Interview【Sodick User Report】 Kaga-gun, Okayama Prefecture

Kibi NC Training Center Corporation

Specialists in precision electrical discharge

Company that aims for "social independence from the mental and economical aspects" targeting "people with disabilities" using the latest machines

Improvement in both security and efficiency of stable quality

Mr. Katayama, the President proudly says "let us handle anything regarding EDM, from the machining of metal components to superalloy components." When taking a tour around a factory, there are products of various shapes. It is surprising that there are some products machined by exceptional methods that have never been seen before.

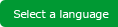

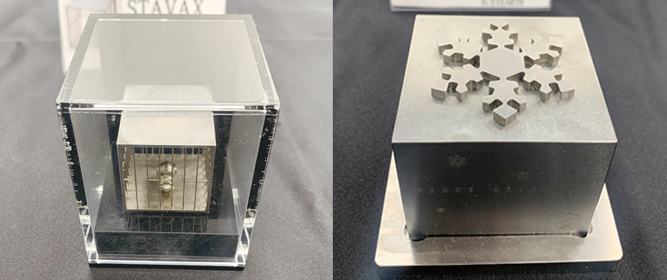

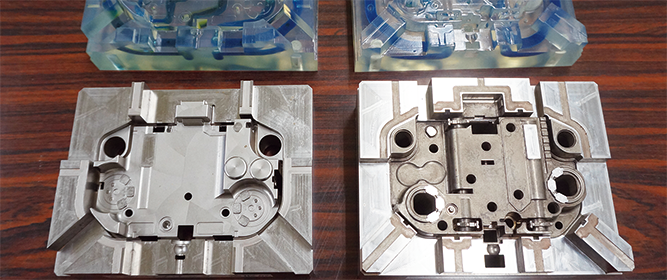

There is the machining of molds targeting 2 to 3 μm, such as components of rubber molds, die-cast molds, and progressive press dies. There are various methods to machine components, and there are machining tools that have been manufactured making full use of electric discharge for the jet nozzles of gas engines, hard metal nozzles for machine tools, gears of inscribed gear type pumps, and graphite electrode machining for the manufacturing of torque converters, and are machined by interesting methods.

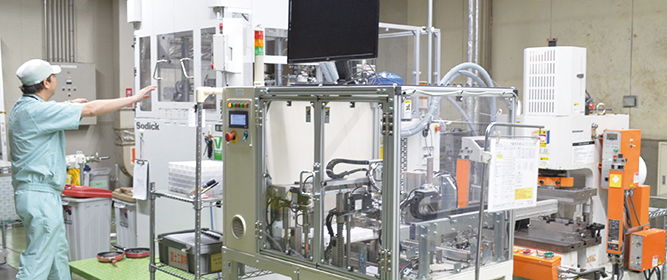

In the machining of some components, it can be seen that workpieces of the same shape are aligned in the overall machining tank, and machines that steadily performs multi-cavity machining. It is obvious that this production site can promote improvement in both the security and efficiency of stable quality.

There is another reason why this company performs such various machining methods.

It's "carrier development training for people with disabilities."

Training for people with disabilities specialized in EDM

The Kibi NC Ability Development Center is a quasi-public corporation which was established in 1982 for the purpose of training handicapped persons in the use of the latest technology. According to President Katayama,

it was the first center in Japan to be established for training handicapped persons in the latest technology.

From the time that the Center was established, it has possessed a production machining department and a training department. The strength of the production machining department lies in its precision machining.

In contrast, the training department is divided into the CAD/CAM sub-department and the precision machining sub-department, and here training of handicapped persons in the latest technology is carried out for a period of two years. Over the last 30 years, a total of at least 81 persons have been sent to industry.

In 1988, “Onik,” whose strength lies in its electrical discharge machining, was established based on the philosophy of the necessity of finding employment opportunities for persons who have undergone training. Subsequently, “Okayama Harmony” was established as a subsidiary of Onik to carry out polishing and other processing. The running of this company is promoted by the entire group.

At present, the total turnover for these three companies is as high as 400 million yen, or so. President Katayama says: “The purpose of our company is to train handicapped persons. However, in order to realize this it is also necessary to earn money as well.” The fact that the Kibi NC Ability Development Center has a high awareness of profitability despite being a quasi-public corporation is also borne out by President Katayama’s words: “A private corporation is severe and moves quickly, and it is necessary to maintain direct contact with new information and society.”

