Customers who are considering a linear motor

for the first time

Advantages of Linear Motors

Linear motors are said to have superior travel speed and positioning accuracy compared to motors with ball screw construction.

They also have high responsiveness and long-term stability due to less mechanical contact. Sodick's linear motors have a unique cooling structure, and we have accumulated a wealth of technology related to linear motors, including the know-how to design and produce the optimum linear motors for various types of machinery and equipment.

Types of Linear Motors

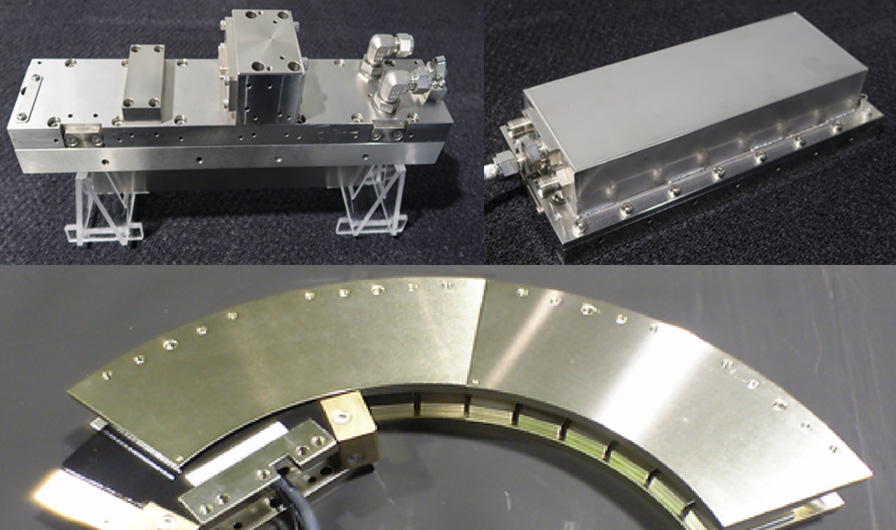

1Linear motor with core

The structure of a coil wound around a core (iron core) can generate a large thrust force. On the other hand, the generation of attraction (cogging) between the magnet plates results in inferior speed stability compared to coreless motors.

Main applications of core-equipped linear motors

- Electrical discharge machines, machining centers

Precision machine tools and various production machines that require large thrust force.

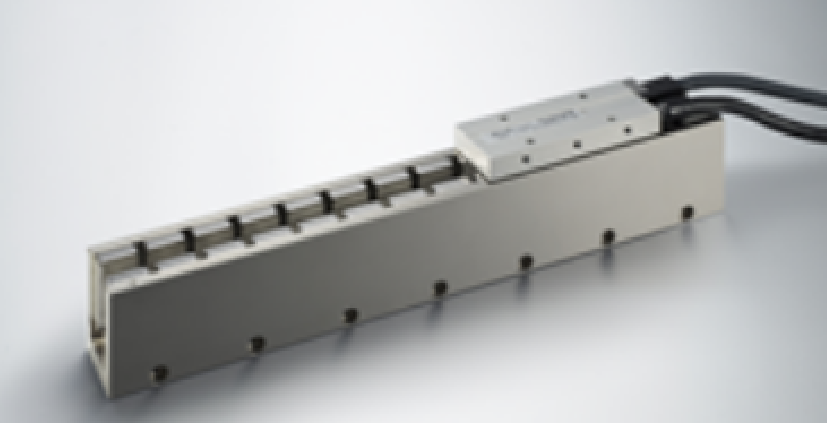

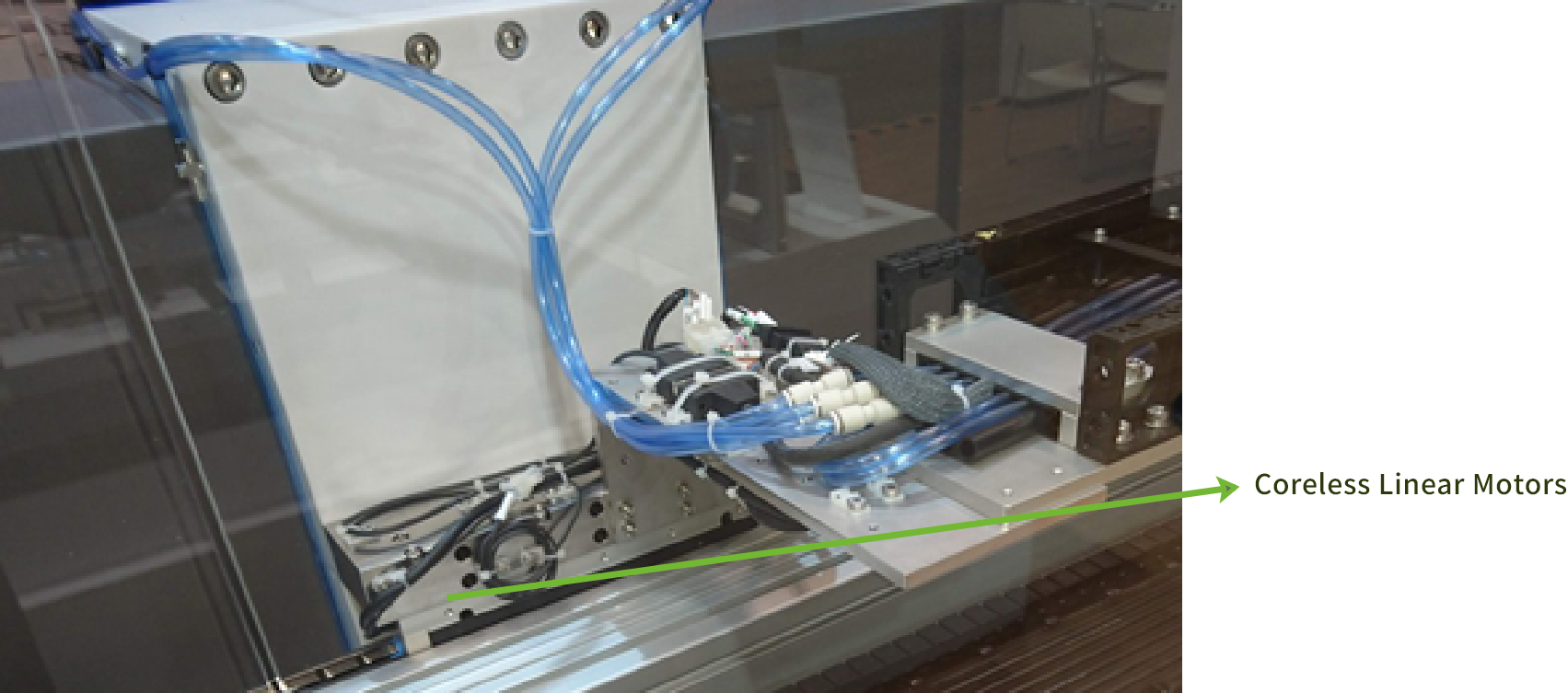

2Coreless Linear Motor

It is characterized by smaller speed fluctuations compared to cored components. As a machine component, it increases rigidity and, in combination with a high-performance servo system, provides excellent control performance.

Main applications of coreless linear motors

- FPD manufacturing equipment, semiconductor manufacturing equipment

- High-precision laser processing machines

Used in precision machine tools and manufacturing equipment requiring high precision.

