Non-wearable electrode circuits, Loran technology, Sodick NC units, ceramics, linear motors, and K-SMC motion controllers have been incorporated to significantly enhance the machining accuracy of mold components produced by Sodick wire-cut electrical discharge machines.

Although these elements improve the overall accuracy of the assembled mold, customers who install such a mold in an injection molding machine and produce plastic parts sometimes ask why they can’t achieve the expected high-precision molding with their existing injection molding machine.

To respond to such customer requests, Sodick began the development of a plastic injection molding machine that is an industrial machine, a totally different class from machine tools.

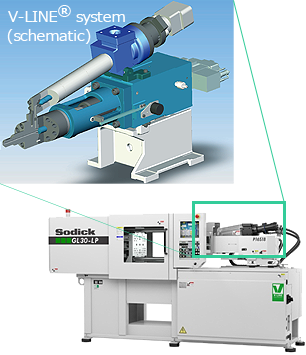

Sodick V‒LINE® injection molding machine

Sodick V‒LINE® injection molding machine

Sodick started the development based on the question: “Molding is not working as we hoped. Is there some problem with our existing technology?”

Our investigations showed that modifications were required in the processes to melt the plastic material, accurately weigh it, and inject it into the mold.

We noticed a problem with the inline screw system that has been widely used until now.

We realized that the inline screw system depends on a fine balance of these processes and can lead to unstable molding.

To overcome these problems, Sodick developed the

V-LINE® system.

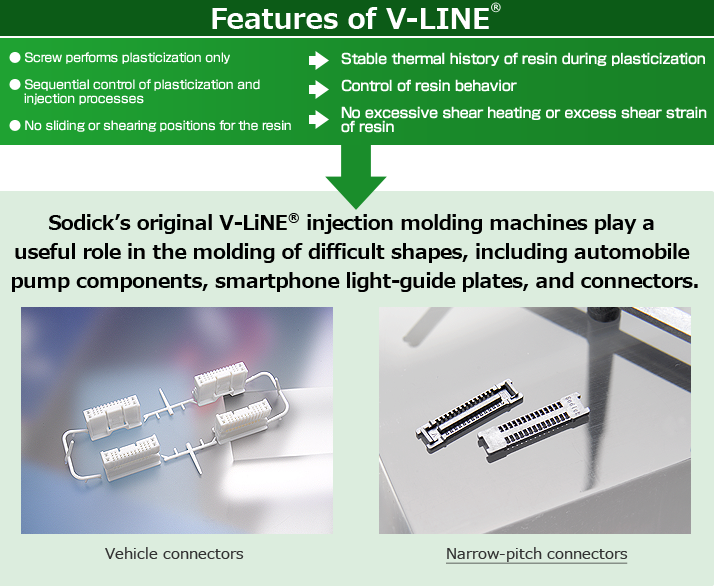

In the V-LINE®, the processes previously handled by a single screw were separated to successfully eliminate the factors leading to instability.

The revolutionary V-LINE® system technology is now incorporated in all Sodick injection molding machines.

What is plastic injection molding?

What is plastic injection molding?

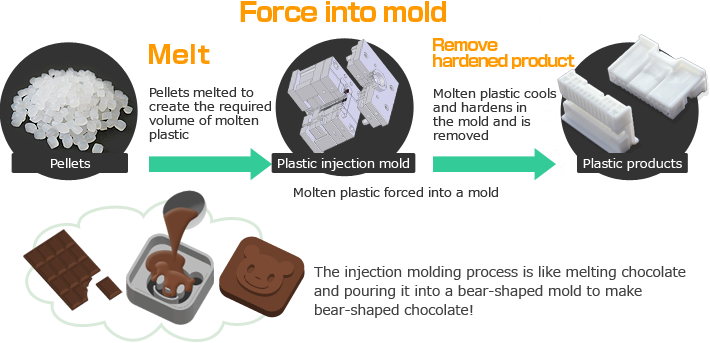

We are surrounded by a lot of plastic products.

Plastic injection molding is a method for manufacturing these products and it forms plastic pellets into practical products we use every day.

The raw material for plastic products is small plastic particles called “pellets.”

Injection molding involves three processes: melting the pellets, forcing the molten plastic into a mold, and removing the hardened plastic.

A machine that makes such plastic parts is an injection molding machine.

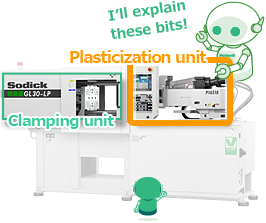

This machine mainly comprises a plasticization unit that melts and feeds the plastic and a clamping unit that opens, closes, and clamps the mold.

What is plasticization

What is plasticization

and injection?

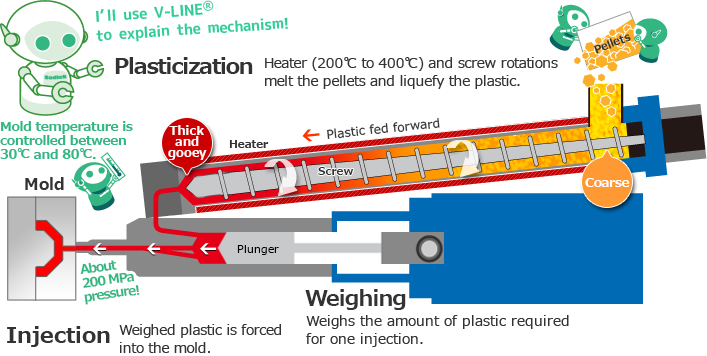

Injection molding involves the three processes of melting the pellets, measuring the required volume, and feeding the plastic.

