- Could each of you please tell me specifically about your responsibilities and how many years you have been in Thailand?

-

Sazaki I have been in Thailand for 11 years now. I am an assistant manager in assembly, which involves working with 250 members of our Thai workforce in operations that include assembly of around 20 EDM models, along with carrying out post-assembly adjustments and machining tests.Kameoka Right now my main focus is design of wire-cut EDMs, but I also handle a wide range of other duties beginning with product development as well as work involving production technology. I have been in Thailand for six years, and was at the Fukui Plant for two and a half years before that.Goto I have been in Thailand for two and a half years. I am in sales, mainly in charge of Japanese companies in Thailand and Vietnam, and my work also involves developing the sales force in Vietnam and planning for trade shows and other events.

Factory VisitSodick Thailand Plants

Ensuring worldwide customer satisfaction.

The culture of Thailand combined with Japan’s Art of Monodzukuri (techniques for creating things).

We set off from Sodick Japan to visit the two factories in Thailand and interviewed three Japanese Sodick employees who are working with more than 1,000 local employees from Thailand while actively helping to underpin worldwide monodzukuri craftsmanship. I asked them about what it is about their jobs that they find rewarding, their commitment, and experiences they have had working in Thailand!

Assistant Manager Career motto Stay upbeat and keep a positive attitude.

Perform your work with care and give it your all. Sodick summed up in a few words A company that supports the monodzukuri approach worldwide

When we returned to the factory floor for the photo session, the atmosphere there immediately brightened and it was obvious that he is popular with many employees and has earned their trust.

Department Engineer Career motto Take initiative wherever possible. Sodick summed up in a few words Satisfies customer needs in the spirit of “Create, Implement and Overcome Difficulties” embraced in the Sodick corporate motto.

He gave straightforward answers when asked about his job, and came across as friendly and confident.

Assistant Manager Career motto Be true to our customers and the company by being true to yourself. Always be on the lookout for new information that can facilitate such aims. Sodick summed up in a few words A fascinating company that belies expectations in a positive way

In our interview, he clearly communicated the appeal of the Thailand Plants from both an insider’s and outsider’s perspective.

- How did you feel when you decided to transfer to the factory in Thailand?

-

Sazaki

At the time I was fairly confident in my ability to perform the work because I had already been handling adjustments and inspections for five years at the Fukui Plant in Japan. I had expressed the vague notion that I wanted to learn more about our products and gain more extensive experience. So, right about that time when I was looking to take the next step in my career the possibility of my being assigned to the Thailand Plants emerged.

Sazaki

At the time I was fairly confident in my ability to perform the work because I had already been handling adjustments and inspections for five years at the Fukui Plant in Japan. I had expressed the vague notion that I wanted to learn more about our products and gain more extensive experience. So, right about that time when I was looking to take the next step in my career the possibility of my being assigned to the Thailand Plants emerged.

I remember that I was determined to accept the appointment and was ready for the challenge, particularly because it was by no means an unexpected development given the factories Sodick operates in Thailand and other overseas locations.Kameoka Actually, I was unofficially informed of the assignment right after I got married. At the time, my wife and I had been planning to have a child, so honestly speaking I was anxious about the move because it didn’t seem like a good time for us. Still, I felt that there would be a lot of advantages to taking the opportunity of overseeing employees at the young age of 26, and in trying my hand at being a manager. So, despite my worries, I came here determined that I would gain immeasurable experience in Thailand.

- What are you most proud of with respect to the Thailand Plants?

-

Goto

There are very few factories in the world that can handle everything at a single facility in terms of printed circuit boards and sheet metal, and processes involving machining and assembly.

Goto

There are very few factories in the world that can handle everything at a single facility in terms of printed circuit boards and sheet metal, and processes involving machining and assembly.

Yet despite the facilities’ wide range of operations, we are still able to ensure sound management and controls. I find that impressive. This gives us significant advantages from a sales standpoint, and customers who come to tour the Thailand Plants often express how amazed they are regarding our extensive operations.

- What is something you focus on throughout the course of day-to-day operations?