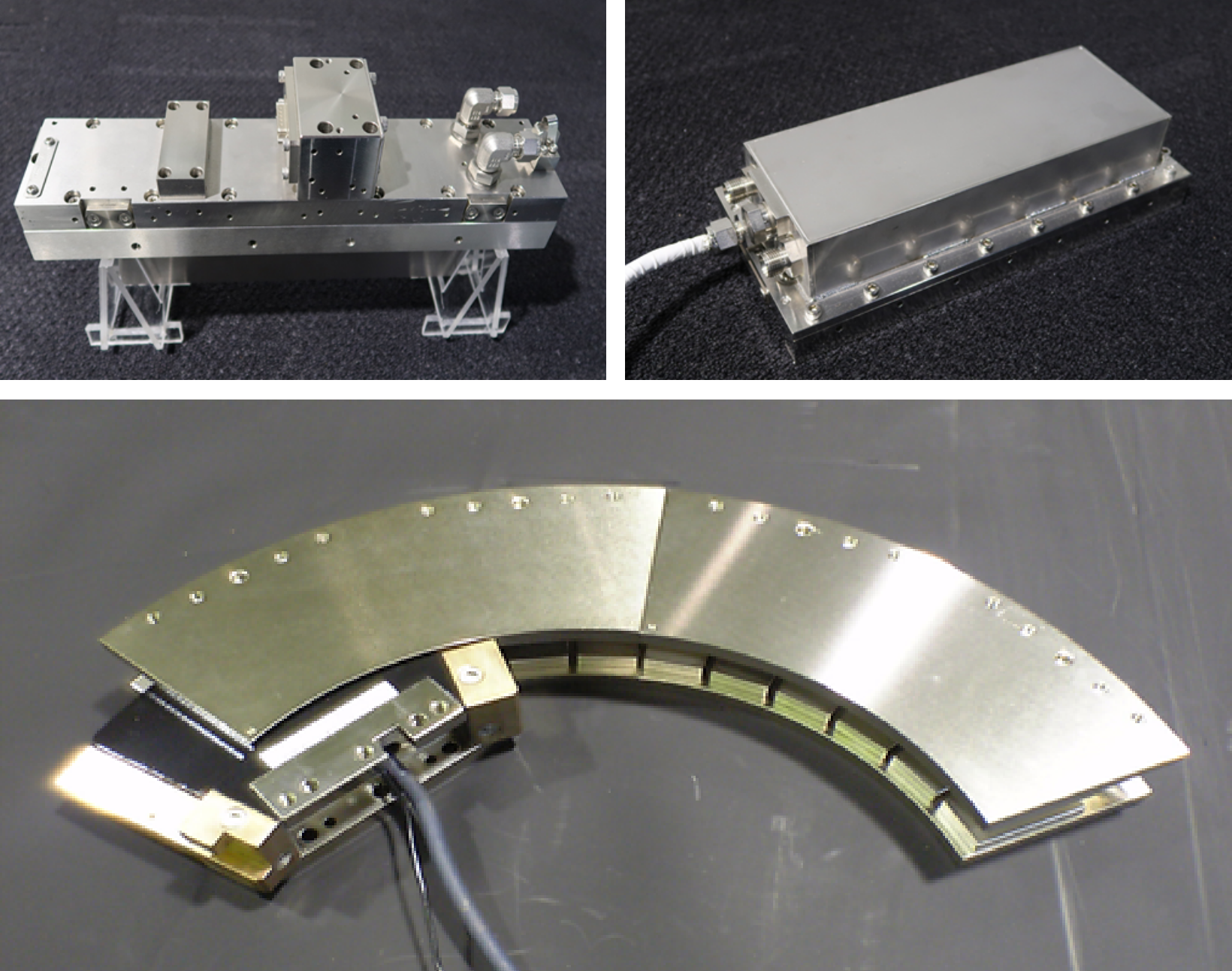

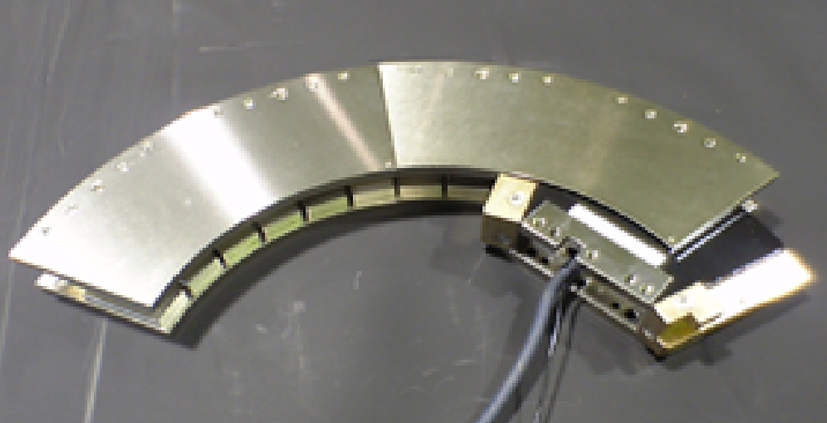

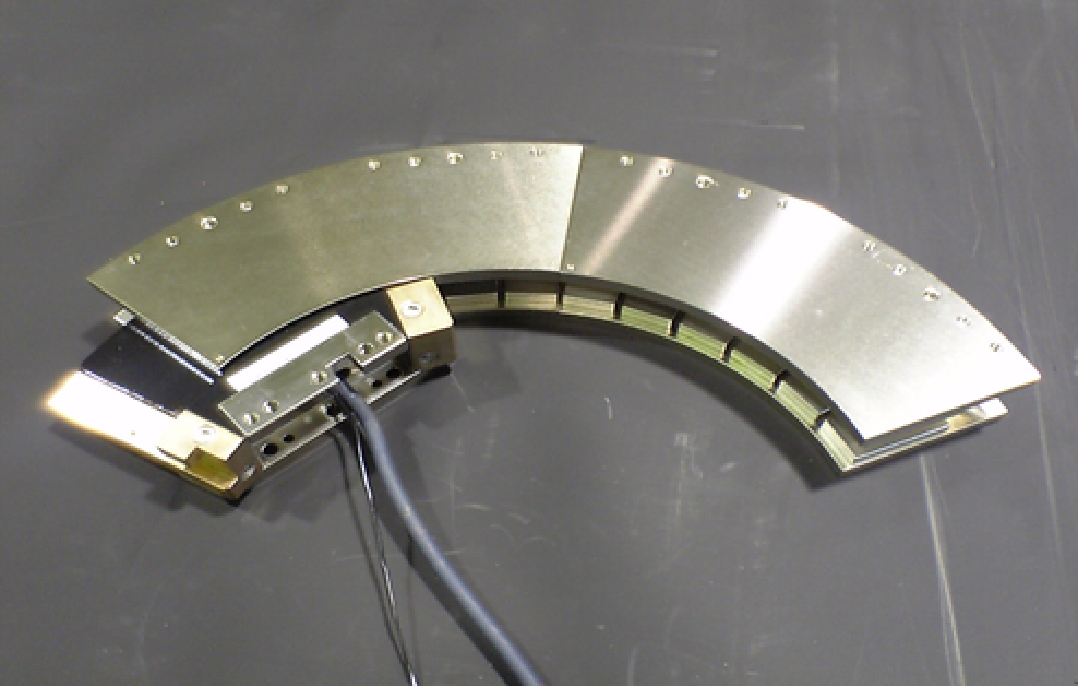

3Arc Linear Motor

Arc-type coreless linear motors capable of rotary motion and micro-angle control.

Main applications of arc linear motors

- Rotary motion and micro-angle control are required.

Industrial machinery, machine tools

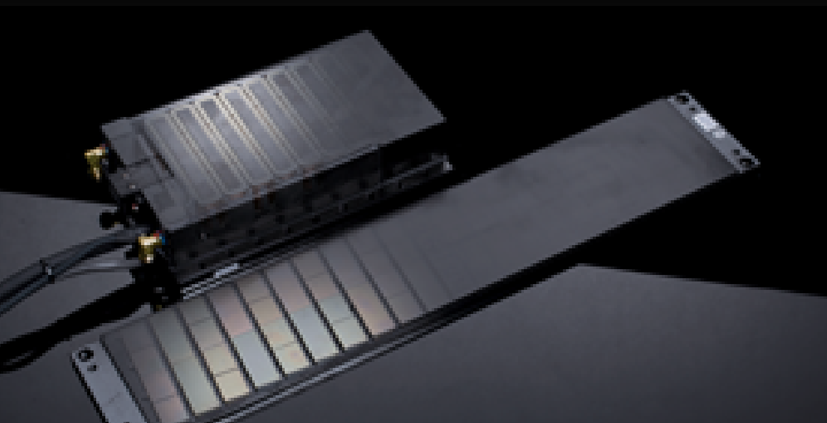

4Vacuum Linear Motor

Linear motors are equipped with a cooling mechanism to suppress outgas emissions, which can be a problem in vacuum environments. Coreless and cored types are available.

Applications of Vacuum Linear Motors

- FPD manufacturing and transport equipment, semiconductor manufacturing equipment, etc. used in a vacuum environment

Products

Sodick's Servo Amplifier

In addition to standard PWM amplifiers, Sodick offers linear amplifiers and high-frequency amplifiers as high response servo amplifiers to achieve nano-level control.

Panasonic AC servo amplifiers are also available for Sodick linear motors, which can be used with a variety of high-level controllers.

Introduction to Motor Drive Amplifiers

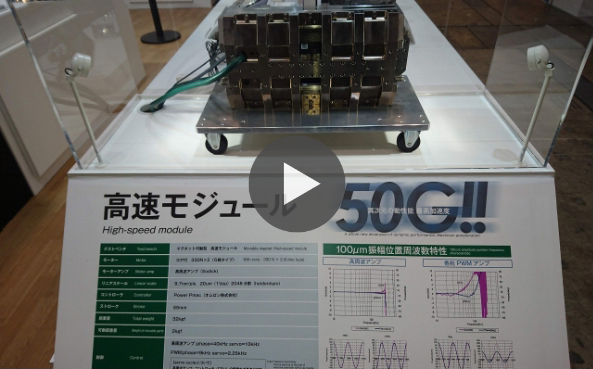

High response servo amplifier

Linear amplifier, high-frequency servo amplifier

We have experience in nano-level control using a combination of Sodick servo amplifiers and OMRON's PMAC.

Pulse command, analog command, RTEX, and EterCAT interfaces can be supported, enabling control by various types of host controllers.

