History of Sodick

Part 3: Technological Innovation / Enhancement Phase

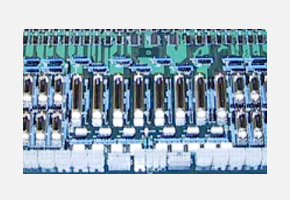

The Development of the Motion Controller

Motion controller

There eventually arose the need to come up with new technologies to control motors with commands from the NC units—a product developed when the Company was founded—in order to increase precision.

Sodick thus decided to establish in February 2000 a development subsidiary in San Jose, California, called Sodick America Corporation.

The Company achieved a major innovation in its machine tool technology when it developed its own motion controller, the K-SMC, and equipped its products with it. Its use lead to dramatic improvements in control precision and responsiveness, and also made it possible for Sodick to develop and produce the NC units, motion controllers, and linear motors needed to control machine tool drives.

Sale and Development of Consumables

With the expansion of sales channels, the Company also undertook the development of consumables.

In March 1982, Sodick came up with V, a special high-performance machining fluid that greatly increases the speed of electric discharge machining processes.

Sodick began the sale of consumables in earnest after having developed this product, founding that June a subsidiary initially called KHS.

At first, KHS sold mainly imported or purchased consumables for use with Sodick machines, but eventually in response to customer demand the Company developed its own peripherals, the Jumbo Feeder and the L-Cut.

Today, more than three decades later, the Company sells such products as its wire guide developed by a Group company and has developed the recyclable wire electrode to maximize the performance of Sodick electric discharge machines.

Sodick has taken further steps toward being environmentally friendly by coming up with recyclable filters and ion-exchange resins, and also provides an abundant lineup of other peripherals.

With the advantage that being the only EDM manufacturer to produce and sell consumables, Sodick is proudly developing products that are optimized for its own equipment and useful to its customers.

- Around this time, you also developed new products and consumables, including the linear motor and motion controller which are the Sodick core technologies. What made it possible for you to come up with them in such short order?

-

Furukawa

The key was in not giving up.

Furukawa

The key was in not giving up.

I think our engineers are always drawing pictures in their heads of what they want to do. Most people give up when they can’t do what they want to. But our engineers at Sodick are not the kind of people who quit halfway through.

If you have the confidence that comes from having good colleagues, being able to do most things by yourselves, and having the right atmosphere in place, you aren’t going to give up.

- Of all the core technologies you’ve developed to date, was there one that you had thought just wasn’t going to be possible?

- Furukawa

When I start to do something, I do it because I can already see what lies ahead.

I’m always saying that it’s okay if it takes time, so there hasn’t been anything that was impossible even though we might have needed some time for it. I don’t think I’ve ever told people to do something without being able to see our destination. I don’t start on something that doesn’t seem reasonable.

- Hearing you say this makes me think it must be a good environment for your engineers.

- Furukawa

I think so. There aren’t many companies like ours where they get to do things freely.

If they are working properly toward some goal, I’ll always support them so long as they aren’t taking the wrong path.