Cost reduction in modeling

with large metal 3D printers

Ensuring quality products through residual stress analysis

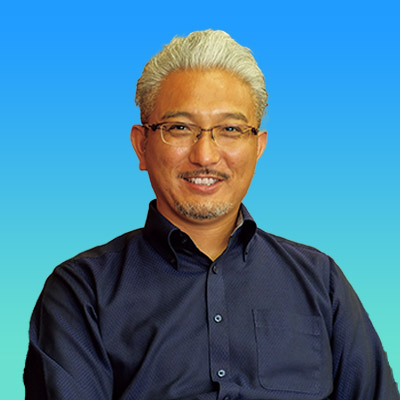

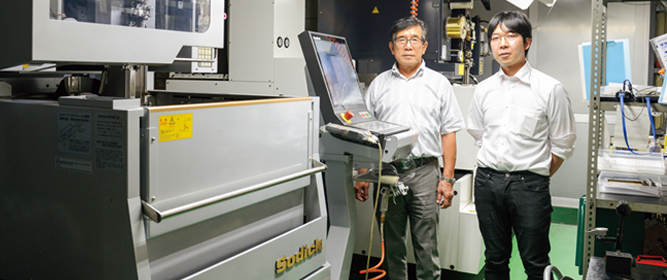

The introduced Sodick metal 3D printer LPM450 (photo foreground)

The introduced Sodick metal 3D printer LPM450 (photo foreground)

Nihonseiki Co., Ltd., which handles die-cast molds such as cylinders and engine blocks, is advancing technology development for improving cost competitiveness and ensuring quality through large-scale nested modeling using metal 3D printers. By utilizing a large powder-bed-type metal 3D printer introduced last year, we aim to reduce costs through multiple piece extraction. We are analyzing tensile residual stress generated during modeling to establish optimal modeling conditions for difficult-to-model large workpieces.

We introduced Sodick's large metal 3D printer LPM450 in September 2024 to a subsidiary that manufactures AM components. It can print up to 450mm in size and is equipped with an optional build monitoring function that uses cameras to monitor each layer and check for the occurrence of melt pools.

The aim of the introduction is to support large inserts for giga-casting applications while reducing costs. Masato Matsubara, Executive Director & COO, says, “Unlike machining centers (MC), printers are machines where large can accommodate small. Costs can be reduced through multi-piece printing.”

For example, even large MCs have only one spindle, so machining time is limited to the spindle's operating time. However, the introduced LPM450 has four lasers (optional), allowing efficient printing of multiple pieces at once, even with workpieces of different shapes.