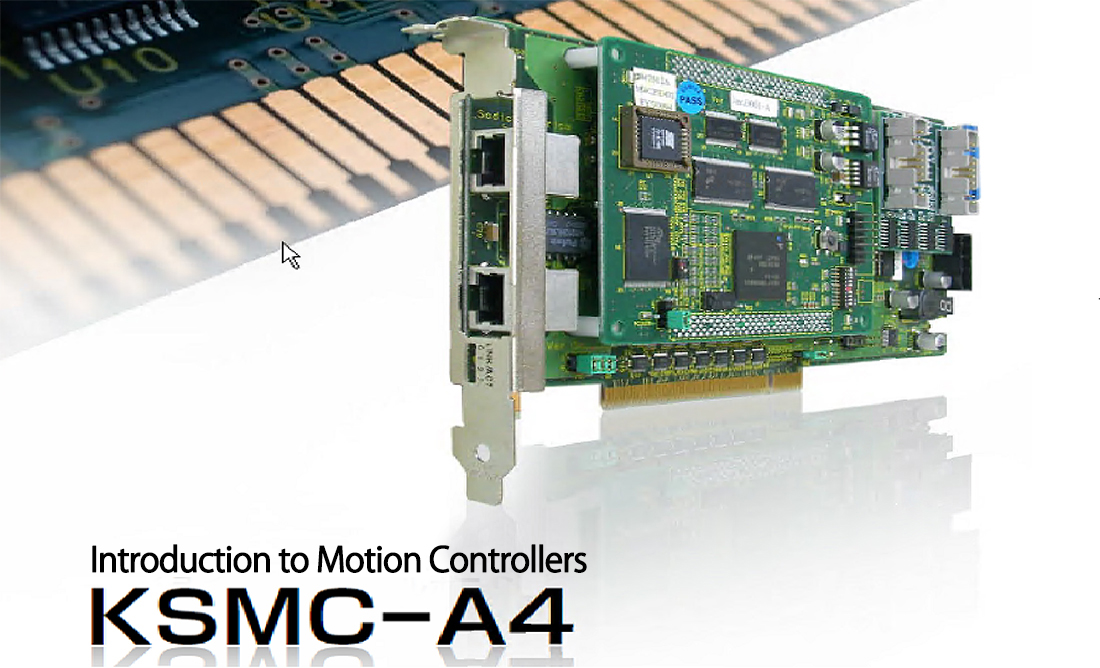

Introduction of Motion Controllers

What is a motion controller?

This device controls multiple servo motors at high speed.

Sodick's motion controller KSMC-A4 is connected to PCl BUS and is compatible with Panasonic's AC servo amplifiers MINAS-A5NL and A6, enabling simultaneous storage of up to 32 axes and 8 axes.

Main applications of the motion controller

- Machine tools and industrial machinery in general

Introduction to Motion Control Board KSMC-A4

Introduction to Sodick Special Motors

Sodick has experience with special motors.

Case Studies

Case Study (1)

Introduction to high-precision systems

Case Study (2)

Introduction to the combination of linear motors

and ceramic components

Linear motor selection and other Q&A

Click to answer questions!

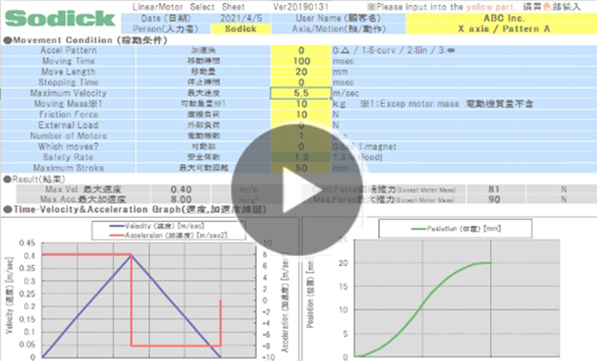

- Q1How can I select a linear motor?

-

From the Sodick website,

go to Products > Motion > Electronic Catalog > Linear Motor Selection Tool

Download the Linear Motor Selection Tool

Motion Electronic Catalog (Japanese)

*To learn how to use the selection tool, please see this video. - Q2What precautions should I take when using a linear motor for the first time?

-

If you use a linear motor,

you will need a linear scale to check the position of the motor.

Since linear motors are vulnerable to disturbances, the placement of the motor and the rigidity of the equipment are important, and the location of the linear scale is also important.

We will be happy to provide advice if needed.

Please feel free to contact us. - Q3What if we want you to check if the motor we selected is correct?

-

If you send us the following documents, our engineers will check them for you.

- Selection results

- Conditions related to kinematic performance (weight of movable objects, maximum speed, acceleration, stroking, etc.)

- Operation pattern (for one cycle)

- Schematic diagram of the device, if available

- Q4What kind of amplifier should I use?

-

It is necessary to use different amplifiers depending on the performance of the equipment to be produced.

- Sodick's amplifiers are available in "PMW amplifier", "High frequency amplifier" and "Linear amplifier".

- PWM amplifier" and "High frequency amplifier" are recommended for high-precision positioning by direct command from a high-level controller.

If you want to avoid noise from the amplifier, "Linear amplifier" is recommended.

- PWM amplifier" and "High frequency amplifier" are recommended for high-precision positioning by direct command from a high-level controller.

- For general-purpose amplifiers, we recommend "*Panasonic amplifiers".

- If you want to control by puzzle row, etc., "Panasonic amplifier" is recommended.

"Panasonic amplifier" = "AC servo amplifier for linear motor drive" manufactured by Panasonic Corporation.

Note!When using Sodick amplifiers, please note that there are restrictions on the upper controller.

- If you want to control by puzzle row, etc., "Panasonic amplifier" is recommended.

Click here for details.

- Sodick's amplifiers are available in "PMW amplifier", "High frequency amplifier" and "Linear amplifier".

- Q5Is it possible to manufacture special motors?

-

Please provide us with your specifications, and our staff will check them for you.

Please feel free to contact us for consultation.Click here for details.

Special Motors

Introduction to high performance servo amplifier

Sodick offers a lineup of two high-performance servo amplifiers for nano-control

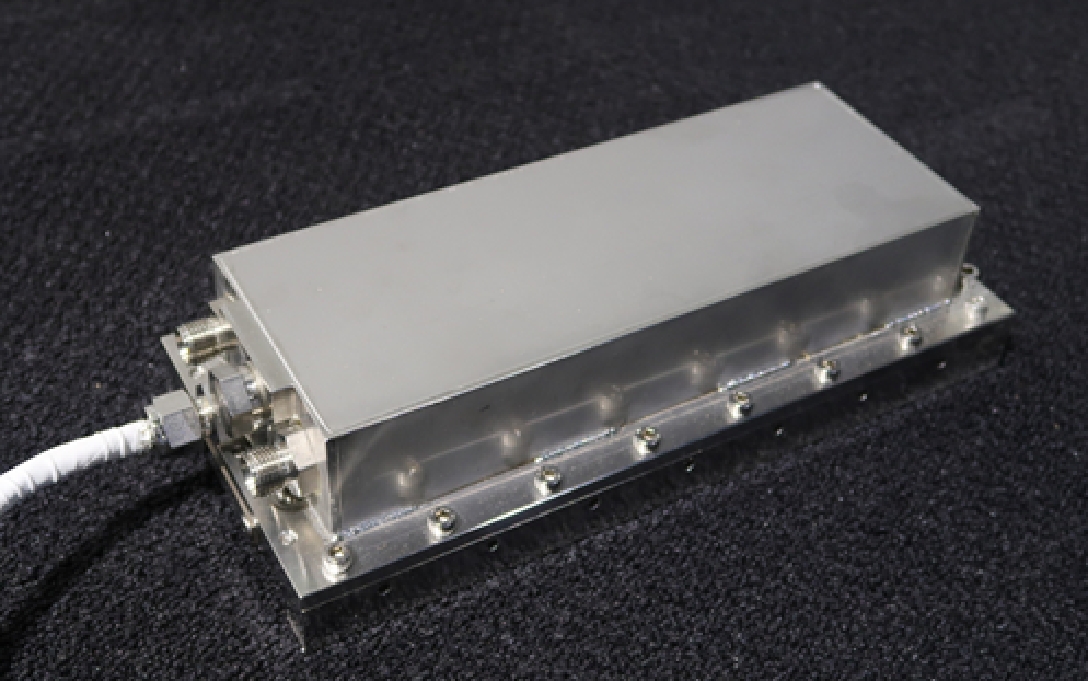

Linear amplifier LNPA10-2

2-Phase Digital Torque

Command type current amplifier

Analog amplifier

Position control

Cycle speed improvement

Wideband

Current control

Features

- Analog current loop real-time control

- Full analog modulation

Minimal zero-crossing distortion

Operates with high linearity over the entire control range - Position control settings can be made at the maximum performance of the motion controller

Not limited by amplifier specifications - High positioning performance can be achieved with a high-resolution positioning system consisting of an air slider

- Supported controllers

SODICK motion controller

Motion controller made by OMRON

Performance Example Positioning Control Characteristics~ Example of performance improvement by replacing a competitor's amplifier with a new one ~

| Equipment | Precision XYZ Stage | Remarks |

| Motor | CA010 x 2 | Catalog standard products |

|---|---|---|

| Amplifier | LNPA10 | |

| Motion controller | PMAC2 | OMRON |

| Position detection resolution | 0.064nm | 0.128um / 2000 division |

| Position control cycle | 16kHz |

*The data listed above do not guarantee the performance of the equipment.

