Environmental Initiatives

Promoting Environmentally-Friendly Products

Contributing to the environment through products

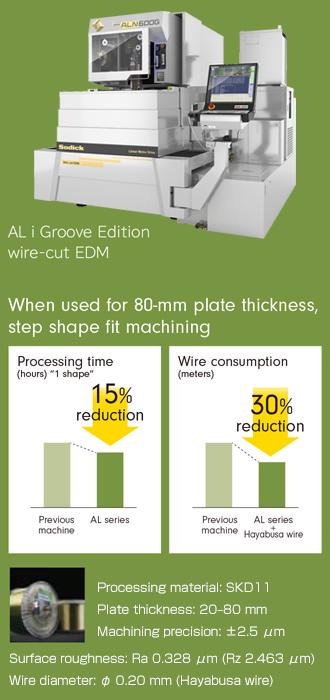

Machine Tool Segment

The performance of machines used in the process of product manufacturing has a major effect on the environmental impact of manufacturing. In the case of power units, for example, electric power consumption and the amount of consumables used can be reduced by increasing the processing speed to shorten the processing time. With machines as well, the number of processes and time required can be reduced by increasing machining precision. Since its founding, Sodick has developed a succession of core technologies in-house that have significantly enhanced the performance of the machines we provide to customers, thereby continuously contributing to the reduction of our customers’ environmental impact through our products. In 2020, we developed the AL i Groove Edition, the world’s first wire-cut EDM equipped with a “wire rotation mechanism,” which enhances quality in terms of machining and reduces the amount of wire consumed.

In another effort to make effective use of resources, we have established the world’s first recycling technology that produces the same quality as original electrode wire, which is essential in electrical discharge processes. After processing at the customer, the used electrode wire is collected, melted, and recycled into electrode wire that can be used in high-precision processing.

Industrial Machinery Segment

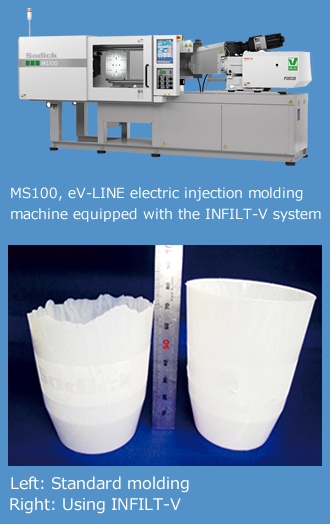

Sodick’s injection molding machines for plastics, difficult-to-machine materials, and light metals are used to mold parts for things including automobiles, telecommunication equipment, electrical and electronic equipment, and medical equipment. By pursuing technological innovation in injection molding machines, we have not only improved yields and reduced resource waste, but also achieved compactness, thinness, lighter weight, and higher quality in a variety of finished products. With the growing popularity of electric vehicles and 5G telecommunications, DX, and advances in areas like minimally invasive treatments*, Sodick’s technologies are making a behind-the-scenes contribution.

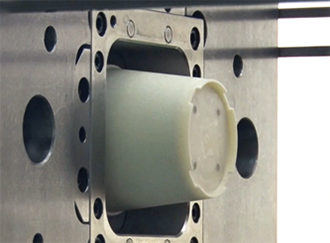

The INFILT-V system, which we successfully introduced during 2020, can easily mold thin and deep biodegradable plastics that were previously difficult to handle. With environmental pollution from plastic waste, including marine plastic waste, becoming a global problem, it is preferable to use biodegradable plastic that decomposes into the earth if discarded, but to date its use has been limited because it is difficult to mold. With INFILT-V, our proprietary V-LINE® injection molding machines, which are designed for high-precision molded items, are able to use biodegradable plastic. We expect to promote its widespread use.

*Medical treatment that minimizes pain, fevers, and bleeding in patients who undergo surgery and tests.

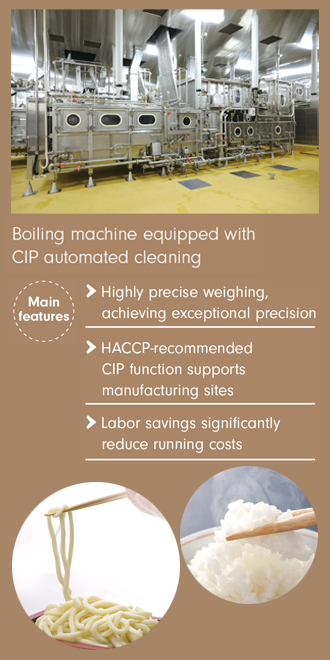

Food Machinery Segment

Japan is blessed with abundant food, but food shortages and hunger are major problems around the world. Noodles and rice are good, extremely efficient food ingredients; by boiling them the raw ingredient can be processed into finished products that are two or three times the volume of the raw material. Sodick has strengths in development and manufacturing equipment that is able to produce noodles and cooked rice continuously and with stability, and we aim to use technology to help resolve society’s food issues.

Sodick’s main products are boiling machines equipped with CIP automated cleaning that were initially developed 25 years ago from the perspective of HACCP*. CIP is a system that automatically cleans the inside of the equipment in a fully automated process from boiling and cooling to measuring, allowing for stable, safe production. By reducing the count of viable bacteria during processing, the extended shelf lives for noodles are highly regarded by major noodle manufacturers and convenience store vendors. Sodick hopes to contribute to enhancing food safety and food culture around the world with this equipment and other technologies for sterile-packed cooked rice production and automation equipment for confectionery and Japanesestyle deli dishes.

*HACCP: Hazard Analysis and Critical Control Point; an international food hygiene management standard

Granule Powder Cooling System is quickly and evenly cools granular raw materials including wheat flour, buckwheat flour and rice flour. Improves the dough quality and shortens cooling time in fields including noodle-making, bread and confectionery production, and also significantly cuts power consumption for cooling.

Recycling

The world’s first electrode wire, adapted to used-wire recycling systems, eveloped and manufactured in-house. Built using high-quality and high-precision production processes to offer superior straightness and an extremely smooth surface quality. It fully elicits machining performance that is highly reliable.

An ion exchange resin system included with wire-cut EDMs (water pecification), with an extended operating life making it well suited to long-duration machining. Its 18-L capacity is approximately twice that of conventional types. The “canister” itself is replaceable, so there is no need to perform the work of refilling the resin. This makes for an environmentally-friendly product.

Inherited the performance of our extended life SHF-25E model. Its operating life is approximately twice that of conventional products (compared with Sodick’s HF-25A).

Type of filter with a structure that allows for disassembly (filter paper and outer frame). Depending on the rental contract, the product can be put into the distribution cycle and collected.

Initiative for waste

Biodegradable Plastic Molding Technology Initiatives

Research and development of plastics that biodegrade in natural conditions such as soil and water is currently drawing attention. Biodegradable plastic is a type of plastic that eventually breaks down completely into a natural

by-product (such as carbon dioxide and water) through the action of microorganisms that exist in the natural world. This helps to resolve the problem of microplastics, which remain when plastic waste does not break down naturally, and by becoming progressively smaller are difficult to recover.

Sodick’s injection molding machines employ the V-LINE® System, a unique mechanism that separates the processes of plasticization and injection. This system demonstrates outstanding performance in terms of the stability of the melted state and heat stability during injection, contributing to stable manufacturing of products made from biodegradable plastics.