Interview【Sodick User Report】 Kariya City, Aichi

IG EVEARTH CO., LTD.

Promoting DX and Automation at the New Plant

Entering the Medical Field Leveraging Years of Expertise in High-precision and Micromachining Technologies

Wide-reaching Trust in Sodick EDMs

For over 65 years since its founding, IG EVEARTH (Kariya City, Aichi) has specialized in the production of diverse molds for automotive parts.

Building on its expertise in drivetrain prototyping, the company has recently diversified into new sectors, including the medical field. The company has accelerated efforts in digital transformation and automation, centered around its new factory, which became operational in 2023, underscoring the company’s evolution as a “next-generation leader in mold manufacturing”.

Sodick’s EDMs form a cornerstone of its electrical discharge machining operations, reflecting a strong level of trust in their capabilities. All 11 EDMs are Sodick products. These also greatly contribute to furthering the company’s automation efforts.

The company was initially founded in 1960 as Inagaki Iron Works by the uncle of the current President Tetsuya Inagaki, who now serves as the fourth-generation president. Since its founding, the company has focused on cold forging molds for leading automotive parts manufacturers, while also providing a broad range of molds for die casting, pressing, and injection molding.

The adoption of advanced 5-axis machining capabilities in 2008, combined with direct customer input, led to the company’s expansion into drivetrain prototyping in 2010, including parts such as bevel gears and constant velocity joints. In 2018, in response to an accelerating trend in the automotive industry toward electrification, the company began fulfilling orders for copper coil molds used for electric vehicle drive modules. More recently, the company has begun manufacturing separator molds for fuel cell vehicles.

Simultaneously, the company is applying its decades of expertise in high-precision and micromachining technologies to expand into new industries outside the automotive field. Of particular focus is the medical field. With high-precision processing technologies for difficult-to-cut materials including SUS630, Ti-6Al-4V titanium, Inconel, and Hastelloy, the company has maintained active PR initiatives toward the healthcare sector. As a result, the company has expanded its manufacturing portfolio to encompass molds for surgical scalpels and microneedles. The company is also expanding into the aerospace industry, leveraging its specialized machining technologies for hard-to-cut materials.