Linear amplifier LNPA10-2 Specifications

| Amplifier Overview | |

|---|---|

| Amplifier type | 2-phase current command type amplifier |

| Current loop function | with |

| Phase control function | without |

| Modulation method | real-time analog |

| Torque command method | 2-phase 18-bit serial current command |

| Applicable motor | 3-phase servo motor |

| Basic Specifications | ||

|---|---|---|

| Continuous output current | 4.5[Arms] Depends on motor electrical constants | |

| Maximum output current | 8[A] Depends on motor electrical constants | |

| Current detection range | 10 [Ao-p] | |

| Structure | Base mount installation | |

| Dimensions[mm] | 260(h) x 95(w) × 319(d) | |

| Weight[kg] | 2.3[kg] | |

| Power supply | Ccontrol circuit Main circuit |

DC±16V 15W each DC±20~250 250W each |

| Operating environment | Operating temperature Operating humidity |

15~30°C 65%RH or less (no condensation |

| Signal | Input signal Output signal |

Amplifier enable signal Current command signal Amplifier fault signal |

| Protection function | Alarm type | Watchdog error, control power failure, Cooling fan stoppage, overheating, main power overvoltage, Main power supply undervoltage, overcurrent |

| Status Indication | LED 7 segment LED |

READY Watchdog error Servo-on, error identification |

| Safety Standards | We are preparing to obtain product safety standards such as European and American standards. | |

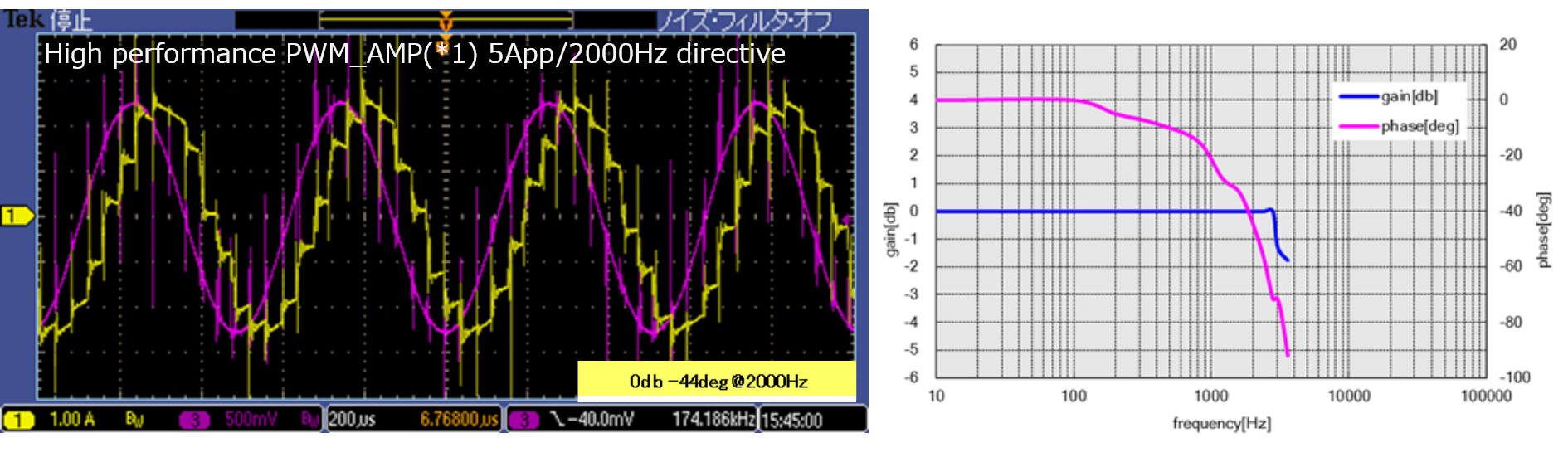

High frequency amplifier SA-1020A

2-Phase Digital Torque

Command type current amplifier

High speed switching amplifier

Position control

Cycle speed improvement

Wideband

Current control

Features

- High speed switching 90 (standard specification) to 160kHz

- Short dead time 0.135μsec

- PWM modulation

- Current loop operating with low zero-crossing distortion and high linearity throughout the control range

- Allows position control settings at maximum motion controller performance

No restrictions on amplifier specifications - Supported controllers

SODICK motion controller

Motion controller made by OMRON

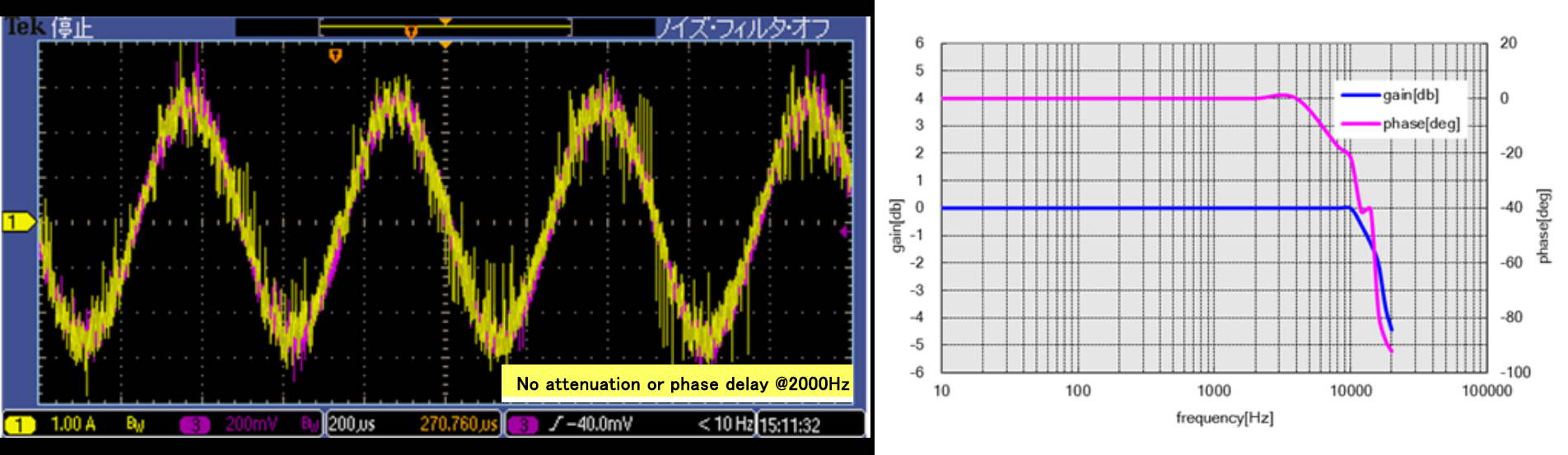

SA-1020A Performance Example

Current F Characteristics 2 vs. Other Companies - High Performance Amplifier

Test load: CB100D (SODICK standard coreless motor)

Resistance between phases: 2.0Ω / Inductance between phases: 1.2mH

High performance PWM_AMP(*1) 5App/2000Hz directive

SA-1020A(*2) 5App/2000Hz

*1 Analog command amplifier

*The data listed above do not guarantee the performance of the equipment.

High Frequency Amplifier SA-1020A Specifications

| Amplifier Overview | |

|---|---|

| Amplifier type | 2-phase current command type amplifier |

| Current loop function | with |

| Phase control function | without |

| Modulation method | PWM modulation |

| Torque command method | 2-phase 18-bit serial current command |

| Applicable motor | 3-phase servo motor |

| Basic Specifications | ||

|---|---|---|

| Continuous output current | 10.0 [A] | |

| Maximum output current | 20.0 [A] | |

| Current detection range | 25.0 [Ao-p] | |

| Structure | Base mount installation | |

| Maximum switching frequency | 160kHz | |

| Dead time | 0.135 [usec] | |

| Dimensions[mm] | 256(h) x 114(w) x 173(d) | |

| Weight[kg] | 3.6 [kg] | |

| Power supply | Ccontrol circuit Main circuit |

Single phase DC24V ±5% 2A Three phase AC100-5% to 200V+5% 50/60Hz |

| Operating environment | Operating temperature Storage temperature Operating humidity Storage Humidity |

10~45°C -20~70°C 90%RH or less (no condensation) |

| Signal | Input signal Output signal |

Amplifier enable signal Current command signal Amplifier fault signal |

| Protection function | Alarm type | Watchdog error, control power failure, Cooling fan stoppage, overheating, main power overvoltage, Main power supply undervoltage, main power supply missing phase, overcurrent, gate error |

| Status Indication | LED 7 segment LED |

READY Watchdog error Servo-on, error identification |

| Safety Standards | Please consult with us about product safety standards such as European standards and American standards. | |

