with a wear-free wire surface, enabling uniform machining from the top to the bottom of the workpiece. Reduces wire consumption while reducing streaks and irregularities during finishing of thick workpieces. In addition, a newly developed energy-saving pump system has been adopted for the dielectric tank, reducing power consumption.

Products

| Work tank inner dimensions W x D (mm) | 850 x 610 |

|---|---|

| Axis stroke X×Y×Z (mm) | 400 x 300 x 250 |

| U x V axis travel (mm) | 150 x 150 |

| Max. taper angle | ± 25° (Thickness: 130 mm) |

| Max. workpiece dimensions(During flushing machining) W x D x H (mm) | 600 x 470 x 240 |

| Max. workpiece dimensions(During submerged machining) W x D x H (mm) | 600 x 470 x 230 |

| Max. weight of workpiece(During flushing machining)(kg) | 500 |

| Max. weight of workpiece(During submerged machining)(kg) | 350 |

| Wire electrode diameter (mm) | 0.05 ~ 0.3 *1 |

| Wire tension (N) | 3 ~ 23 |

| Maximum wire feed rate (mm/sec) | 420 |

| Distance from floor surface to upper surface of table (mm) | 995 |

| Machine tool dimensions W x D x H (mm) | 2190 x 2590 x 2230 |

| Machine installation dimensions W x D (mm) | 3425 x 3850 |

| Total unit weight(kg) | 3400 |

| Total power input | 3-phase 50/60 Hz Normal Use 9 kVA Maximum Use 13 kVA *2 |