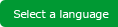

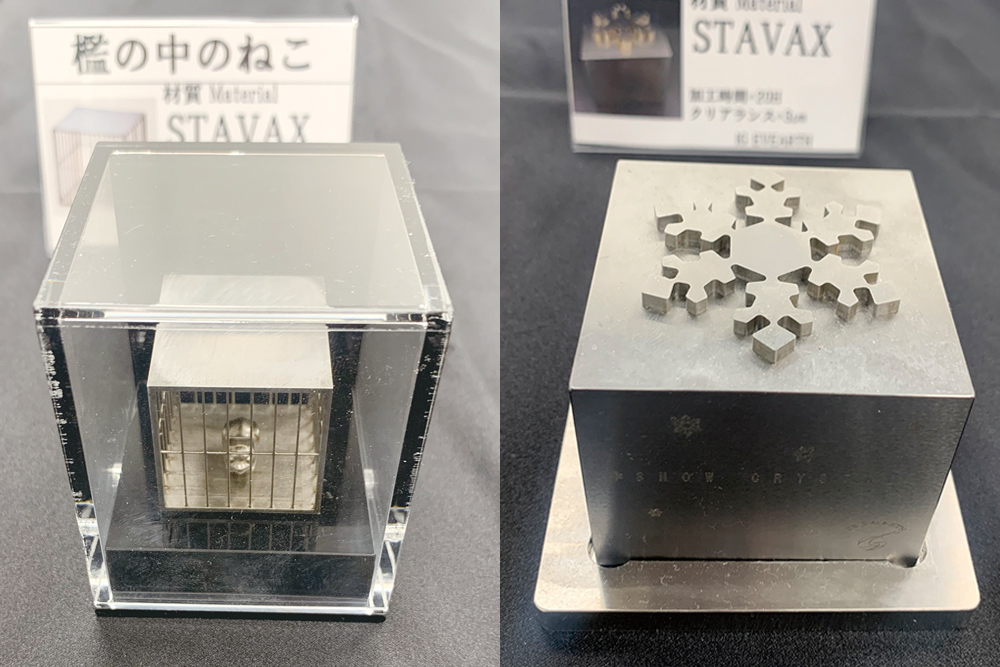

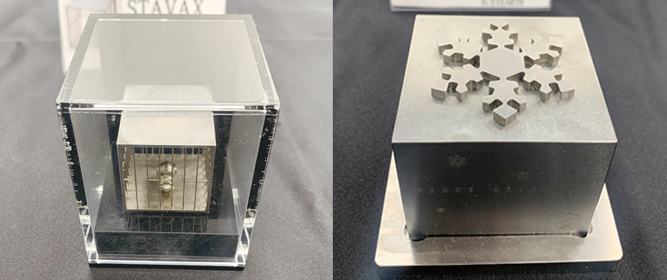

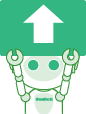

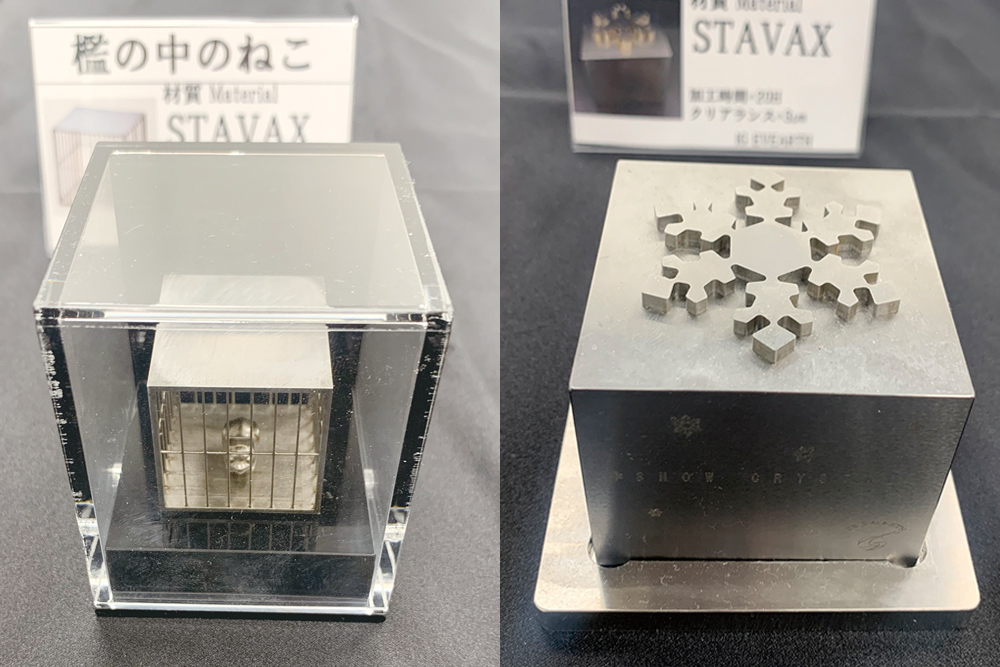

A key driver behind the company’s successful entry into diverse industries has been its dedicated, high-caliber internal R&D team. With a commitment to fostering creativity and advanced machining skills through a playful mindset, the R&D team has developed many innovative products designed to captivate and surprise. Among the company’s distinctive products on show include a scale model of the Burj Khalifa produced with a simultaneous 5-axis machining center, and a ‘Cat in a Cage’, fabricated with a die-sinker EDM. These works have been exhibited at prominent industry events such as Mechatronics Technology Japan (MECT) and the Japan International Machine Tool Fair (JIMTOF). These promotional products demonstrate the company’s advanced technical capabilities, and have garnered considerable interest from exhibition attendees, paving the way for its entry into the medical sector and other fields.

The ‘Cat in a Cage (left)’ and ‘Snowflake Crystal (right)’ created by the R&D team using Sodick EDMs.

The ‘Cat in a Cage (left)’ and ‘Snowflake Crystal (right)’ created by the R&D team using Sodick EDMs.

