Incorporating Sodick ceramics achieved accurate machining conditions.

Looking into the future, Sodick tackled the next issue.

That was how to achieve smoother and faster movements during machining.

Sodick developed this original advanced technology in-house and

was the first in the world to introduce it into mass-produced machine tools in 1998.

Conventional drive systems were unable to ensure stable and reproducible motions due to backlash and play resulting from wear.

So, Sodick adopted linear motor technology.

Sodick developed its original, in-house manufactured linear motors and incorporated into machine tools.

High speed and accurate stopping.

Quick movements and accurate stopping,

even after 10 years' operation.

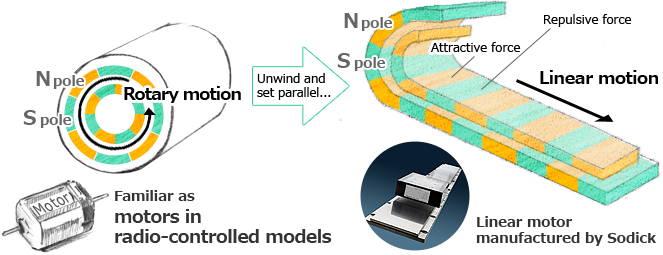

First of all, just what is a linear motor?

First of all, just what is a linear motor?

It is a motor that generates thrust through magnetic attraction and repulsion.

It is a linear motion motor, rather than a rotary motion motor.

Because the train floats on magnets and has no wheels it moves much more smoothly.

Why are linear motors used in machine tools?

Why are linear motors used in machine tools?

A conventional ball screw drive has mechanical contact in the parts that convert the motor rotations to linear motions. Wear may occur in these parts after a long period of use and therefore the motor rotations are not accurately transmitted to the machine.

This is called backlash. A gap may form between the feedscrew and nut when the direction of motion is reversed, causing looseness in the mechanical movements and greater positioning errors.

On the other hand, a linear motor drive operates through attraction and repulsion between S and N poles of magnets and no contact occurs.

Hence no backlash exists.

This makes it an ideal drive system for machine tools that perform high-precision work.

Conventional ball screw drive system

Contact occurs during movements, so that wear occurs.

* The video will play with the sound.

Linear motor drive system

Lack of contact allows smooth movements!

* The video will play with the sound.

A linear motor comprises only two parts—a magnet plate and linear coil unit—so that the feed mechanism is simple.

It requires no accurate positioning between the motor and ball screw, as in a ball screw drive system, making assembly and adjustments simple and achieving stable quality and performance.

What are the features of Sodick linear motors?

What are the features of Sodick linear motors?

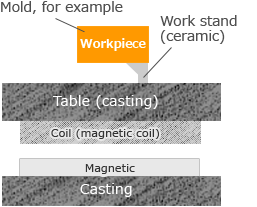

Sodick linear motors are arranged flat, so that the magnets and coils can be directly attached to structural elements such as the machine table and bed.

The linear motor directly transmits the driving forces to the machine with no losses and maintains high responsiveness for a long period of time.

The flat arrangement allows the linear motors to be enclosed in a low space, achieving a low center of gravity of the table drive mechanism and permits stable drive performance.

In addition, a conventional ball screw drive system contains many parts and requires a high level of skill to assemble and adjust it.

In other words, the dynamic accuracy is dependent on the assembly accuracy, which is affected by the level of skill of the worker.

However, Sodick machine tools employ linear motor drives that have few parts, are easy to assemble and adjust, and move accurately with stable performance over a long period of time.

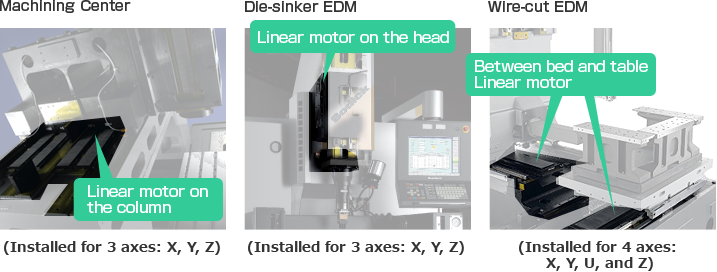

Where are linear motors used in Sodick products?

Where are linear motors used in Sodick products?

Actually, no technology originally existed to apply this fast and accurate linear motor performance to machine tools.

Despite having these ideal motors, no control technology was available to exploit their performance.

So, Sodick developed dedicated motion control technology for machine tools in-house.