It achieves high speed and quality surface finish by adopting the stable EDMing system "Arc-less 4".

Awards

Main Award at the 61th (2018) Best 10 New Product Awards (Sponsor: Nikkan Kogyo Shimbun)

Awards

Main Award at the 61th (2018) Best 10 New Product Awards (Sponsor: Nikkan Kogyo Shimbun)

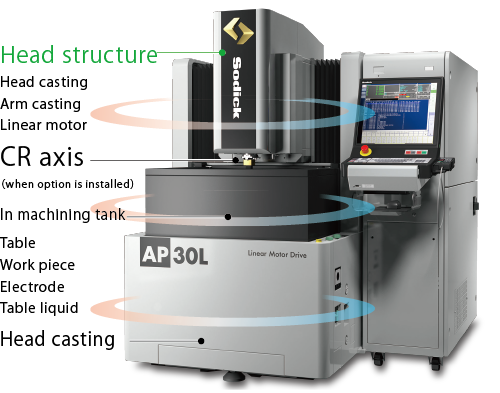

Developed to allow circulation of machining fluid and cooling liquid, and overall temperature control.

Changes in temperature affect extremely high-precision machining.

AP30L collectively manages all the ambient temperature changes and internal heat generation through the overall temperature control.

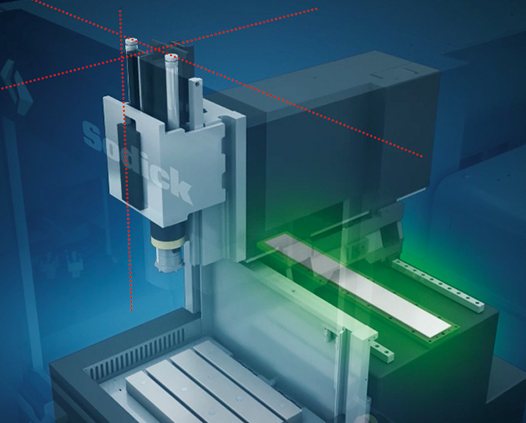

Maintains extremely accurate positioning of ball screw-less for a long period.

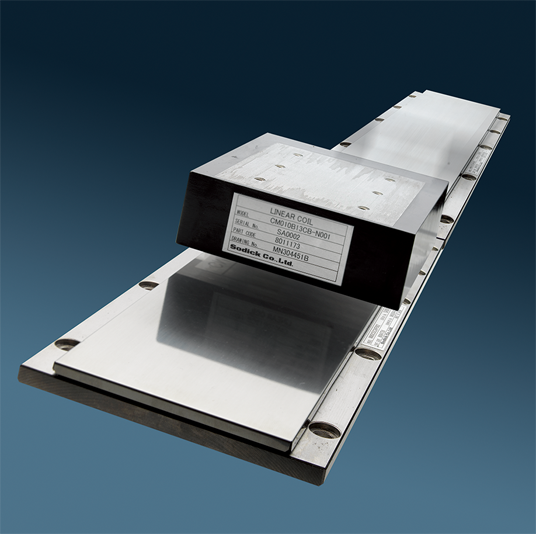

Sodick has installed the linear motor into die-sinker EDM for the first time in the world and has more than 20 years of sales experience. Our linear motor control technology has many excellent features and has received high evaluation from customers all over the world.

With unparalleled technology and ultra lightweight, it shows extremely high performance in high speed jump.

Improves machining speed in all of rough machining, semi-finishing, finishing

Arc-less 4 (discharge stabilized machining system)

Discharge state is maintained steadily, further speeding-up is possible. In addition, it realizes suppression of electrode consumption to the utmost limit, achieves a wide variety of processed surface quality ranging from satin finish to mirror finish, improves the performance of electric discharge machining.

TMM4 circuit (rough machining)

Improves machining speed of rough machining by short-pulse and high-peak current.

TPC4 control (semi-finishing)

Speeds up the semi-finishing machining with narrow gap.

BSN4 circuit (finish)

Improved micro-finishing speed, useful for narrow pitch connectors. New feature on SP Power Supply.

SVC Circuit

High-speed, high-quality surface finishing circuit refined by Sodick through generations.