-

Kameoka

Obviously we need to develop products that are geared toward market needs, so I think it is crucial that we achieve zero defects in the products we deliver.

To that end, while my job involves drafting product and component drawings, on top of that I also go straight to the shop floor where manufacturing and assembly is performed to actually see with my own eyes what goes on there.

While this means that there are times when production line workers tell me directly that our designs are difficult to implement, taking this approach has actually helped ensure that we come up with feasible manufacturing processes and avoid situations where designs cause defective output.

Sazaki I always try to achieve greater precision than that listed in the specifications by repeatedly measuring assemblies, then reassembling them when necessary, until I am satisfied.

Kameoka

Obviously we need to develop products that are geared toward market needs, so I think it is crucial that we achieve zero defects in the products we deliver.

To that end, while my job involves drafting product and component drawings, on top of that I also go straight to the shop floor where manufacturing and assembly is performed to actually see with my own eyes what goes on there.

While this means that there are times when production line workers tell me directly that our designs are difficult to implement, taking this approach has actually helped ensure that we come up with feasible manufacturing processes and avoid situations where designs cause defective output.

Sazaki I always try to achieve greater precision than that listed in the specifications by repeatedly measuring assemblies, then reassembling them when necessary, until I am satisfied.

Also, I try to make sure that final inspections are performed in operating environments that resemble those of our customers as closely as possible.

- Is there anything that you try to keep in mind when communicating with Thai members of the workforce?

-

Sazaki

In the factories, we have to set specific targets in terms of the number of units that must be produced by certain points in time, and as factory manager I sometimes feel tempted to just tell the employees what to do. However, I have to remember to keep that kind of top-down approach to a minimum, and instead elicit opinions of our Thai staff members in that regard.

To that end, it is important that I create a workplace environment that remains conducive to open communication, particularly because I can't possibly have a full understanding of the work performed by each and every one of my 250 employees.

Goto In the course of our day-to-day operations, I make a concerted effort to speak with our Thai workforce in their language, to respect their culture, and to communicate eye to eye. This helps avoid situations where progress is halted or we head in the wrong direction just because we failed to properly verify details.

Sazaki

In the factories, we have to set specific targets in terms of the number of units that must be produced by certain points in time, and as factory manager I sometimes feel tempted to just tell the employees what to do. However, I have to remember to keep that kind of top-down approach to a minimum, and instead elicit opinions of our Thai staff members in that regard.

To that end, it is important that I create a workplace environment that remains conducive to open communication, particularly because I can't possibly have a full understanding of the work performed by each and every one of my 250 employees.

Goto In the course of our day-to-day operations, I make a concerted effort to speak with our Thai workforce in their language, to respect their culture, and to communicate eye to eye. This helps avoid situations where progress is halted or we head in the wrong direction just because we failed to properly verify details.

Also, I don't have many opportunities to speak with the factory staff because I am often out of the office. So, I make a point of always approaching the different groups of employees and pouring drinks for all of them when we have year-end parties or other gatherings where everyone comes together for drinks and conversation.

- What do you find grateful about working with members of the Thai workforce?

-

Sazaki

I find that people in Thailand tend to show considerable respect toward those that are older and those with seniority.

That part of Thai culture is an advantage when it comes to the workplace environment.

For instance, they tend to respectfully listen to instructions from their supervisors and senior colleagues, which enables them to learn tasks quickly, and they also tend to take a flexible approach in resolving issues when there are problems or operational irregularities.

Still, even now I sometimes feel somewhat bashful when people greet me in the customary manner with the palms of their hands together in a prayer-like gesture.

Sazaki

I find that people in Thailand tend to show considerable respect toward those that are older and those with seniority.

That part of Thai culture is an advantage when it comes to the workplace environment.

For instance, they tend to respectfully listen to instructions from their supervisors and senior colleagues, which enables them to learn tasks quickly, and they also tend to take a flexible approach in resolving issues when there are problems or operational irregularities.

Still, even now I sometimes feel somewhat bashful when people greet me in the customary manner with the palms of their hands together in a prayer-like gesture.

