History of Sodick

Part 1: Founding and Before to Phase of Technical Development &

Remarkable Growth

Founding and Before (1960 onwards)

First in the world to develop the technology that unlocks the practical application of electrical discharge machines

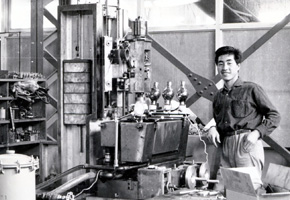

Immersed in his experiments

(Toshihiko Furukawa around mid-1960)

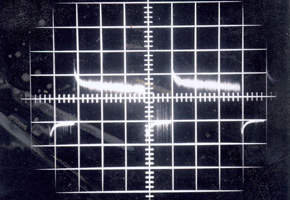

The discharge waveform of

the non-wearable electrode circuit

discovered by Toshihiko Furukawa

(reverse polarity, long-pulse)

During World War II, the Lazarenkos, a husband and wife team of scientists in the former Soviet Union, first discovered electrical discharge machining, which made it possible to machine very hard metals and to produce complex machined shapes in ways not possible using conventional cutting tools. In post-war Japan too, manufacturers awaited the practical application of this technology.

In the late 40s and early 50s, it became possible to manufacture EDMs in Japan, but the technology was still beset by a range of problems. Machining was very slow and the finishing very coarse. The high level of wear and tear on the electrodes meant that faster machining speeds could not be achieved and the only practical application for machines was to drill holes in very hard metals.

Around 1960, Sodick founder Toshihiko Furukawa, then a young man in his 20s, was working for a domestic machine tool manufacturer in Tokyo (the former Japax, Inc.) while also studying electrical theory at university in the hope of finding a way to overcome the technological issues with EDMs. It was a very busy time for him, spending day after day on repeated experiments.

In 1963, his hard work led to the discovery of the "Non-Wearable Electrode Circuits*1", the principle of which was described in his thesis.

Due to the fact that electrical discharge machining research in Japan was in its infancy at the time, Furukawa's discovery was not widely recognized. But, rather than being discouraged, he returned to his research, and as a result successfully developed the world's first "non-wearable electrode transistor power supply".

Subsequently, he went on to develop the "Loran machining method*2", which allows the sides of a workpiece to be very accurately machined to the desired measurements.

The extreme difficulty of development process meant that it took 5 or 6 years to complete, but Furukawa, knowing how difficult the practical application of EDMs would be without this technology, persisted with his research until he finally succeeded in developing the new method.

These discoveries and developments, by resolving the problems with machining accuracy and with the finished surface, paved the way for the rapid uptake of EDMs and revolutionized the world of metal machining.

*1 "Non-Wearable Electrode Circuits": An electrical discharge machining circuit in which the electrode is not consumed.

*2 "Loran machining method": An electrical discharge machining method in which the workpiece surface is finished by moving the downward-pointing electrode back and forth and from side to side very precisely to achieve concurrent surface finishing along both axes.

Visit this page for more details of this technology.

- How did you come to be involved with electrical discharge machining?

-

Furukawa

Actually, it was my father who first grappled with the problem of turning EDMs into a practical reality. I used to take him to and from his old factory in Kawasaki every day on my bicycle.

I remember seeing the metal cutting machine sending sparks flying everywhere as it drilled holes in metal bars. I started out in a different job, but I was drawn back to this work. It seemed more interesting somehow. So I ended up in the field of electrical discharge machining.

- Attending university while you worked, you wrote your thesis on non-wearable electrodes. Did you use what you learned at university in your thesis?

-

Furukawa

During the 50s and early 60s, it was completely normal to study and work at the same time. Everyone studied at night. To answer the question, I had to do my own studies since the university had very few books on the principles of EDMs. And after I made the discovery, it still wasn't recognized even within the company, so I built a trial machine that I took to a customer's factory so they could try it out.

Furukawa

During the 50s and early 60s, it was completely normal to study and work at the same time. Everyone studied at night. To answer the question, I had to do my own studies since the university had very few books on the principles of EDMs. And after I made the discovery, it still wasn't recognized even within the company, so I built a trial machine that I took to a customer's factory so they could try it out.

- I've heard that you discovered the non-wearable electrode circuit by accident in the course of carrying out repeated experiments?