In addition, in the case of the Kibi NC Ability Development Center, these customer corporations can also conceivably accept our trainees.

The reason for specializing in EDM is that it is "safe and secure for operators." There are few opportunities to handle tools with sharp blades in the EDM compared to other cutting machines.

For this reason, we can comfortably entrust work to people who have physical impediments. The slower operation of the machine is another important point compared to cutting work.

In the setup work, there is no remarkable time difference compared with the non-disabled people of the company. The work progresses satisfactorily based on the proper scheduling of each task, such as the person who performs positioning only, and the person who operates multiple EDMs alone.

Particularly, in multi-cavity machining which utilizes the overall area of the machining tank, highly efficient production is being performed utilizing the merits that can only be provided by a linear motor drive machine, which realizes stable and high precision machining throughout the entire machining area to the utmost.

Also, The Kibi NC Training Center promotes employment of disabled persons as well as acquisition of professional knowledge and technology, and also provides a place of work where the technology can actually be demonstrated, based on the basic policy of "social independence of people with disabilities from the mental and economical aspects."

Sodick also agrees with such activities, and has supported it for more than 30 years.

81 people have completed the training course since its establishment, and play an active role in their place of work across the nation. There are some who participate in the Paralympics as track and field athletes while working.

81 people have completed the training course since its establishment, and play an active role in their place of work across the nation. There are some who participate in the Paralympics as track and field athletes while working.After they attend the two year training course, they can be employed by an affiliated company Onik Industries Ltd.

An environment where the learned technology can be utilized immediately is also arranged in this company.

Personnel who are engaged in work handle both die -sinker EDM and wire-cut EDM, and perform their work efficiently.

Specialists in precision electrical discharge

According to statistics issued by the Ministry of Economy, Trade and Industry, the number of business establishments possessed by die manufacturers in 2013 fell to about 8000 companies, which is slightly more than 60% of the figure that existed 15 years ago. Although the reduced ability to supply dies is also an issue,

it is the reduction of the number of affiliated companies and subcontractors that is inconveniencing the die manufacturers the most. Particularly, there are many persons bemoaning the fact that there are even fewer subcontractors who can carry out precision machining.

The Kibi NC Group, which has as its core the Kibi NC Ability Development Center, possesses overwhelming strength in the field of precision parts, as a specialist in electrical discharge machining. We meet the demands for highly sophisticated and complicated machining of parts, as a partner of die manufacturers.

Our main feature is our ability to provide a wide variety of parts manufactured under subcontract, in addition to our machining technology which realizes a machining accuracy of ±1 μm. We can manufacture virtually anything including injection nozzles, gas turbine parts, progressive presses, and rubber die parts. President Masahiro Katayama says: “So long as there are no restrictions on size, we can meet virtually any difficult demand.”

Our high technical ability is widely recognized, and we receive orders nationwide from major electrical machinery manufacturers, heavy industrial companies, and so on.