Artificial Intelligence technologies to maximize the potential of AP30L

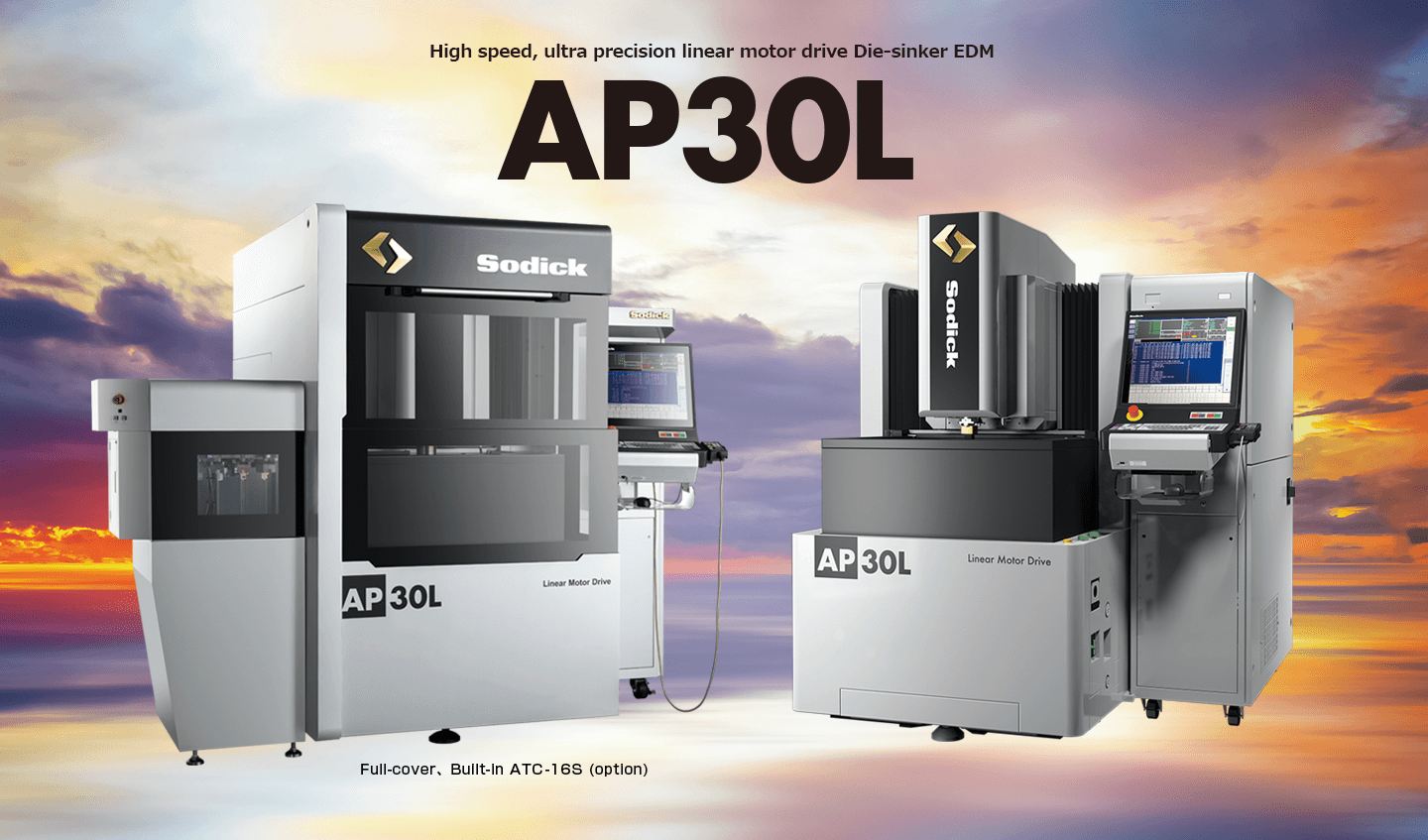

AP30L Full-cover (Option)

The effect of disturbance is minimized by shutting off with outside air, and manpower saving in ultra-precision machining is possible.

*Picture is a built-in ATC-16S (option)

*The power supply of this video is LP4.