These processes are respectively called “plasticization,” “weighing,”

and “injection.”

First, tell us about the inline screw system.

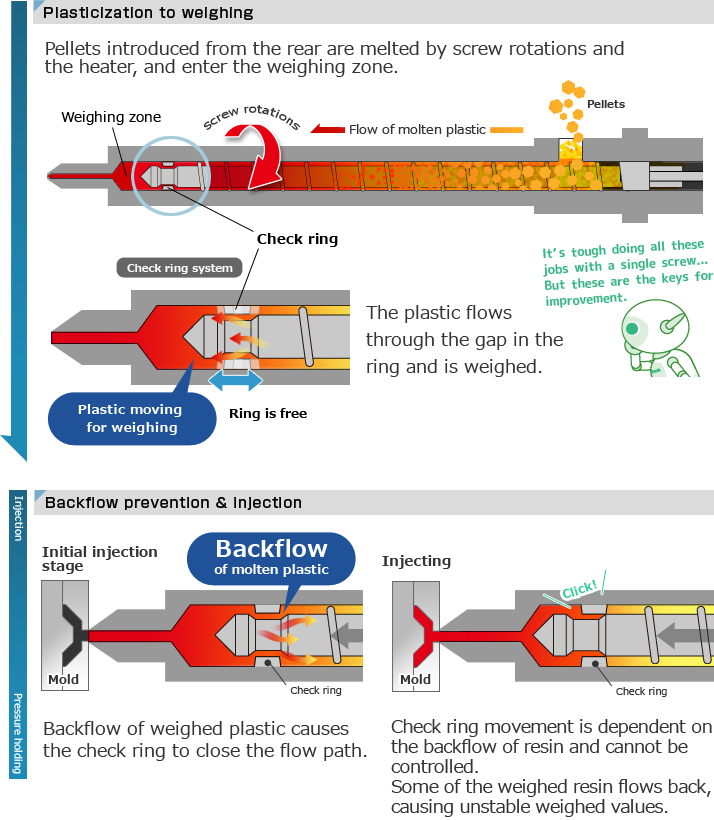

In the inline screw system, the screw and injection cylinder are arranged coaxially. Plasticization (melting) of the material and injection are handled along the same axis.

A feature of the inline method is the check ring that moves backward and forward to shut off the plastic flow.

The check ring allows the plastic to flow freely during plasticization but shuts off the backflow of plastic during injection.

Inline screw system

How is V-LINE® different from

the conventional method?

V-LINE® is

the name of the plasticization mechanism for injection molding machines developed by Sodick.

It is generally known as a “screw preplasticating system” and Sodick’s V-LINE® is a mechanism with improved preplasticating mechanism.

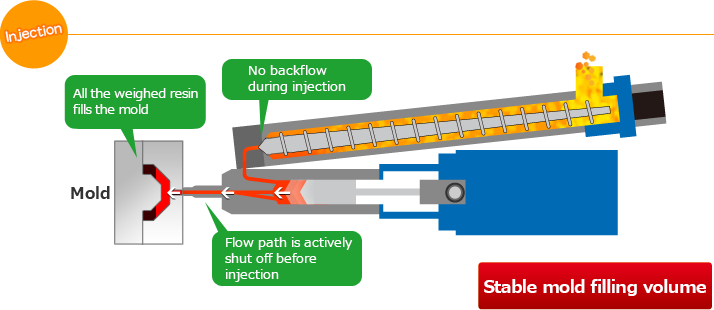

The major feature of V‒LINE® is the stable molten condition during plasticization and stable filling volume it achieves by separating the plasticization and injection processes.

* The video will play with the sound.

V-LINE® system

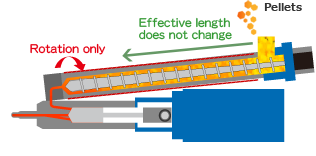

Pellets gradually melt due to the screw rotations

and the heat from the heater.

As the screw rotates in the same position,

the plastic receives the same thermal history.

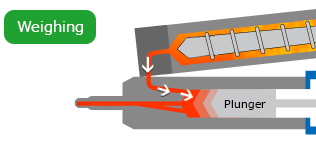

Exactly the right amount of molten plastic for injection is fed to the plunger.

When the required amount of plastic is reached, the screw advances to shut of the flow path.

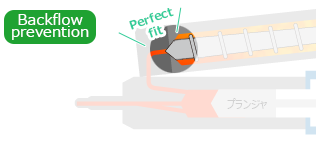

The screw tip prevents backflow and securely shuts off the flow path.

Thanks to the development of the V‒LINE® injection molding machines, we can now mold defect-free plastic products using molds made by Sodick wire-cut electrical discharge machines and machining centers.