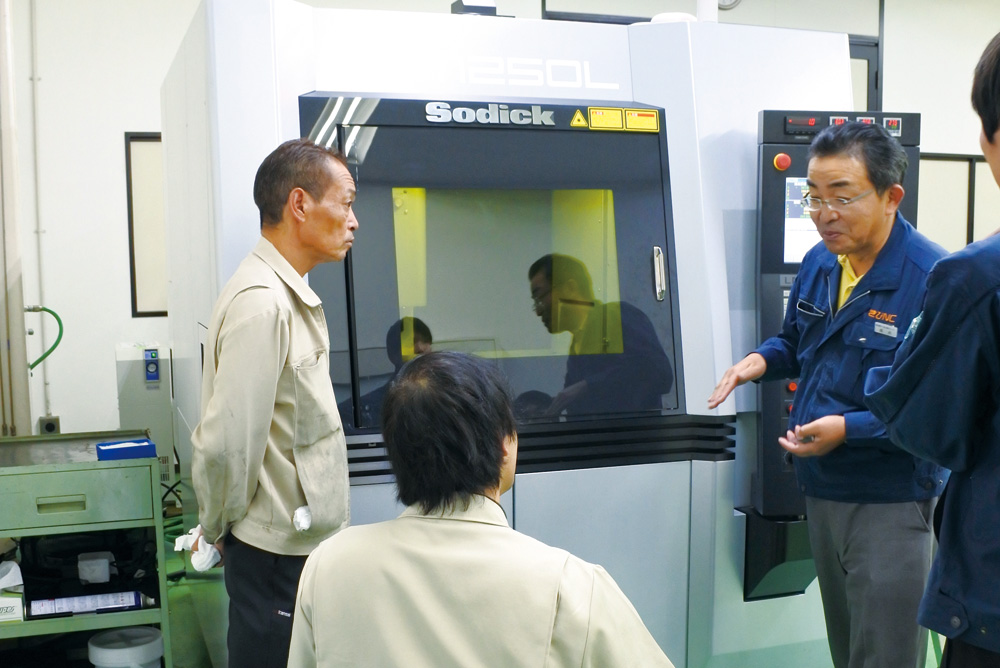

Mr. Nobuo Hisada, manager of the Okayama Business Office of Sodick, which sells electrical discharge machines to the Kibi NC Ability Development Center, recognizes Sodick’s high level of technology through his words: “Even from our standpoint as a professional in the field of discharge machining, we possess superb machining know-how concerning the use of jigs, for example.

Lineup of the latest wire electrical discharge machines

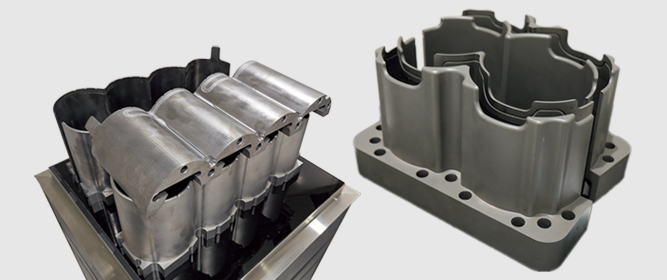

Lineup of the latest wire electrical discharge machinesPrecision Metal 3D Printer Introduction of the OPM250L

Recently, we have also introduced metal 3D printers, and are also strengthening our setup to enable us to not only to carry out electrical discharge machining and polishing, but also to learn about the most up-todate craftsmanship. President Katayama talks about the future. “I would like to accept as many additional handicapped persons as possible from among those who wish to learn about the most up-to-date craftsmanship. And I would also like them to play an active role in society.”

Workpiece made using a metal 3D printer

Workpiece made using a metal 3D printer

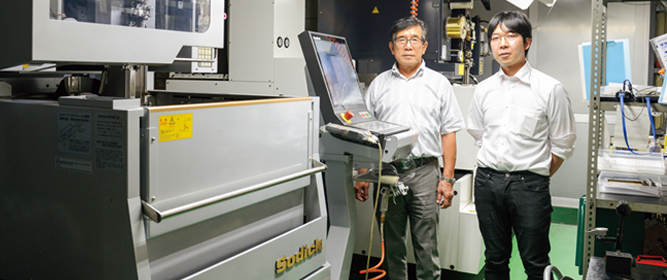

Masahiro Katayama, Representative Director, President

Masahiro Katayama, Representative Director, President

- Representative

- Masahiro Katayama,

Representative Director, President - Established

- 1982

- Address

- 1973 Takebe, Kibichuo-cho, Kaga-gun, Okayama Prefecture 709-2343

- Tel

- 0866-56-8282

- Business Activity

- Training of people with disabilities, commission manufacturing of molds and components, manufacturing and sales o f energy-saving equipment and environmental improvement equipment

- Production Equipment

- [Sodick Products]

Wire-cut EDMs12

Die-sinker EDMs7

Machining centers3

Metal 3D Printer1 - URL

- http://www.kibinc.co.jp(WEB SITE)

- Representative

- Takeshi Namba, President

- Established

- 1988

- Address

- 1973 Takebe, Kibichuo-cho, Kaga-gun, Okayama Prefecture 709-2343

- Tel

- 0866-56-7788

- Business Activity

- Commission manufacturing of molds, precision components and tools, machining development of various products mainly for the machining of PCD and CBN products, and electric discharge machining

- Production Equipment

- [Sodick Products]

Wire-cut EDMs25

Die-sinker EDMs6

[Others] Machining centers3

Surface grinders, others Several machines - URL

- http://onik.jp(WEB SITE)

- Representative

- Takeshi Namba, President

- Established

- 1982

- Address

- 1973 Takebe, Kibichuo-cho, Kaga-gun, Okayama Prefecture 709-2343

- Tel

- 0866-56-7890

- Business Activity

- Manufacture of mold parts and precision parts

- URL

- http://okayama-harmony-a.com(WEB SITE)