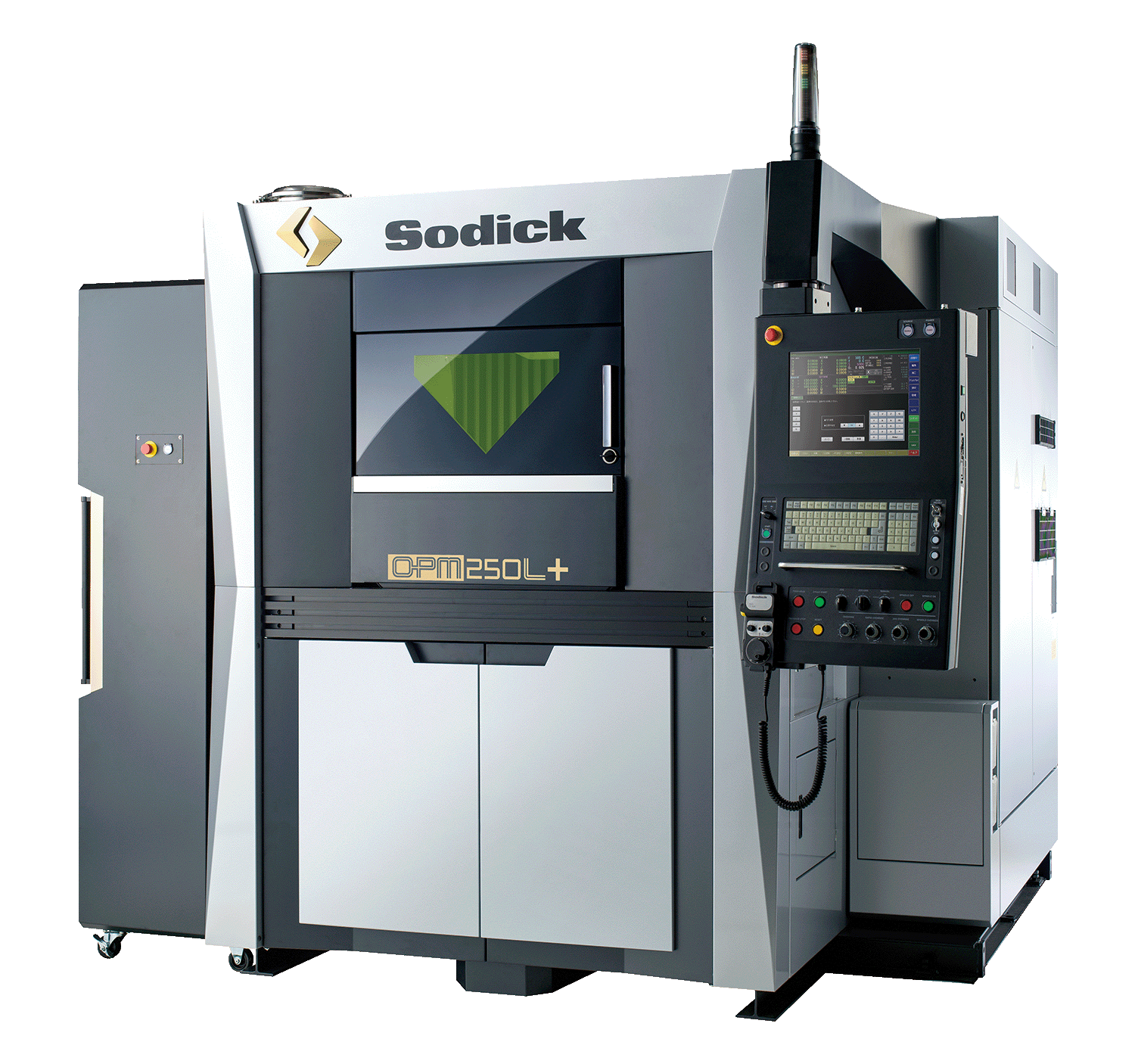

OPM250L+ NEW

Metal Powder Printing and High-speed Milling Finishing Can Be Handled by One Machine.

Achieving Further Long-time High-speed Stable Printing, Supporting Multiple Powder Types, and Improving Operation Rate

* The picture shown may slightly differ from the actual machine.

Main Features

- Achieving Both High-speed and High-quality Printing

- Options are available for dual laser specifications with two laser oscillators. We also redesigned the printing chamber to achieve the optimum airflow structure and low oxygen concentration environment.

This not only enables stable printing over a long period of time, but also achieves further high-speed and high-quality printing at the same time.

In addition, the high-speed milling function driven by a linear motor drive enables one machine to handle high-precision finishing of laser sintered surfaces. - Supporting Multiple Powder Types

- The cartridge-type MRS,* which is popular in the LPM325S high-speed metal 3D printer, is installed as standard. Replacing an MRS cartridge for each powder type enables material exchange in less than two hours.

Operation using several types of powders can be handled in a short time with a single machine, and the MRS cartridges can be shared with the LPM325S, which contributes to space-saving at the printing site.

* MRS (Material Recycle System) : Unit for automatic powder supply/collection, and automatic powder sieving - Improving Maintainability and Operation Rate

- We have developed an in-house fume collector that removes and cleans accumulated metal vapor (fume) generated during laser machining. The ability to collect fumes during operation has been greatly improved, and the frequency of maintenance has been reduced to about one-half of that of conventional machines.

In addition to the print monitoring function, which can monitor the printing condition on the NC display, the Melt Pool Monitoring (optional), which enables direct monitoring of the molten state, achieves stable printing.

Special Site

Products

| Max. object size W×D×H (mm) | 250 x 250 x 250 |

|---|---|

| Axis X × Y × Z Travel(mm) | 260 x 260 x 250 |

| Max. workpiece loading weight(kg) | 120 |

| Max. laser output(W) | 500 |

| Spindle rotation speed (min-1) | 6000 ~ 40000 |

| Machine dimentions (w/o Peripheral equipment) L×W×H (mm) | 1920 x 2270 x 2000 |

| Metal Powder *1 to 3 | ULTRA21 (Maraging Steel) OPM HYPER1 (Cobalt-free Maraging Steel) SUPERSTAR21 (SUS420J2) SVM (Original Special Steel for Molds) OPM STAINLESS 316 OPM STAINLESS 630 CT PowderRange Ti64 F (64 Titanium) CT PowderRange 718 F (Inconel 718) CT PowderRange CCM F (Cobalt-chrome) CT PowderRange AlSi10Mg F (Aluminum alloy) MA-CCR25L (Copper alloy) |