Showcasing unique, precision-crafted works at major industry exhibitions.

Establishment of a New Smart Factory in 2023

The company’s production hub consists of three facilities in Kariya City, its Headquarters Plant, the Hongo Plant, and the Otsuzaki Plant. The new Headquarters Plant was built in May 2023 following a capital investment of over one billion yen. The new plant serves as a tangible realization of President Inagaki’s forward-looking vision for the company’s future development.

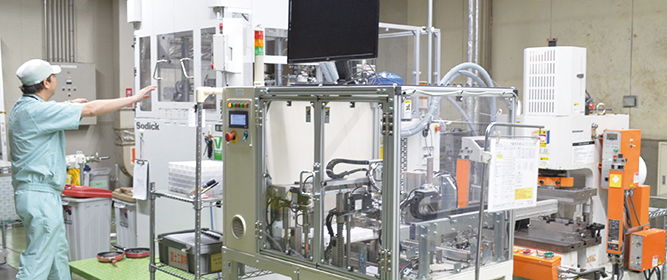

To advance its vision of a smart factory, the Headquarters Plant is spearheading initiatives in DX and automation aimed at the efficient production of high-precision molds and technically demanding prototypes. The workshop on the first floor is set to maintain a constant temperature, and houses three simultaneous 5-axis machining centers, each equipped with a pallet handling system rarely seen in the world of manufacturing. This flexible production system supports high-precision machining of various workpieces, from molds to prototypes, regardless of type. What once took four to five processes on a conventional 3-axis machining center can now be completed in a single process. “This line operates unattended on weekday nights and weekends. Through sophisticated automation and process integration, we’ve achieved a production style that refines high-mix, low-volume into what we call ‘high-mix, single-piece’ manufacturing”, remarks President Inagaki.

All machining processes are visualized using IG-BASE II, a proprietary production management platform. With a comprehensive in-house database of over 80,000 machined parts, the system supports progress tracking and tool management, while also integrating drawing traceability and quality assurance safeguards against defect repetition. Real-time data on machine load and operational status is displayed on large monitors installed at key process points in each plant, helping maintain a monthly output of 3,500 to 4,000 components.

While the new plant was partly conceived as a business continuity planning (BCP) measure to mitigate operational risks from events such as earthquakes and tsunamis affecting the other two plants, the initiative is fundamentally driven by corporate branding efforts focused on talent acquisition and retention. “A key consideration was put on establishing an environment that would empower women in the workplace,” continues President Inagaki. This philosophy is reflected in the design elements such as hotel-inspired restrooms and dining areas, alongside aqua blue flooring in the machining area that symbolizes a serene lakeside environment. The company’s rebranding from Inagaki Iron Works to IG EVEARTH in 2020 was also part of a broader effort to revitalize its corporate image to attract younger talent. This is seen in the large number of young employees and women working on the plant floor. With new graduate hiring on a steady upswing, including the recent addition of a female recruit this spring, President Inagaki expresses confidence in the impact of the company’s corporate branding efforts.

Eleven EDMs All Bearing the Sodick Brand

The company has implemented Sodick’s EDMs as a trusted cornerstone in its electrical discharge machining operations.

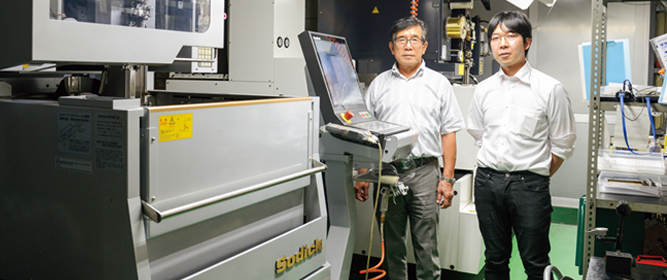

The company currently operates a lineup of 11 EDM, eight wire-cut EDMs, highlighted by the AL400P “i Groove + Edition”, two die-sinker EDMs, including the AG60L, and one K3HS machine, a small-hole drilling EDM. The company first encountered Sodick’s EDMs some 30 years ago. The company first introduced the A50R, a die-sinker EDM. Masato Yoshino, Executive Director and Deputy Head of Manufacturing, reflects on those early days: “Although we used machines from other brands then, our decision to adopt Sodick was driven by its superior machining precision and relatively lower cost”.