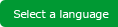

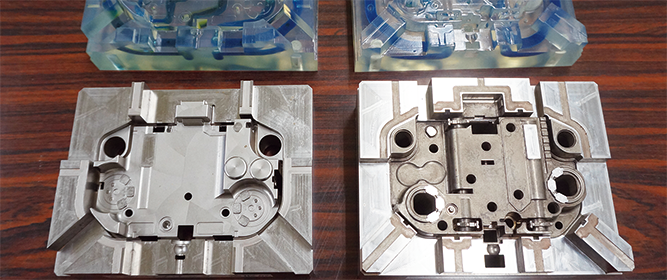

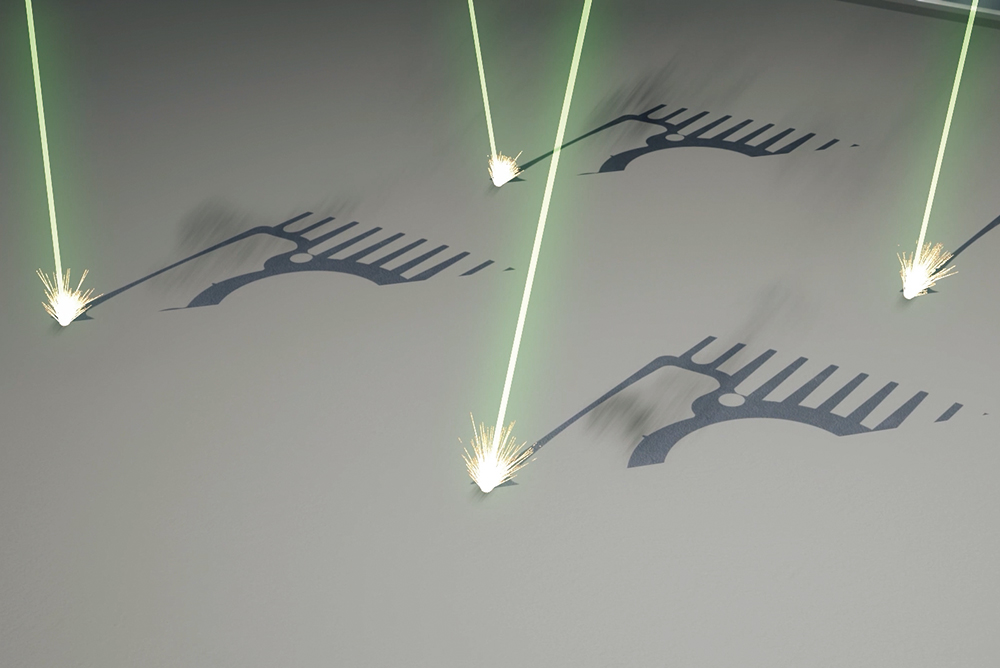

The LPM450 can be equipped with four lasers, enabling higher speed and greater efficiency (image).

The LPM450 can be equipped with four lasers, enabling higher speed and greater efficiency (image).

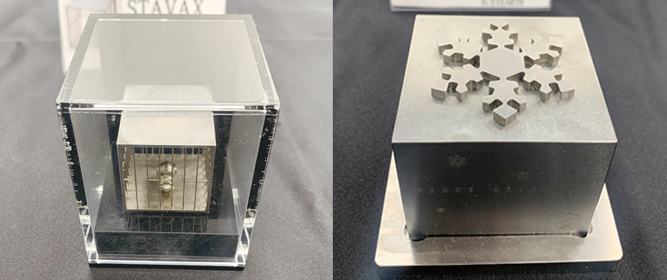

For example, a mold for a water jacket measuring 413mm wide × 177mm high (bottom right photo) was printed simultaneously in three pieces. “By reducing setup changes, we were able to lower costs from over 2 million yen with a single laser to about 1.5 million yen. Although slightly more expensive than cutting alone,

it leads to cooling effects and extended mold life, allowing us to compete by reducing the total cost of molding.”

While enhancing cost competitiveness in the way, we address the challenge that large workpieces are prone to cracks and fractures during printing and post-processing. During powder melting and solidification, tensile residual stress occurs due to the shrinkage difference between the solidified part and its surroundings.

High tensile residual stress makes cracks more likely during printing and heat treatment. In particular, the SKD61 equivalent material used by the company “has advantages such as high thermal conductivity but is more difficult to print with.”

Therefore, we work on identifying the mechanisms of cracks and fractures and establishing optimal printing conditions. An important factor is the measurement of residual stress.

Residual stress is analyzed using X-ray residual stress measurement equipment. “We were able to identify at what depth from the build surface residual stress occurs, and with what magnitude. We print using the threshold where printing quality stabilizes, adding know-how such as post-printing cutting and heat treatment to provide optimal inserts.” However, since the analysis to date has been conducted on small workpieces under 200mm, we are currently rushing to measure and analyze large workpieces and establish optimal printing conditions.

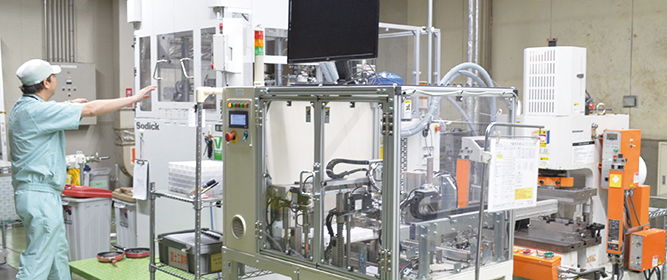

Exhibition at the Sodick booth at MECT2025

Exhibition at the Sodick booth at MECT2025

The reason for this strong focus on printing quality and conditions is that “to expand the adoption of inserts from metal 3D printers with high cooling effects, a technical definition of 'what constitutes a good product' is necessary.” “In mold materials, a mill sheet must be submitted. Saying 'we don't know because it was printed' is not acceptable for printed inserts.” Going forward, we will continue to tackle the challenges inherent in printer-based building, namely reducing costs while ensuring printing quality.