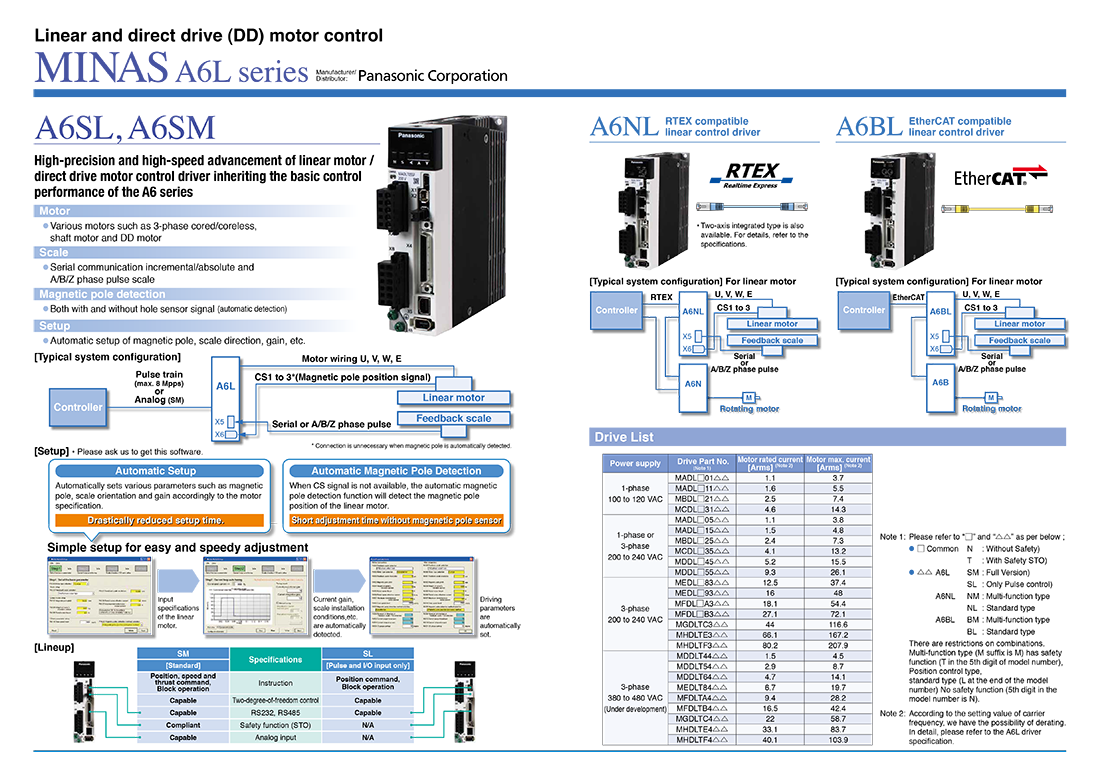

Introduction to AC Servo Amplifier

for Linear Motor Drive of Panasonic Corporation

RTEX, EtherCAT, general-purpose pulse train output,

and analog output drive are available.

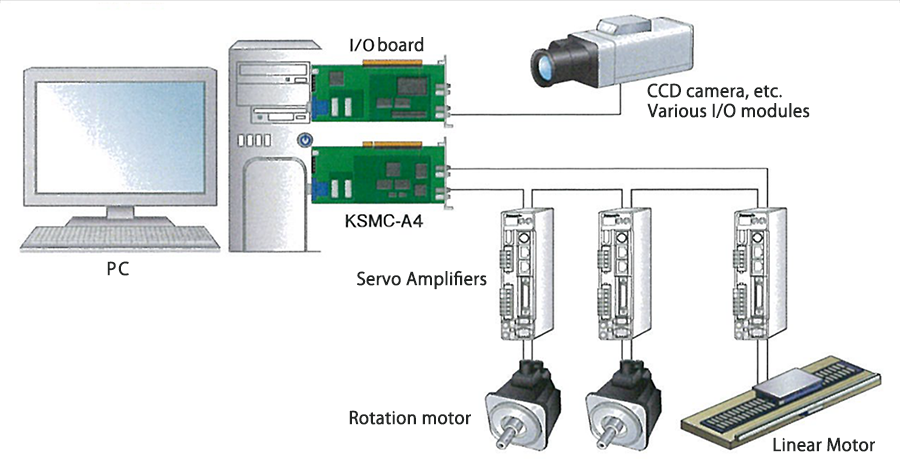

Introduction to Motion Control Board

KSMC-A4

The KSMC-A4 is a motion controller compatible with Panasonic Corporation's RTEX

(Panasonic Realtime ExpressTM) equipped servo amplifier MINAS-A5ⅡNL.

A single KSMC-A4 can control up to 32 axes,

making it ideal for point-to-point applications such as dispensers and die bonders.

The KSMC-A4 can control up to 32 axes, making it suitable for industrial machines that control many axes point to point, such as dispensers and die bonders, as well as CP control (continuous path control).

Example of system configuration

Specifications

Hardware

| CPU | SH4A@400MHz 32bit RISC Processor |

|---|---|

| Number of control axes | Max. 32 axes (Communication cycle: 1 ms) / 8 coordinate systems. |

| Communication Interface | PCI Bus(PC ⇔ KSMC-A4) 100Base - TX Ethernet(KSMC-A4 ⇔ Servo amplifier) |

| Communication speed / Synchronization | 100Mbps Full Duplex / 1ms |

| General-purpose I/O | Input 16 points, Output 16 points |

| Counter Input | A/B phase square wave 1 ch |

| External dimensions | 209mm x 108mm x 27mm |

| Supply voltage | DC5V ±5% (from PCI Bus) |

Software

| Basic control functions | PLC functions, reading and setting of A5IINL parameters, etc., jog, home return, trigger operation. |

|---|---|

| Acceleration/deceleration method | Straight line / S-shape / Trapezoid |

| Interpolation function | Straight line / Circular arc / Spline |

| Correction function | Backlash correction, pitch error correction, flat pitch correction |

| Servo filter | Notch filter (2-stage), disturbance observer |

| System protection function | Excessive position deviation, run-time error, overcurrent, soft limit, hard limit |

| Macro variable | 131072 (0x20000) pieces |

| PLC | Periodic PLC (100 pcs), Sequential PLC (700 pcs) |

| Other | Gathering function. *1 |

*1 Gathering of 16384 (0x4000) units/CH with maximum 16CH is possible.

Introduction to Special Motors

Sodick's Special Motor Performance

Coreless motor for vacuum CA030u

Main specifications

| Item | Unit | Specifications |

| Rated Force | N | Please contact us. |

|---|---|---|

| Maximum force | N | Please contact us. |

| Rated Current | Arms | 6 |

| Maximum Current | Arms | 17 |

| Rated Velocity | m/sec | Please contact us. |

| Maximum Velocity | m/sec | Please contact us. |

| Force constant | N/Arms | 16.8 |

| Attractive Force | N | - |

| Motor Coil Weight | Kg | 9 |

| Proof Pressuer of Cooling Pipe | Mpa | 0.147 |

| Recommended Refrigerant | - | Controlled Water 1L/min |

| Vacuum | Torr/pa | 10-7 / 10-5 |

Motor with core for vacuum applications CE033C11(UHV)

Main specifications

| Item | Unit | Specifications |

| Rated Force | N | Please contact us. |

|---|---|---|

| Maximum force | N | Please contact us. |

| Rated Current | Arms | 15.4 |

| Maximum Current | Arms | 30 |

| Rated Velocity | m/sec | Please contact us. |

| Maximum Velocity | m/sec | Please contact us. |

| Force constant | N/Arms | 35 |

| Attractive Force | N | 1400 |

| Motor Coil Weight | Kg | 10 |

| Proof Pressuer of Cooling Pipe | Mpa | 0.147 |

| Recommended Refrigerant | - | Controlled Water 1L/min |

| Vacuum | Torr/pa | 10-7 / 10-5 |

Coreless arc motor CR050A

Main specifications

| Item | Unit | Specifications | |

| Rated Output | W | 193 | |

|---|---|---|---|

| Rated Torque | Water Cooling Self Cooling |

N・m N・m |

18 10 |

| Maximum Torque | N・m | 74 | |

| Rated Current | Water Cooling Self Cooling |

Arms Arms |

1.5 0.8 |

| Maximum Current | Arms | 6 | |

| Rated RPM | rpm | 100 | |

| Maximumu RPM | rpm | 150 | |

| Torque Constant | N・m/Arms | 12.3 | |

| Motor Coil Weight | Kg | 1.9 | |

| Proof Pressuer of Cooling Pipe | Mpa | 0.147 | |

| Recommended Refrigerant | - | Controlled Water 1L/min | |

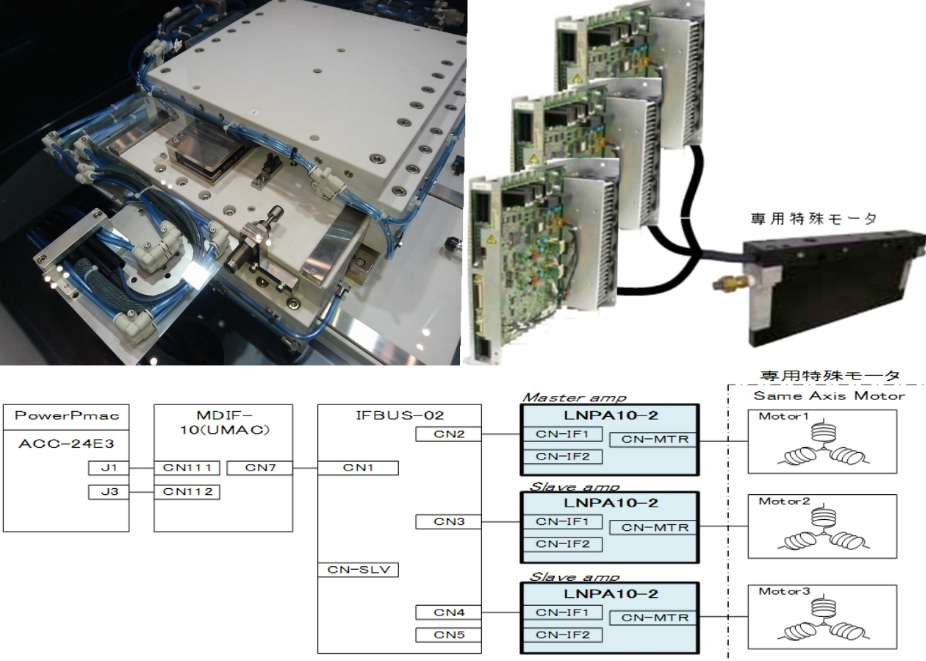

Case Study (1)

Introduction to high performance control system proposed by machine tool manufacturer SodickIntroduction to high performance control system proposed by machine tool manufacturer Sodick

What is the general system?

