TOPICS

NEWS

- '26.02.19 Company

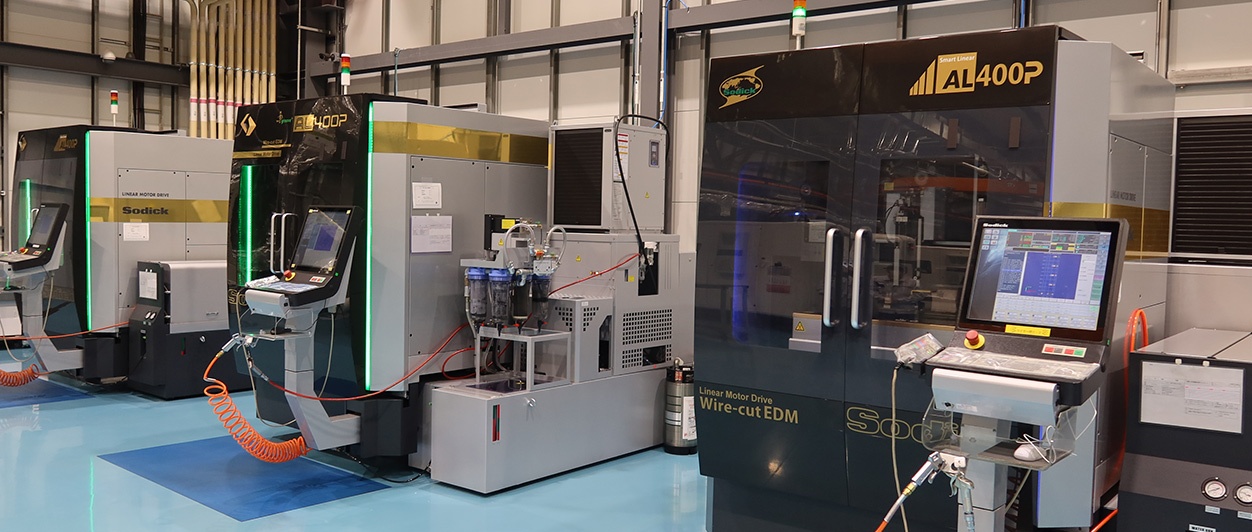

- Updated Sodick Report. This time features the “Nihonseiki Co., LTD.”.

- '25.12.19 Company

- Updated Sodick Report. This time features the “IG EVEARTH CO., LTD.”.

- '25.03.28 Company

- New President Announcement

IR NEWS

- '26.02.20

- Q&A Overview for FY2025 Results Briefing(PDF:201KB)

- '26.02.17

- FY2025 Results Briefing(PDF:2,241KB)

- '26.02.13

- Notice Concerning Acquisition of Treasury Shares(PDF:307KB)

- '26.02.13

- Notice Regarding the 50th Anniversary Commemorative Dividend(PDF:305KB)

- '26.02.13

- Notice Regarding the Formulation of a Medium-Term Management Plan and Change in Shareholder Return Policy(PDF:310KB)

- '26.02.13

- FY2025 Results Briefing - Supplemental Data(PDF:168KB)

- '26.02.13

- Notice Regarding the Differences between Forecast and Actual Consolidated Financial Results for the Fiscal Year Ended December 31, 2025(PDF:317KB)

- '26.02.13

- FY2025 Consolidated Financial Results(PDF:295KB)

- '25.12.08

- Notice Regarding Change of Trade Name of Consolidated Subsidiary(PDF:161KB)

- '25.11.12

- Establishment of a New Company in Germany in Partnership with YAMAZEN CORPORATION(PDF:190KB)