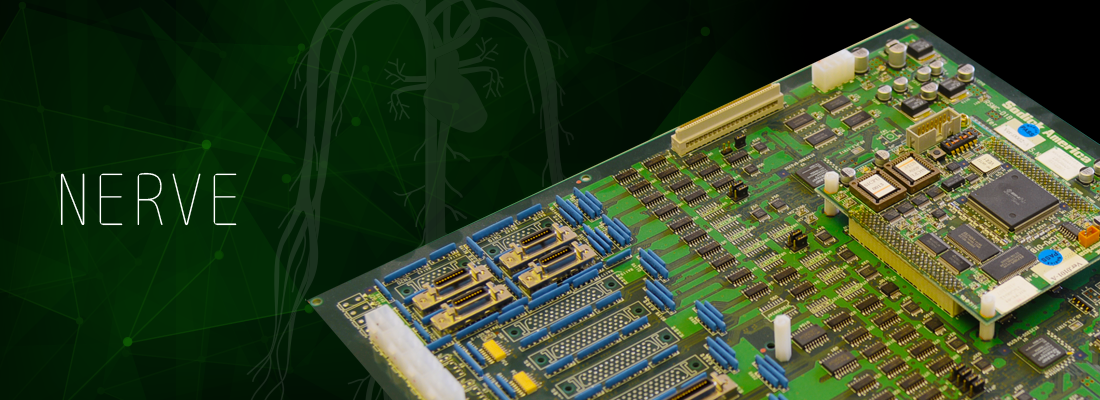

Core Technology 05 Motion Controller

Motion controller: The“nerves”of Sodick products

Created with the mission on how fast and accurately a linear motor can be moved

About Motion Controller

The role of a motion controller lies in controlling high speed and high precision movement of the linear motor in line with instructions from a NC unit. Sodick owns motion controller manufacturing technology for linear motors that uses PID control and modern control to achieve high speed, high acceleration control, as well as copyrights on the replication and use of the software used to control the linear motor.

Features

- Sliding mode control

- PID (Proportion Integration Differential Calculus) control

- Number of control axes: 8-axes (maximum)

- Number of encoder axes: 12-axes (maximum)

- Disturbance observer

- Notch filter

- Current loop:20 μs (minimum setting)

- Position-velocity loop: 100 μs (minimum setting)

- Segment time: 500 μs (minimum setting)

Background of Development

While we develop NC unit, which determines the overall performance of the machine, the accuracy of sending directions to the movement of the linear motors (i.e., the muscles) becomes essential in order to improve precision. What required here is the motion controller to calculate precise movement and send directions. Instead of remaking existing products, we developed our own products from scratch with the intent to create products to fit Sodick products. We established a development company in San Jose, California, a locus of the world’s top-class technology information, newly developed motion controllers, and brought about a technological revolution in Sodick electrical discharge machining technology. To this day, we are working on R&D for future generations.