Feedback control is configured in each motor driver,

and motor drivers are asynchronous to each other.

This configuration is not suitable for devices that require nano-order accuracy,

but is relatively inexpensive and easy to handle.

Proposal of High Precision System

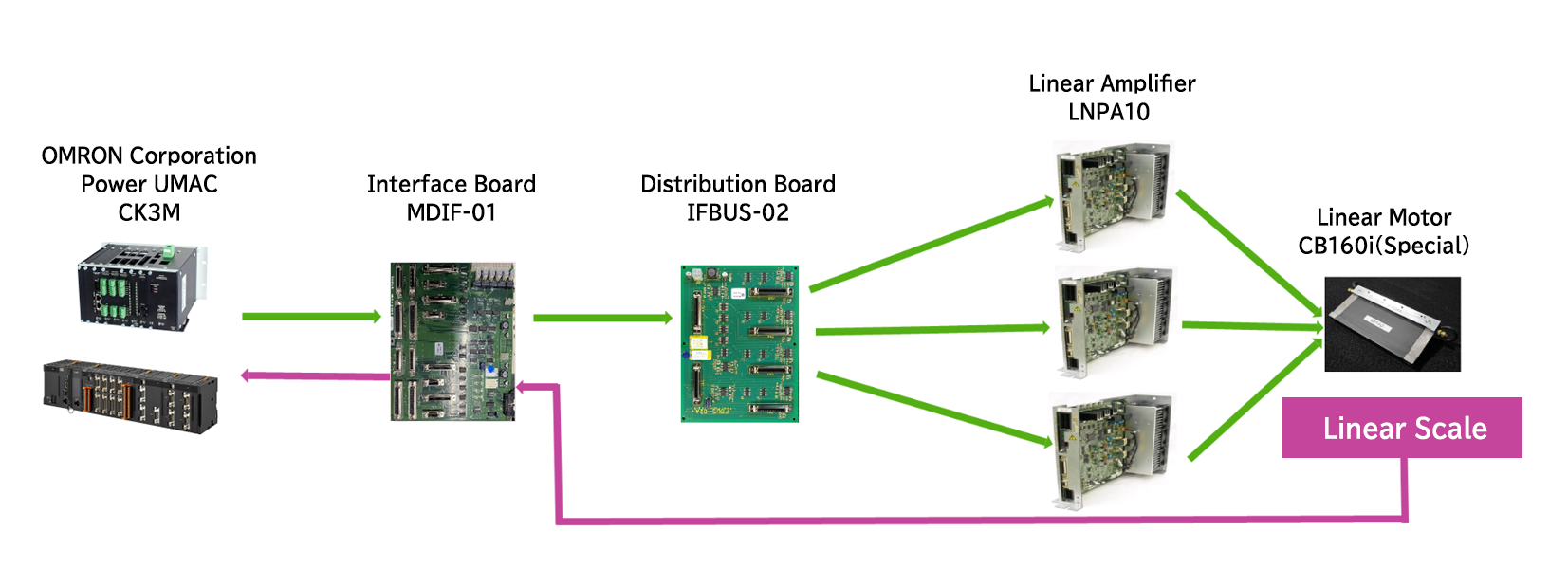

< Using Power PMAC and CK3M >

OMRON Corporation Power PMAC, CK3M, in addition to high-speed arithmetic, directly receives position feedback and maintains synchronization even in multiple axes.

and position feedback is received directly, synchronization is maintained even in multiple axes.

In addition, the use of sodic linear amplifiers and high-frequency amplifiers nano order accuracy can be achieved by using sodic linear amplifiers and high frequency amplifiers.

For more information about Power PMAC and CK3M, click the banner below.

Introduction of High-precision Systems

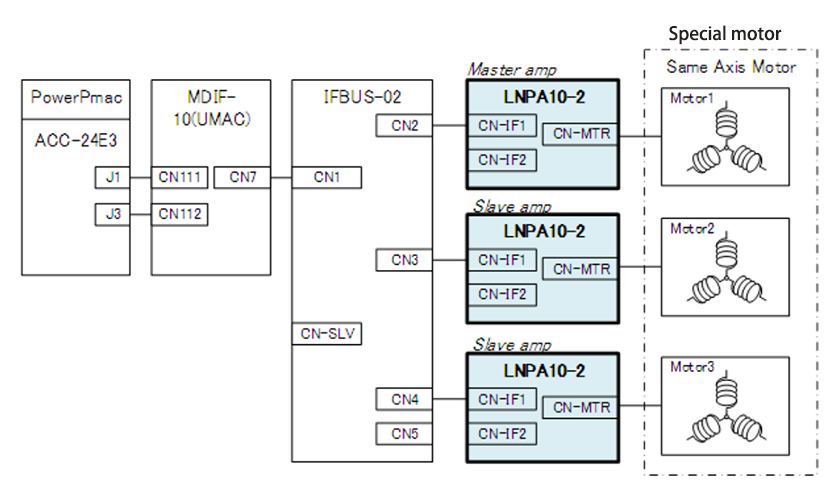

< Power PMAC, CK3M and Linear Amplifier Configuration >

It consists of Power PMAC, CK3M and linear amplifier.

The linear motor (CB160i special) has a structure that integrates three motors.

Up to three linear amplifiers can be used depending on the required capacity.

We can also provide boards and harnesses.

We have delivered to manufacturers of measuring instruments and inspection equipment that require nano-order accuracy.

We have a track record of delivery to manufacturers of measuring instruments and inspection equipment that require nano-order accuracy.

Please feel free to contact us for more information about accuracy.