After implementing the A50R the company has not looked back, consistently adopting Sodick’s EDMs ever since. This stems from their firsthand experience with the advanced functionality provided by Sodick’s lineup of products, which align perfectly with the company’s pursuit of high-precision mold processing.

One example of this is the “importance of the temperature control system,” something that Yuya Izu, Plant Manager at the Otsuzaki Plant, highlights with regard to the three AL400P units installed at the Headquarters Plant. With its proprietary thermal displacement compensation system, 'TH COM’, Sodick utilizes sensors throughout the machine for temperature detection, and uses this data to apply thermal displacement compensation for sustained machining accuracy. Plant Manager Izu is full of praise for the system, stating “The impact is substantial, even if temperatures shift from morning to night, machining accuracy remains virtually unaffected”.

Plant Manager Izu also underscores the importance of Sodick’s high-speed automatic wire threader, 'FJ-AWT’, which ensures uninterrupted machining by automatically re-threading the wire in the event of breakage, and goes on to call it “absolutely essential for automation”. “Even in the rare event of a wire break while operating at night, the system re-threads the wire with a near-100% success rate. In the past, wire breakage would force us to dial down machining parameters like speed. With this feature, we can now operate at the upper limits of machining capacity with confidence. The system’s proven reliability ensures operators can run it with confidence and peace of mind”.

President Inagaki also praises the ‘AG60L’ linear motor drive high-speed die-sinker EDM for its minimal electrode wear. Naturally by minimizing electrode wear, the system streamlines operations and reduces overall production costs. “Sodick’s EDMs have a well-earned reputation for low electrode wear”, says President Inagaki.

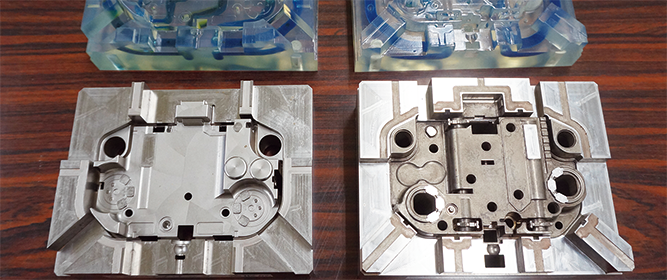

In pursuit of greater mold consistency and cost efficiency, the company is advancing process integration efforts, moving from electrical discharge machining to direct machining. However, the belief that EDMs are pivotal to mold production remains unchanged. “Particularly for features such as deep ribs and undercuts, which are inaccessible to standard cutting tools, conventional cutting processes are inadequate”, continues President Inagaki. Additionally, many clients that have long produced components with EDM often prefer to maintain existing machining methods, requesting work be performed using EDM. “Even as molds become increasingly complex, we do not see EDM diminishing in importance”, states President Inagaki.

Three AL400P units line the floor of the Headquarters Plant. The effectiveness of the temperature regulation system and the high-speed automatic wire threader has been validated in daily operations.

Three AL400P units line the floor of the Headquarters Plant. The effectiveness of the temperature regulation system and the high-speed automatic wire threader has been validated in daily operations.

For High-precision Machining, the Company Opts for the Genuine Consumables

Confidence in Sodick products extends to consumables, such as wire electrodes. “Currently, around 70 to 80% of the consumables used in EDMs are genuine Sodick products”, says Plant Manager Izu. The key factor that the company looks for when selecting consumables is performance. Even if other manufacturer’s products are available at a lower price, “If the performance isn’t there, we can’t use it”, Plant Manager Izu continues.

The company predominantly uses Sodick’s wire electrode, the ‘Hayabusa EX wire’ in the AL400P. Designed to surpass its predecessor, this wire electrode delivers enhanced precision and processing speed, featuring improved tensile strength and straightness, which also enhances connection reliability of the previously mentioned automatic wire threader . “We believe that superior quality and advanced functionality translate directly into faster and more accurate processing. In addition to faster processing, the surface finish quality is exceptionally clean compared to competing solutions”, continues Plant Manager Izu.

