Aseptically-packaged Cooked Rice Production System

Safe, reliable deliciousness with hygienic manufacturing systems

Sodick's aseptically-packaged cooked rice production system are conceived from our desire to provide rice as delicious as that cooked at home.

We have achieved a high level of safety by designing systems that are capable of completing production starting from washing rice through to finishing the product with almost no human intervention.

Main applicationsAseptically-packaged cooked rice, chilled rice |

|

Comparison of Aseptically-packaged cooked rice and retort cooked rice

Sterilization Time for Aseptically-packaged Cooked Rice Shortened to Around 40 Seconds!

- Aseptically-packaged cooked rice is packed with attention to preserving the "freshly-cooked rice" flavor.

The cooking by steam brings out the inherent delicious taste of the rice. - Since it has a long shelf life, it can be used as emergency provisions.

| Aseptically-packaged cooked rice | Retort cooked rice | |

|---|---|---|

| Sterilization method |

Sterilization by directly applying high-temperature steam to the rice grains

|

Sterilization by applying high-temperature steam after packaging

|

| Sterilization time |

40 seconds (short time) |

30 minutes (long time) |

| Effects on food materials |

Little damage caused by virtue of short-time heating |

Substantial damage caused by overheating |

Explanation of the production process for Aseptically-packaged cooked rice

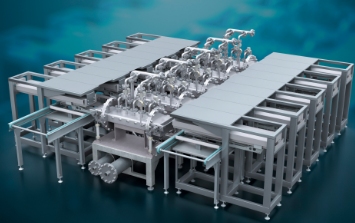

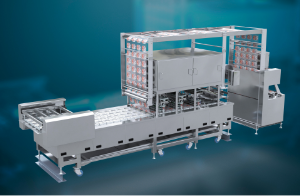

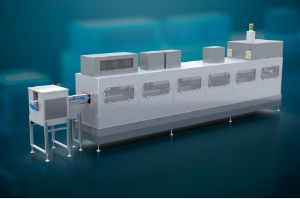

Layout for Aseptically-packaged Cooked Rice Production System

You can view details on each equipment by clicking on its title.

Process 1 Rice Soaking Equipment

Polished rice is conveyed into soaking tank and soaked for around 60 minutes to add water to the rice.

At the same time, contaminants and foreign matter are removed.

Process 2 Container Feeding / Rice Filling Equipment

Rice that has been conveyed to the hopper of the rice filling equipment is introduced into the supplied containers in fixed weights calculated as single servings.

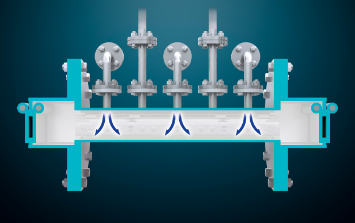

Process 3 High-Temperature Pressure Sterilizer

Single-portion rice filled in containers are loaded into the High-Temperature Pressure Sterilizer.

They are sterilized at maximum pressure of 0.35 MPa at around 145℃ for approximately 40 seconds.

By repeating the injection and vent of steam in succession of 4 to 6 times, the rice is evenly sterilized under pressure and heat in a short time.

Process 4 Water Filling Equipment

Water whose pH has been adjusted in pH adjustment tank is added to the sterilized rice in the containers.

Measuring tolerance is within 1%.

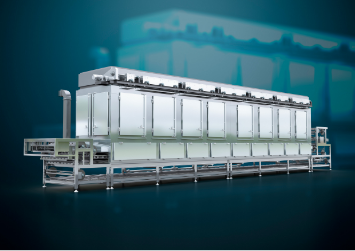

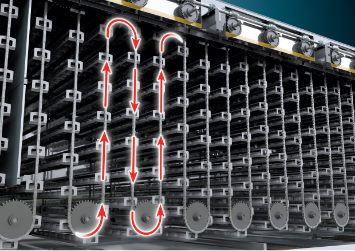

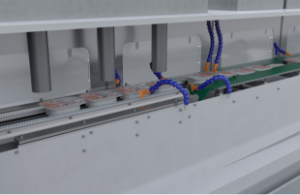

Process 5 Rice Cooking Machine

Rice in containers is loaded into Rice Cooking Machine and cooked at around 98 to 99℃ for approximately 30 minutes.

It uses a gondola system, and the retainers continually move from the top to the bottom and from the bottom to the top.

Process 6 Sealing Equipment

Sealing in clean room

Ultraviolet sterilization and filling with nitrogen are available as options.

Process 7 Steamer and Cooler

Steaming for approximately 80℃ for around 15 minutes, followed by water cooling

The steaming process (secondary sterilization) improves the flavor and appearance, and is also very important for reliability and safety.

Process 8 Water Draining Equipment

Water adhered to the containers during water cooling is removed by the water draining equipment.

Water clearance is achieved efficiently even at difficult locations, such as the seal faces at the top, bottom and sides, with specially designed blowers.

Process9 Leak Tester

This is the process of checking whether the container is airtight sealed.

This is the final quality check process after passing through a metal detector, X-ray inspection device, and weight checker.