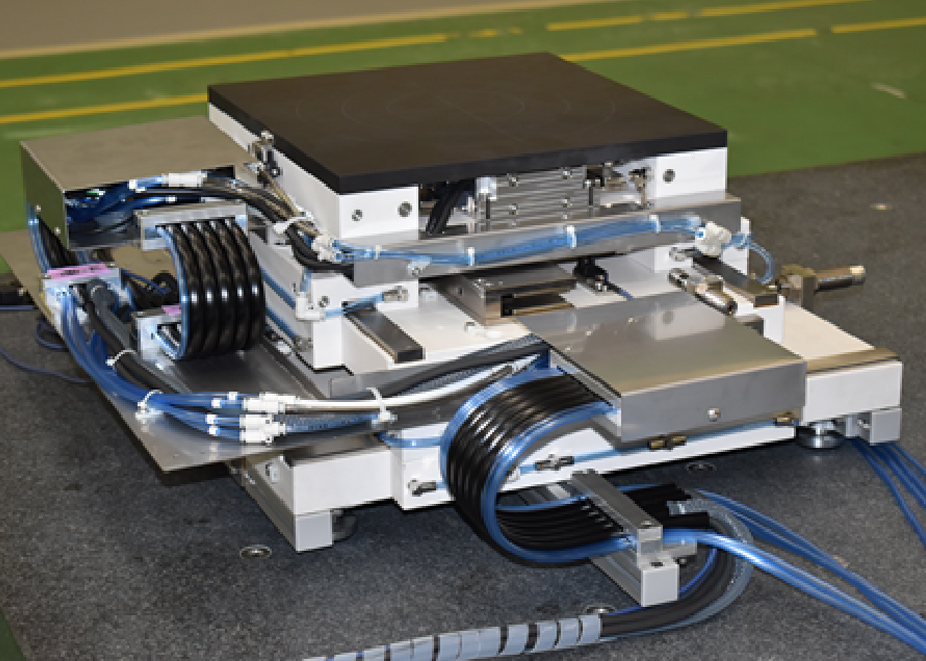

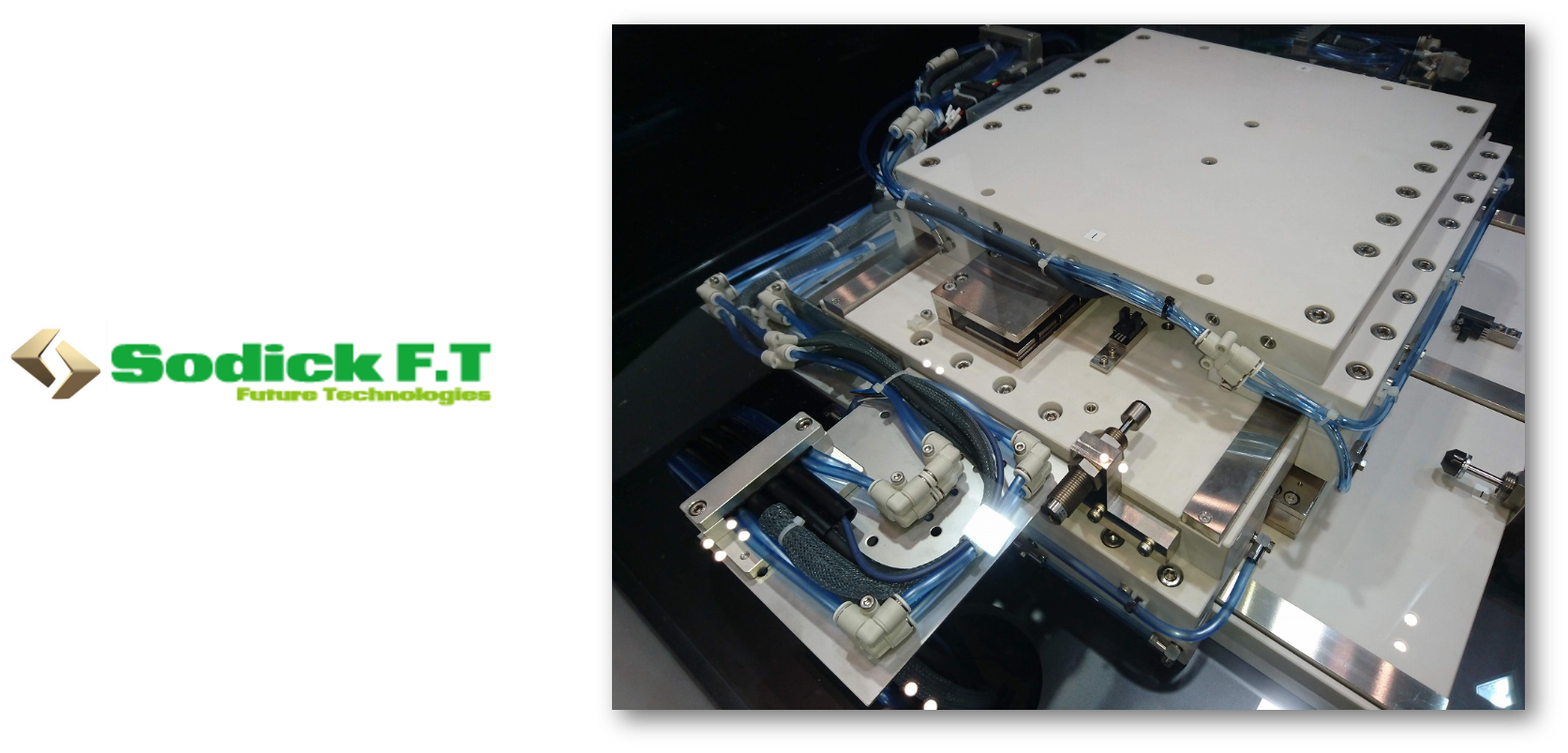

Case Study (2)

Combination of linear motor and ceramic components

Combining a linear motor with a ceramic component enables the realization

of ultra-high precision stages, etc.

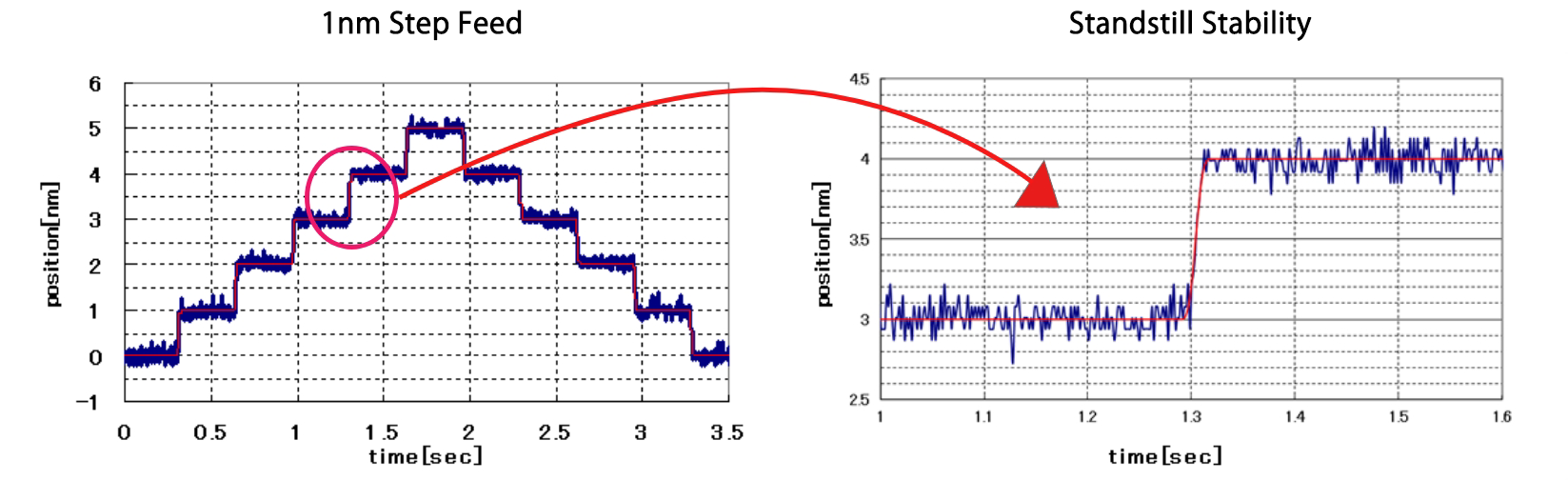

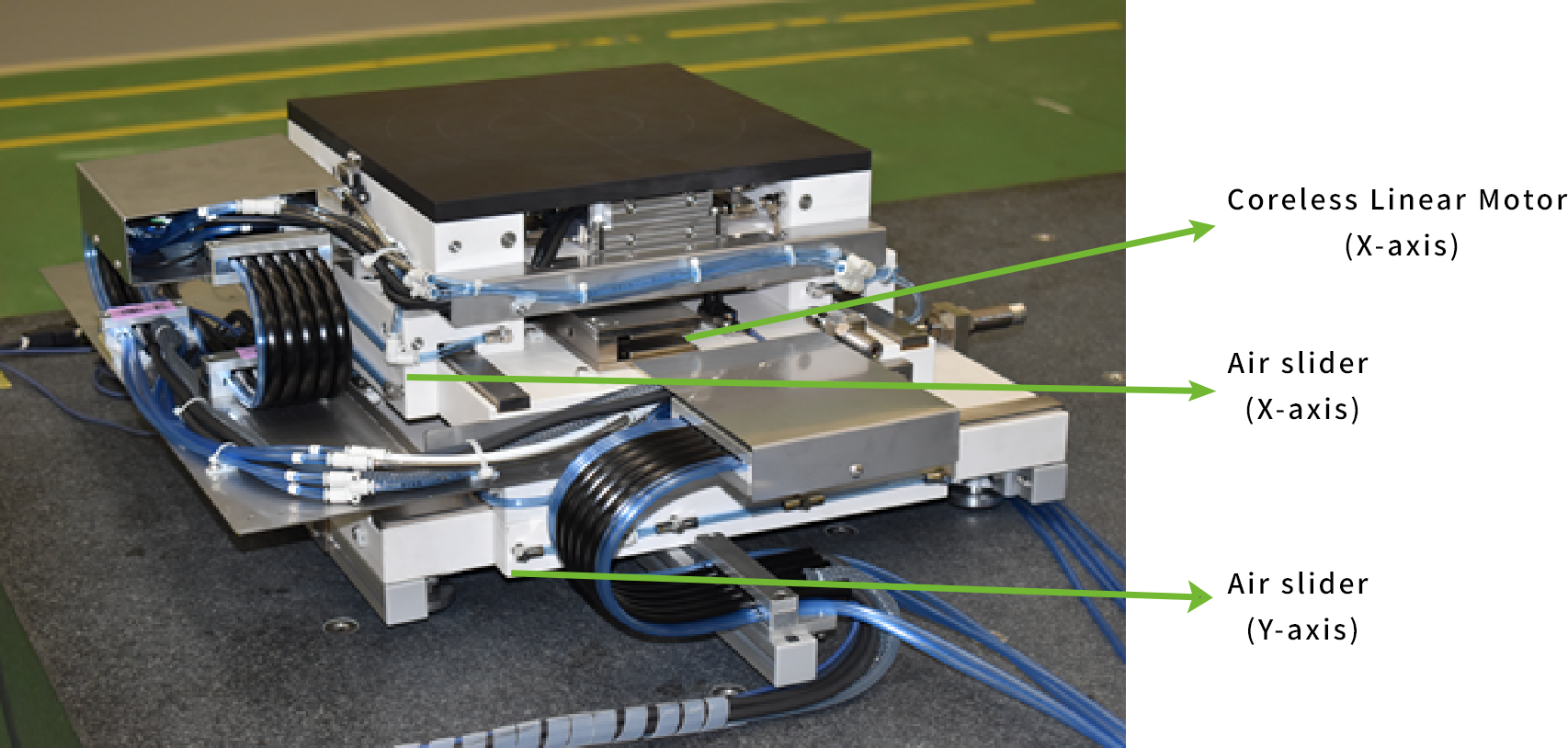

Ultra-precision XY theta stage (using coreless linear motors for both X, Y, and theta axes)

Features

- Low center of gravity, low thermal expansion, light weight, position deviation: less than 5 nm.

- Coreless linear motors are used for all axes, and cordierite with low thermal expansion is used for the table and slider sections.

