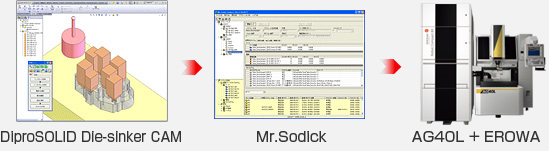

DiproSOLID Die-sinker CAM

Fully Exploits 3D Design Models to Significantly Reduce the Burden on the Operator

CAM System for the Machine Shop that Eliminates Human Error

Main Features

Extract the Machining Positions from the Model

Extract the Machining Positions from the Model

Positioning of Workpiece and Centering of Workpiece and Electrode

The centering measurement points are determined from the 3D solid model, which eliminates incorrect entry of coordinates.

This provides a powerful tool especially in machining processes using multiple electrodes in an ATC.

Compatible with Various Machining Methods

DiProSOLID is compatible with machining including roughing, semi-finishing, and finishing with a single electrode at multiple processes, and pitch machining while moving an electrode with multiple discharge positions.

Multi-Step Electrodes

Pitch machining

Optimal Machining Conditions

The workpiece shape determined in the STL data output from a 3D solid model or cutting simulation is used to calculate the discharge projected area at each machining depth and investigate the optimal machining conditions.

Electrode Dimensional Correction

The system corrects for dimensional errors that occur during electrode manufacture.

Corrections are made in the X, Y, and depth directions for each electrode.

NC Program

Creates an NC program that includes all workpiece positioning, electrode centering, and machining.

During the centering process, if the difference (actual measurement error) exceeds the tolerance, centering is halted to prevent errors.

NC Simulation

Simulation of the processes from centering to machining allows dry runs to be eliminated to significantly reduce the check work before starting machining.

Creates Machining Instructions

Creates machining instructions in HTML format from the defined machining information.

Referring to the machining instructions at a PC terminal in the machining site allows easy, error-free setup work.

Run-On Machining

Creates an NC program for run-on machining from the measurements after machining.

Automated System Support

The combination of an ATC, APC, 3D measuring device, and Mr. Sodick (machining process scheduling system) supports the configuration of an automated system.

Product Introduction with Video Clips

「DiproSOLID Die-sinker CAM」

The Camtasia Studio video content presented here requires JavaScript to be enabled and the latest version of the Macromedia Flash Player. If you are you using a browser with JavaScript disabled please enable it now. Otherwise, please update your version of the free Flash Player by downloading here.