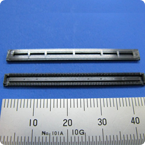

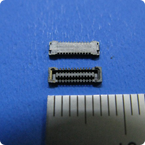

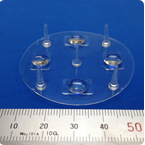

Mother Machines that Create Precision Components that Go from the Kaga Plant to the World

Once the design is completed, the components are purchased and

assembled according to drawings.

When a product is completed,

it goes to final operation testing prior to delivery.

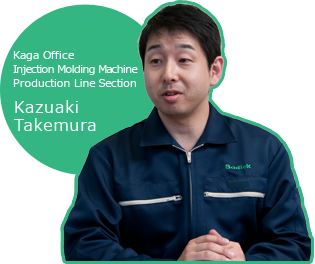

We talked to Mr. Kazuaki Takemura, who is now in his 6th year

carrying out adjustments for the testing of injection molding machines.

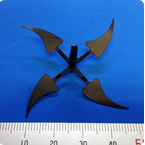

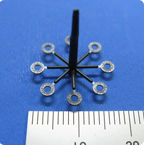

The Sodick injection molding machines use the original Sodick V-LINE® technology for injection (injection plunger) and plasticization (plasticization screw).

By using one part to heat the plastic to a liquid state and another part to inject the melted plastic, the plastic can be measured out to a consistent density, preventing resin backflow and pressure loss during injection.

This minimizes defects and helps to reduce costs.

Sodick supplies mostly vertical and horizontal injection molding machines, delivering products that are tailored to the aims of the customer.