History of Our Technology

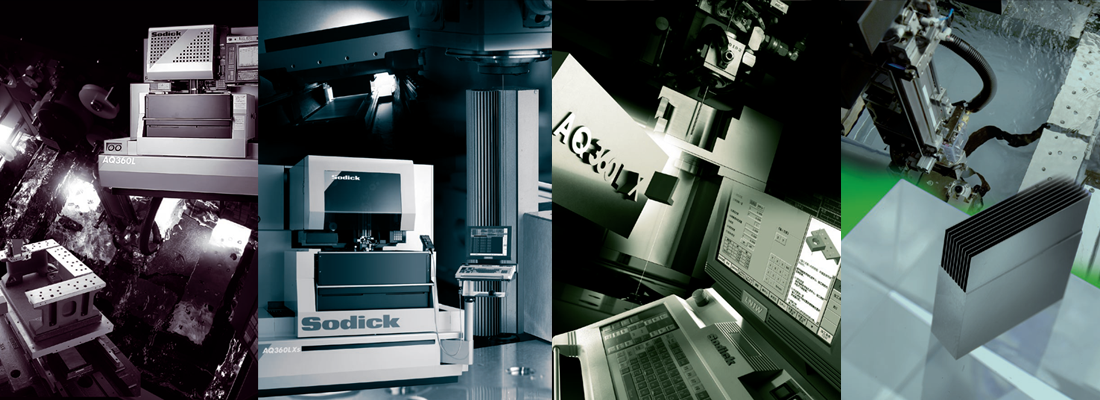

Sodick's technological footstep began with electrical discharge machining

Sodick's footsteps: not only Japan's technological innovation history but also the history of Sodick technology.

Japanese manufacturing acknowledged by the world

Today, Japanese products are highly evaluated worldwide for its high quality and excellent performance profile. This credit is the fruit all by technological innovation of machine tools, which are the mother machines for manufacturing.

What technological innovation brings about

As a familiar example, mobile phone devices which were difficult to carry around twenty years ago have become compact and highly functional tablet devices represented by smartphones and have become essential items in our lives. This could not have been achieved without the development of machine tools that fabricate molds for manufacturing.

Sodick's technological footsteps

The start of Japanese technological innovation is NC technology, which Sodick tackled early on. Sodick's technology started with the idea of attaching an NC unit to freely control motors for electrical discharge machines. By wedding a proprietary NC unit to existing EDM technology, the GPC Series power supply for NC Die-sinker EDM was born (1977). Further, by adopting numerical control (NC) unit with this Die-sinker EDM, mold accuracy has been dramatically improved.

Sodick then challenged to develop ceramics, which is a material with high rigidity and a small coefficient of thermal expansion, to serve as the structural material of machines in order to achieve even higher precision positioning, and Sodick completed NC Wire-cut EDM 330W with 5-axis simultaneous control using that technology (1981).

In this way, Sodick developed the NC Unit (a numerical control unit) in-house, which sends instructions to operate high precision positioning and electrical discharge machines having a machine structure that allows metal processing at higher precision. In line with such development, Sodick developed technologies one after another, including linear motor technology allowing moving machines at high speed and with a high degree of accuracy to perform processing and Sodick Motion Controller (SMC) that provides high speed, high precise control of the movement of linear motors based on instructions from the NC unit.

Around that time, we often heard from customers about unstable quality of the final plastic parts even with the use of high accuracy plastic molds, which were created with Sodick's EDMs. With that, we decided to self-develop and manufacture molding machines ourselves. As a result of our research, we developed unprecedented, new injection plasticization mechanism called the V-LINE® System. This new machine divides the plasticization part that melts the plastic resin and the injection part that injects melted resin into a mold. Together with the V-LINE® System, we also completed a hybrid molding machine equipped with a Straight-Hydraulic Mold Clamping System that closes molds straight. This drastically improved reproducibility of products compared to conventional molding machines and also reduced machine deviation.

In the machine tool field, not only did we pioneer sequential control of machine tools but also developed programmable logic controllers (PLC), which allows automatic control of a wide range of industrial machines based on control technology cultivated with the aforementioned Sodick's Motion Controller (SMC). Furthermore, in 2012, we developed a 19 inch multi-touch LCD CNC Unit for achieving smartphone-like operability ahead of our competitors. This shows our strengths in the attitude of approaching further for newer development. Sodick offer the promise of many new possibilities for machine tools even now.

Technological innovations like these stated above led to Japan's technological innovation at the same time to complete everything in compact form fact and with high performance, improving and achieving unwavering position of Japan's manufacturing.

Future development

Sodick's technology continues to move forward to put make our dreams reality as a manufacturing leader and attaining quick response to realize customer needs in the ultra-precision processing field (sub-micron to nano level).