- Furukawa Yes, that is true. Even now, it seems really amazing. I was machining as usual, changing the conditions to gather data, and at some point the copper electrodes turned completely black and there was a neat hole drilled in the machined steel plate. I was absolutely amazed. I'd repeated the experiment any number of times and had never had any success, and now I'd succeeded completely by accident. Even now, I think that accident must have been fate -- a gift sent from heaven. Without that discovery, I'm sure the development of manufacturing would have been much slower.

- How did people around you react when you discovered the non-wearable electrode circuit?

- Furukawa I didn't get any recognition from my superiors or from the company, but I was surely convinced that the non-wearable electrode circuit would be useful for EDMs, so I refused to give up and carried on with my research.

- How did your customers react to the discovery?

- Furukawa

They were really pleased, because it allowed them to do things they hadn't previously been able to do.

At that time, when they made molds for glasses, they were using a power supply built into an apple crate.

Up to then, they'd had to split the molds in two, which left a seam running down the middle of the product. But having the ability to machine the mold without splitting it meant they could make products with no seam.

Later on, one of our customers gave me a gift of a diamond-cut drinking glass.

- After that, the technology you'd worked so hard to discover was spread to other companies. Wasn’t that frustrating for you?

-

Furukawa

No, not at all.

Making the discovery isn't really that big a deal, I think. You don't get recognition from people just for that.

Maybe after you die, people might say, "Yeah, he was pretty good".

The world is a funny place. You might make something good by yourself, but it won't be recognized in that way.

In my opinion, recognition comes when competitors start to appear and they say, "if only we could beat that".

- I'm told that the development of the Loran machining method was very difficult.

-

Furukawa

It was extremely hard.

When you drill a hole in the workpiece using a square electrode for instance, the electrode makes a square hole because it's using transfer machining. And because the discharge is electrical, the tip of the electrode moves down rapidly, machining new material as it goes. It machines downwards, but because it doesn't touch the sides, it leaves behind a lot of surface roughness. So to finish the sides, we then use an electrode that is slightly larger and repeat the machining from the beginning.

This is all fairly easy with a square electrode, but for complex shapes, it's a lot of trouble making multiple electrodes that are all slightly different in size. Then I wondered whether we could get the same result with just one electrode or not. But we realized that if you only use one electrode, you have to be able to move it sideways to machine the sides. So, we came up with an idea – it's more like we oscillate the electrode without rotating it. That way, we could vary the machining parameters. And this would lead to producing nicely machined side surfaces.

So, Loran machining gives us nicely finished cavity surfaces both at the bottom as well as on the sides. This might sound simple, but it is very difficult to always maintain a fixed gap between the electrode and the workpiece material during Loran machining.

- What other developments did the Loran machining

method lead to? -

What needs to be done to maintain a fixed gap during Loran machining?

Furukawa

The real, practical problem was that moving the table in exactly the same way is very difficult. It gradually slips out of alignment. In Loran machining, the tables used gradually slipped out of alignment due to the effects such as backlash. It was really difficult to maintain exactly the same position in Loran machining after 100 or 200 processes.

What needs to be done to maintain a fixed gap during Loran machining?

Furukawa

The real, practical problem was that moving the table in exactly the same way is very difficult. It gradually slips out of alignment. In Loran machining, the tables used gradually slipped out of alignment due to the effects such as backlash. It was really difficult to maintain exactly the same position in Loran machining after 100 or 200 processes.

From the customers’ point of view, they would make products and then find that products were different during the finishing stage, which made them pretty upset. So we needed to be able to move the electrodes without the table slipping, and until we managed it, things were really tough.

But by using this machining method, we were able to machine using just one electrode and significantly improve the accuracy of electrical discharge machining.

However, this created another problem in terms of the workload on the operator, who had to cope with lots of different machining parameters.

To get the best possible outcomes from the Loran machining method, we needed a control system that could be programmed so there would be less work for the machinist. That led to the development of NC machines. Without this technology, I don't think we would've been able to build NC EDMs.

- Then, the impetus for this was to provide something that would be useful for society, yes?

- Furukawa

Well, I wasn't doing it for the money.

With one good innovation, the impossible becomes possible. And by repeating that, I think we can move forward.