The company is flexible in opting for genuine and third-party EDM consumables based on the operational requirements at hand. For instance, pipe electrodes used in the K3HS small-hole drilling EDM are often found to be bent when sourced from other manufacturers. “In that regard, Sodick’s pipe electrodes are noted for their superior straightness”, says Plant Manager Izu. Third-party electrodes are used for relatively low-precision applications, such as start-hole drilling for wire-cut EDM. However, for gas vent holes in molds with tooth-shaped profiles, “There are areas where electrodes must pass through narrow gaps between the teeth, requiring a high degree of precision”, says Plant Manager Izu. This is where genuine pipe electrodes are employed. In this way, the company strategically balances cost efficiency while guaranteeing machining accuracy by tailoring the use of consumables based on the level of accuracy required.

Sodick’s pipe electrodes used in the K3HS small-hole drilling EDM are noted for their superior straightness.

Sodick’s pipe electrodes used in the K3HS small-hole drilling EDM are noted for their superior straightness.

Machine Selection With a Focus on Automation

When it comes to selecting equipment, President Inagaki emphasizes the importance of determining whether the equipment can genuinely meet the machining requirements of the intended workpiece. “While the machine’s performance capabilities are no doubt a key consideration, the question as to whether a piece of machinery can actually build what we are looking to make is another question entirely. Identifying whether or not this is the case is critical”, explains President Inagaki. To ensure the most reliable assessment, “We share part drawings with machine tool manufacturers and request trial production of actual workpieces”, says Director Yoshino.

Another key factor in machine selection is the contribution it makes to the company's ongoing efforts toward automation. “We are particularly focused on machinery capable of supporting our automation efforts to a degree. This comes down to how it is becoming increasingly important to be able to perform machining operations after hours, or during weekends without workers present in order to maintain manufacturing efficiency”, explains Director Yoshino. Plant Manager Izu is of the same opinion. “High precision and fast processing capabilities are regarded as baseline requirements when evaluating machinery. Additionally, we consider how machinery can be integrated with robotics to enable automated setups”.

President Inagaki outlines two key challenges that will shape the company’s future initiatives moving forward. The first involves the pursuit of next-level automation by integrating large 5-axis machining centers with multi-pallet setups. “There is still available space within the Headquarters Plant, and installing even larger machining centers than the current 5-axis machining centers would allow us to cater to demands beyond what our competitors are capable of. Our goal is to achieve high value-added, profit-generating machining processes that improve efficiency and reduce labor costs”, says President Inagaki.

The other area of focus involves enhancing the company’s well-established micromachining technologies. While the company currently houses two micromachining machines, plans to expand this capability to pursue applications not only in the medical field, but also in the broader field of electronic components, such as micro-lens production. “This would require us to invest in additional micromachining machines. One of these micromachining machines that would come into consideration is Sodick’s UX series (linear motor drive machining center)”, states President Inagaki.

Amid a challenging domestic environment for mold manufacturers, IG EVEARTH stands out by making bold investments, such as the new factory, and by advancing both DX and automation as it explores growth in new markets. As a company that embodies the next generation in mold manufacturing, IG EVEARTH shows no signs of slowing its pace of innovation.

Young employees in action at the Otsuzaki Plant, with a row of EDMs lining the plant floor.

Young employees in action at the Otsuzaki Plant, with a row of EDMs lining the plant floor.

Representative Director and President

Tetsuya Inagaki

IG EVEARTH CO., LTD.

- Address

- 104-14 Haidashi, Hajodo-cho, Kariya-shi, Aichi 448-0804 Japan

- Phone

- +81-566-21-3287

- Representative

- Representative Director and President Tetsuya Inagaki

- Established

- 1960

- Business activities

-

- Design and manufacturing of molds for automotive parts

- Manufacturing of components for prototype development

- Manufacturing of copper coil molds for EV drive modules

- Manufacturing of components for powder processing equipment

- Manufacturing of components for vacuum pumps

- Manufacturing of molds for medical devices

- URL

- https://ig-e.co.jp/