Interview【Sodick User Report】 Dongguan, Guangdong Province, China

Homi Dongguan Co., Ltd.

Tremendous Growth and the Secret of This Growth

More than 60 Machines Installed Over a Period of 10 Years

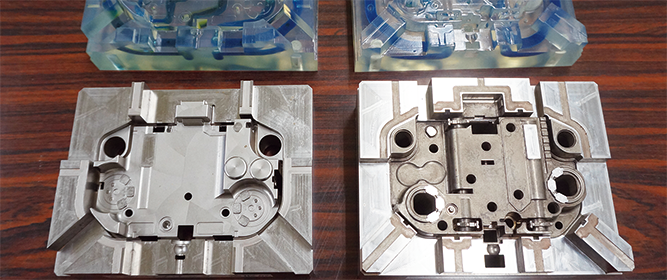

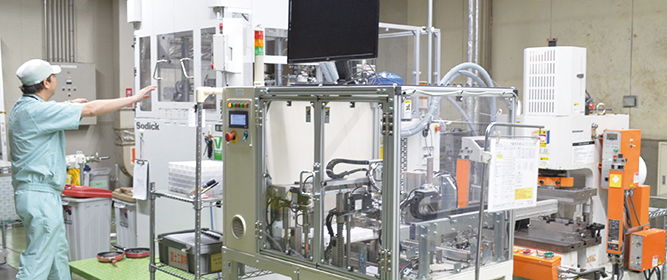

An environment suitable for precision machining was prepared, and a long line of EDMs was installed there. One operator sometimes operates two or three machines. As cross-trained workers, almost all of the operators are skilled at operating wire EDMs, machining centers and also grinding machines. 2017 marks the 10th year since HOMI installed Sodick EDMs, which even now are being used in the pursuit of the most up-to-date precision machining. The motto of Mr. Chang, General Manager of HOMI is: “Do not get drawn into tough price competition. Keep your ear to the ground to establish what kind of manufacturing the user desires, and skillfully ride the wave of the next leading edge from the top.” HOMI is the most enthusiastic company in the Dongguan region.

Introduction

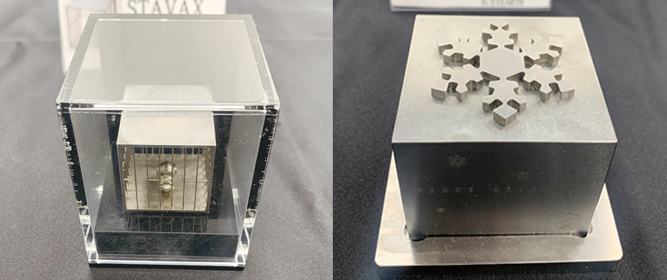

HOMI purchased Sodick machines in 2007. It is a high-growth company which maintains excellent balance between accuracy, delivery time and quality concerning industrial products (die parts, and so on) the final products of which constitute the telecommunication device industry. Many of HOMI’s main customers include major Japanese, European and American corporations, and HOMI receives many repeat orders from them.

There is a thriving manufacturing industry in Dongguan City in Guangdong Province in South China where HOMI is located. The products manufactured here range greatly from precision components for electronic products, for example, to miscellaneous items for everyday use, clothing, and corrugated cardboard for making packing boxes. This city has many factory zones in which the price and quality of these products are stratified in multiple layers. It can be said that the zone in which HOMI is situated one of the most greatly developing zones which maintains its vitality even if factories inside it are adversely affected by the economy and weeded out.

In recent years, in the field of machine tools and industrial machines, a lot of manufacturing of components related to electronic devices such as smartphones is being carried out. Here too, the price and quality can be freely selected. There are at least seven major companies manufacturing smartphones, which are final products, in Greater China.

Also, a total of more than 400 million smartphones are sold each year. Consequently, there are a huge number of sales outlets in every commercial street in every town.