- What sorts of strategies do you use at the design stage to help satisfy customer needs?

-

Kameoka

I try to draw out details on what our customers would like from us, both from Sales and Custmer Service dept.

From the perspective of sales, I have them tell me what kind of machine they would like in terms of certain operational capabilities; and from the perspective of servicing, I make a point of eliciting what our client would like in terms of improvements such as with respect to different machine functions.

Kameoka

I try to draw out details on what our customers would like from us, both from Sales and Custmer Service dept.

From the perspective of sales, I have them tell me what kind of machine they would like in terms of certain operational capabilities; and from the perspective of servicing, I make a point of eliciting what our client would like in terms of improvements such as with respect to different machine functions.

Information that I am able to draw out from the standpoint of Sales and Custmer Service dept. acts as crucial initial data that ends up being reflected in product design.

- Could you tell me about a memorable experience you have had during your assignment here?

-

Goto

I would have to say the big flood of 2011.

During that time, I find that the people of Thailand very admirably pulled together for the good of the team.

I must say, I was very impressed by the Thai people.

Goto

I would have to say the big flood of 2011.

During that time, I find that the people of Thailand very admirably pulled together for the good of the team.

I must say, I was very impressed by the Thai people.

At that time, I wasn't able to perform tasks at our factory because I had to be at a customer’s plant. Then the Thai members of our workforce volunteered without hesitation to take on what I couldn't. That was a big help. Everyone helped us literally being covered with mud. I felt the reason we were able to make a swift recovery is precisely because of the way things are handled in Thailand.

- What experiences have you had that make you feel your job is worthwhile?

-

Kameoka I find it very rewarding when a customer gives me positive feedback about our machines. In the factory, I only have access to feedback from employees involved in manufacturing. So, I am always truly thrilled and feel that our hard work and effort has paid off when a customer, upon delivery of a machine or at a trade fair, tells me that a Sodick machine has outstanding capabilities or performs very well, particularly given the reasonable price tag.Goto My involvement in the style of workplace we have at Sodick where we practice high-quality, high-precision craftsmanship makes my job worthwhile. There are many end-products that form an integral part of many people’s lives, such as cell phones, watches, and cameras, which are partially made using Sodick machines. Knowing this makes me realize that we have benefited many people in a small way. I am proud to be a part of that.

- Could you tell me about your goals?

-

Sazaki In response to demands for greater machine precision and shorter times to delivery, we need to build the tactical capabilities of local staff members and spur workforce development. However, I'm acutely aware that this will not be possible unless I first build on my own operational and legal expertise. As such, I really want to actively take on new career challenges.Kameoka Although my work right now mainly consists of wire-cut EDM design, I would really like to become involved in all aspects of die-sinker EDMs and other units manufactured in the Thailand Plants. I would also be interested in working on design of an entire machine.

I aim to take part in job opportunities the enable me to build up wide-ranging expertise.Goto First off, my goals involve achieving sales targets and developing markets. Business in Vietnam is really picking up steam, so I would like to actively pursue opportunities in that market. I spend seven to ten days there every month, and take part in meetings to forge new deals on each of those days. Also, it would be great if I could spend a bit of time engaging in dialog with people there, and working with them in helping to build organizations. I think that work can be a lot of fun. As such, it is my hope that in working with others we can all experience that sense of enjoyment together.

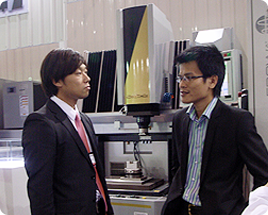

We held our interviews during the Metalex Thailand 2013 trade fair, so our interview crew was able to accompany salesman Hiromiki Goto as he went to the exhibition site.

The Sodick booth stood out given its prominent location nearby the exhibition hall entranceway.

We were quite impressed to see how Mr. Goto dealt with the enthusiastic visitors to the Sodick booth.

He actively takes part in trade fairs in various countries, and we could tell that he is able to gain a clear understanding of the markets in those countries, while linking that knowledge to further product development.