Main specifications

| Stroke | X-axis:120㎜、Y-axis:160㎜、Θ-axis:±4㎜ |

|---|---|

| Feed velocity | 0.1m/sec、Acceleration:0.25m/sec2 |

| Stage position deviation | P-P:below 5nm |

| Vertical true straightness | X-axis:below 0.5μm/100mm、Y-axis:below 0.5μm/100mm |

| Horizontal true straightness | X-axis:below 0.5μm/100mm、Y-axis:below 0.5μm/100mm |

| Θ-axis specifications | Squareness:below 2μm、Position deviation:below 5nm |

| Squareness | below 0.5μm |

| Flatness | X、Y-axis both:below 5μm |

| External dimensions | W600mm x D550mm x H235mm |

| Total weight | 104Kg |

| Linear motor used | X、Y-axis both:Coreless linear motor |

| Ceramics used | X、Y-axis both:Cordierite Θ-axis:Black cordierite Cordireite:Thermal expansion coefficient 0.1×10-6℃(20~25℃)、Specific gravity:2.5 |

*Accuracy measurement environment:Temperature23℃±1℃、Humidity:50~60%

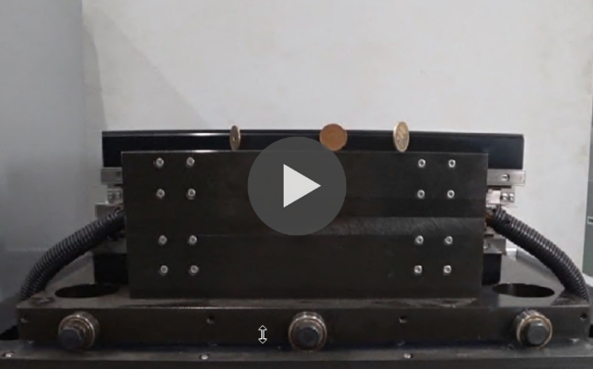

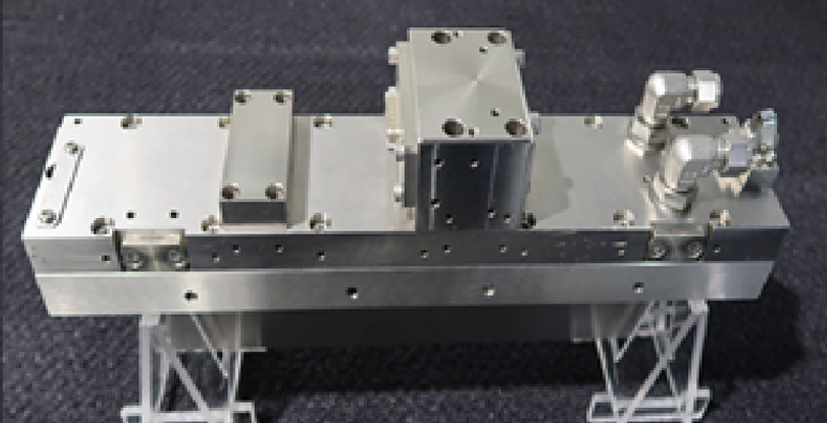

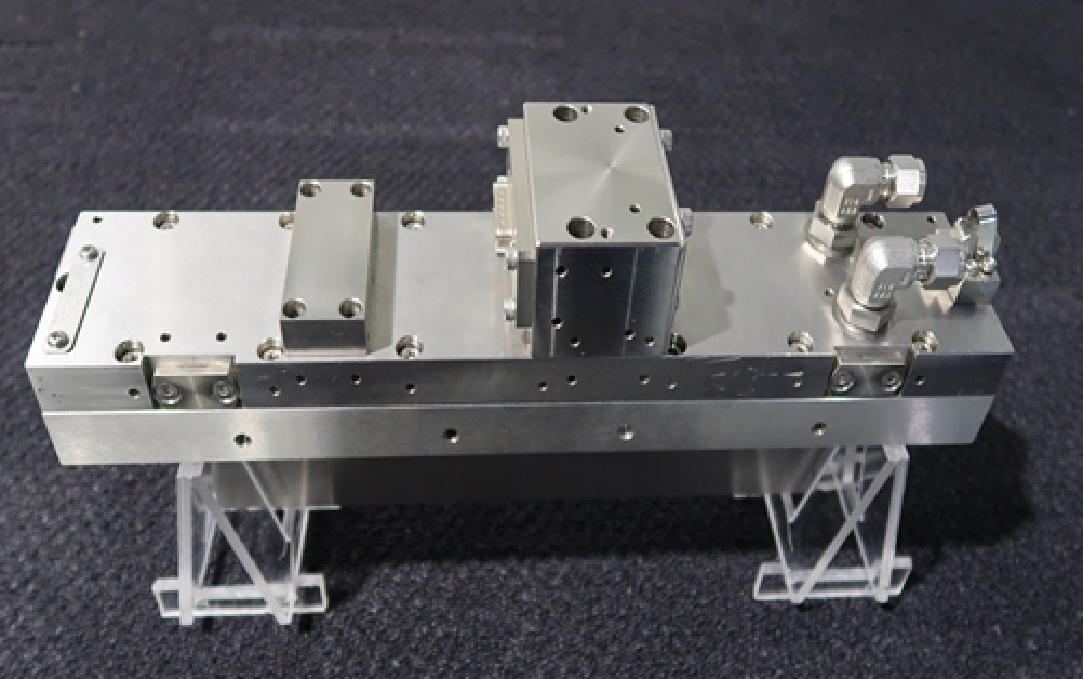

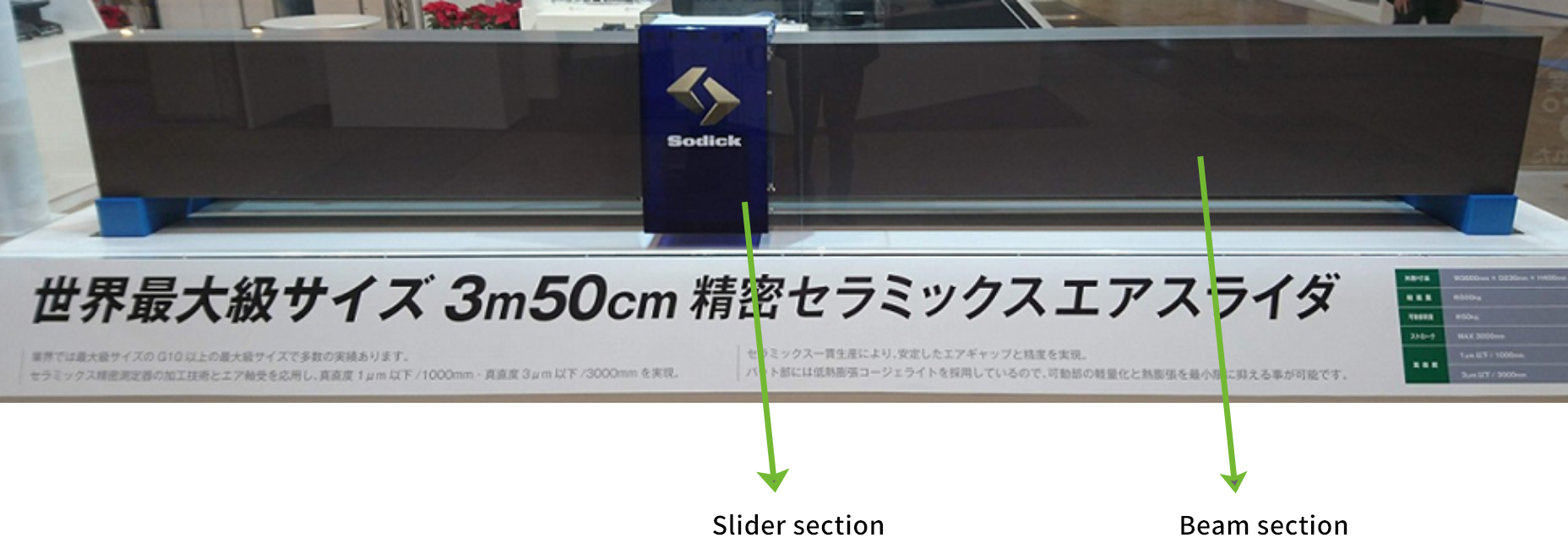

Large air slider (drive motor: coreless linear motor)

Slider drive unit

Main specifications

| Stroke | 3000mm |

|---|---|

| Straightness | below 5μm/3000mm |

| External dimensions | W3550mm x D230mm x H400mm |

| Weight of movable parts | 50Kg |

| Total weight | 500Kg |

| Linear motor used | Coreless linear motor |

| Ceramics used | Beam section:Alumina-based Slider section:Cordierite Alumina-based:Thermal expansion coefficient 4.8~5.5×10-6℃(20~100℃)、Specific gravity:3.6~3.9 Cordierite:Thermal expansion coefficient 0.1×10-6℃(20~25℃)、Specific gravity:2.5 |

- For both stage and air slider:

Linear motor and control system components (Sodick)

Design and assembly of the main body and ceramic materials (in charge of Sodick F.T. EMG Division)

SodickF.T Case Studies

Adopted for Sodick F.T ultra-precision air slide stageAdopted for Sodick F.T ultra-precision air slide stage.

Sodick F.T. Jump to Introduction to the stage using cordierite with zero thermal expansion!!