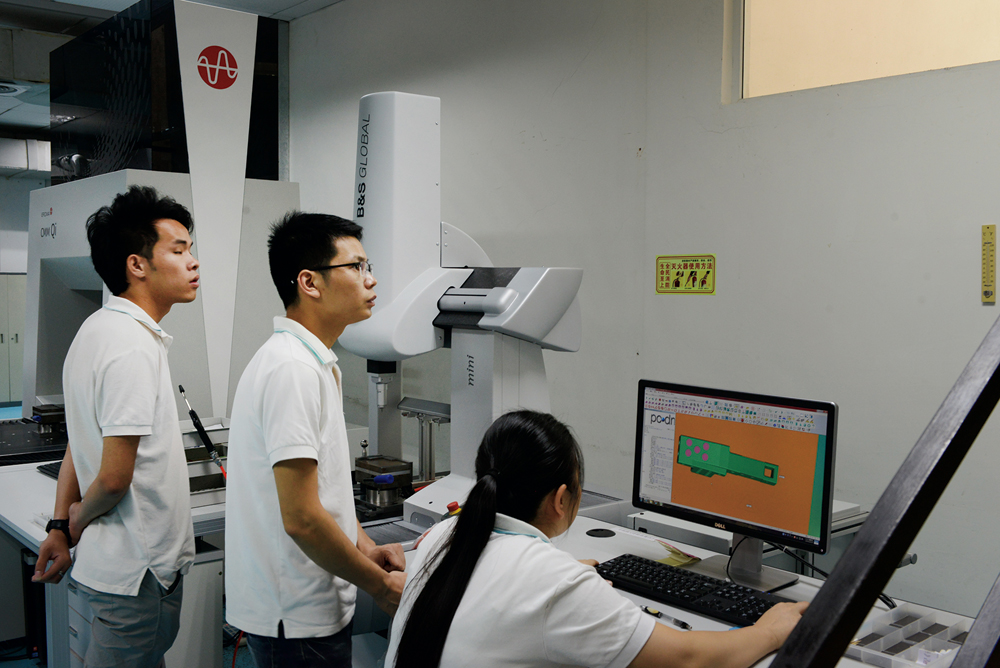

From the time when HOMI, which is well-acquainted with the characteristics of machine tools, purchased Sodick machines in 2007, it already had the perfect response to the important point concerning precision machining, namely “how best to control the ‘heat’ at the machining site.” At the various parts of the machines that constituted sources of heat, thoroughgoing steps were taken to ensure that this heat was discharged to the outside of the building and also measures were devised to minimize temperature changes at the machining site, thus realizing the optimum facility environment. Regarding machining centers and 3-dimensional measuring instruments as well, the thoroughness of these heat elimination measures which take into consideration the characteristics of these facilities is quite remarkable. According to HOMI, “the increasingly high demands placed on manufactured products can be met by installing high-repeatability linear motor drive type machines made by Sodick, and thus permit high machining repeatability at the machining site at any time.”

With the arrival of 2017, HOMI has entered its 10th year. At the time of its establishment, it purchased machines made by Sodick and set about manufacturing parts for dies used to manufacture top view LEDs.

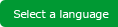

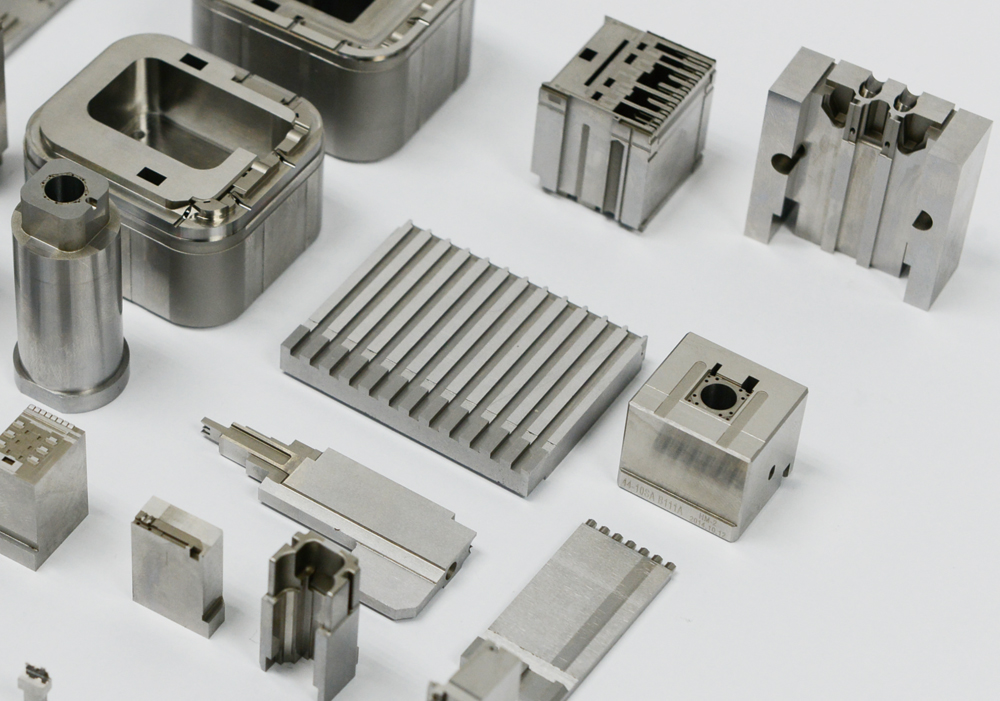

It also set about manufacturing parts for dies used to manufacture side view LEDs in cooperation with the industry which was aiming at realizing greater brightness and miniaturization. HOMI was active in fields where the demand for accuracy is high, such as the manufacture of dies for making lenses (photo). Although HOMI has now entered the 10th year since its establishment, the Sodick machines that it uses maintain the same accuracy as that when they were first purchased. In addition, HOMI’s employees are working hard with a view to taking up the challenge of craftsmanship, aiming that realizing even higher accuracy.

The manufacture of dies for making

lenses

The manufacture of dies for making

lenses The manufacture of dies for making

lenses

The manufacture of dies for making

lensesFostering talent − Features of employee training

One major issue related to the advance of overseas companies into China is the fostering of talent. It consists of the awareness among employees of the improvement of workability, ability and efficiency and also their fixation ratios.

HOMI realizes all of these points.

Based on a coherent management policy, HOMI’s setup for improving all of the above has continued ever from since HOMI’s establishment. HOMI has many staff, both male and female, in their 20s and 30s. A glance at the employees working in the office and also in the factory enables one to appreciate just how the seriously they are engaged in their work. Because HOMI’s business is based on global transactions, the staff in the administration department are bilingual, and are fluent not only Chinese but also in English or German as well.

In the factory there are many staff in their 20s. Many of these are graduates of technical high schools in Wuhan. According to HOMI, this is because “staff who are interested in craftsmanship from a young age and are familiar with the method of operating machines quickly become familiar with the worksite, thus laying the foundation to enable them to carry out their work seriously and with a sense of purpose.” In this region where manufacturing industry is thriving, the adoption of a solid and coherent management policy should result in a strong company that is unaffected by changes in the economic situation, thus enabling HOMI to offer superior accuracy and quality compared to other companies. General Manager Chang says: “We have a setup under which the employees receive a salary that is commensurate with their ability.” All of the employees are aware of this, and take pride in the fact that the level of their work is above standard.

One can feel the enthusiasm of the staff by listening to what they say concerning the joy of craftsmanship, such as the following: “Let’s make something good” and “Next time, let’s try something a little different.” Their eyes are full of life. You can sense this by making an actual tour of inspection of the worksite. This worksite enables you to feel the seriousness with which the workers approach craftsmanship.

There is another reason why many staff are in their 20s. In the coastal regions of China, there are many young persons from the Inland areas in China who have come looking for work. This situation exists here in Guangdong as well. However, when these persons reach their 30s and settle down, many of them return to their country villages to look after their parents.

Previously, this was also the case at HOMI. However, many of the engineers came from Wuhan, and although they wanted to return to Wuhan it was rather difficult for them to find work there. To overcome this situation, General Manager Chang established a factory in Wuhan as well, installed machines, and employed staff.

General Manager Chang proudly showed off saying “This factory has eliminated worries by family members and unease concerning the future, and thus enables the staff to work with peace of mind.

Involuntarily, I nodded deeply. In actual fact, it is fair to say that there is no reason for HOMI to construct a factory in Wuhan. HOMI has no clients in Wuhan, neither is it a suitable location for procuring materials. In the first place, HOMI procures almost all of its materials from Japan which has a solid reputation for quality. Although automobile manufacturing is thriving in Wuhan, there are currently only a few manufacturers who produce parts with high added value such as small, precision parts, which are HOMI’s forte.

General Manager Chang is indeed a dynamic person. Even after completing this assignment, I heard many times that the reputation of HOMI in this region is admired by many people.

By installing a total of more than 60 Sodick EDMs and machining centers, HOMI has greatly speeded up delivery of its products and also significantly improved its production capacity. HOMI’s main factory collaborates with the Wuhan factory in which are installed many machines of the same models as those in the head office, resulting in further expansion of HOMI’s operation. I asked General Manager Chang about his next target. As of 2017, General Manager Chang who comes from Taiwan has already started construction of a new office in Taiwan which is intended mainly for carrying out research and development and also design. Here, more global activities will be carried out, and also the office is intended to function as a central organization for accumulating HOMI’s technology and know-how. Everybody is eagerly awaiting the opening of the new Taiwan Office.

Representative

RepresentativeLeo Chang

- Representative

- Leo Chang

- Address

- Yucheng road11 A area 2F,

Shatou Xinsha Industrial district,

Chang' an town, Dongguan city, Guangdong. - Tel

- +86-769-8150-5333

- Production Equipment

- [Made by Sodick]

Die-sinker EDM AD30L

Wire-cut EDM AG400L

High Speed Milling Center HS430L

[Other Machines] Profile grinding machines, and so on