Point 1

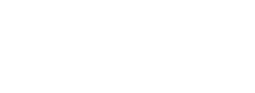

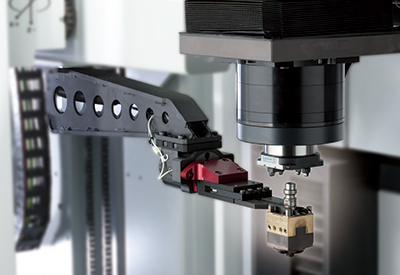

Articulated Robot

Repeatedly performs smooth electrode and workpiece replacement for completely automatic machining of as many as 100 workpieces, or even more.

For Automation

High degree of freedom allows flexible operation

Die-Sinker EDM and an articulated robot.

The articulated robot performs transportation including mounting/removing of electrodes and workpieces. From

the layout of electrodes and workpiece stokers to air blow process and 3D measurement automation, system

upgrades with the articulated robot are characterized by a high degree of freedom. The robot size is

selected according to the weight of the transported object.

The EROWA ITS system we provide has an excellent track record in streamlining

and automation in electric discharge machining.

This tooling system achieves highly precise off-line setup in automation systems. For example, it is

possible to obtain repeat accuracy of 2 μm or less during clamping and perform 90° x 4 centering, and also

because of its excellent clamping performance, operation is possible directly from the electrode

manufacturing process.

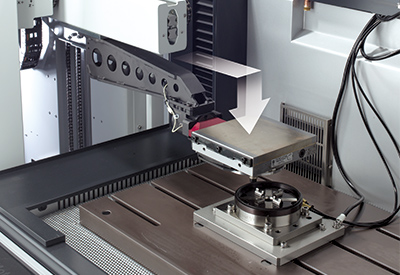

Replacement of electrode or workpiece is achieved with a simple configuration

A combination of the die-sinker EDM and SRC80 (Sodick Robot

Compact 80).The AL series*is

equipped with a three-sided automatic vertical machining tank controlled fully automatically and has a high

affinity with workpiece/electrode replacement systems using automatic electrode changers or robots, allowing

continuous automatic operation with high-precision and high-speed machining.

*AL40G/AL60G

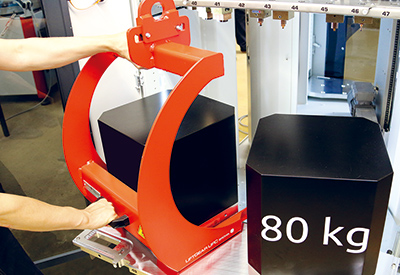

Transportation of heavy workpieces is possible

Maximum transportation load: 80 kg

10 Positions of ITS 148 Pallet

33 Positions of ITS Holders

The starter kit of SRC80 has a type (option) with a scheduler “JMSPro”.

Standard for automatic

electrode replacement

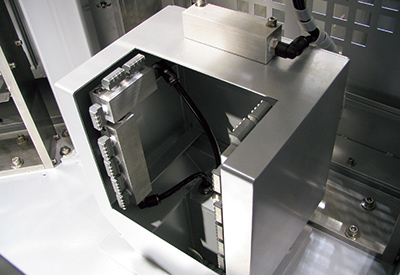

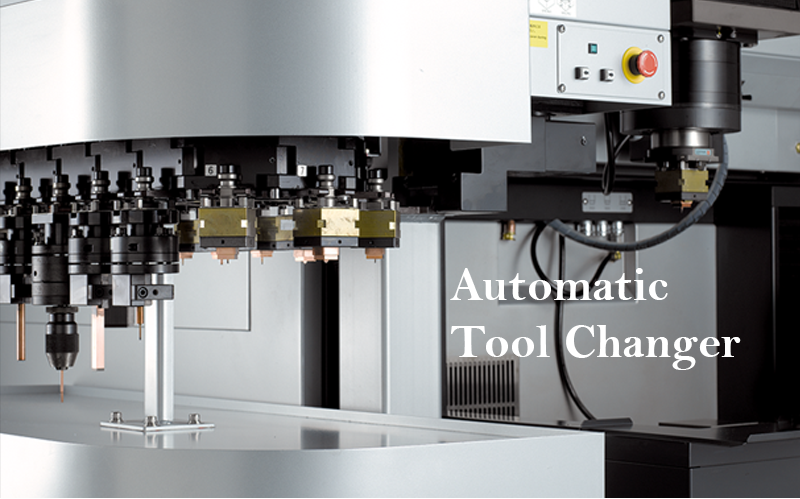

Even if there is no scheduler, the optional ATC specification

enables automatic electrode replacement with a simple, space-saving configuration.

In the AL series, we provide options such as

the stand-alone ATC units “ATC-16E” and “ATC-32E” installed on the left side of the machine, and simplified

and space-saving ATC units “ATC-12S” and “Shuttle ATC” installed on the right side of the machining

tank.

(For compatible models and specifications, contact the responsible sales personnel.)

For Automation

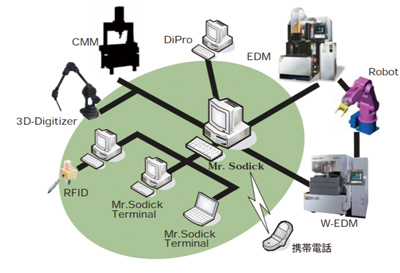

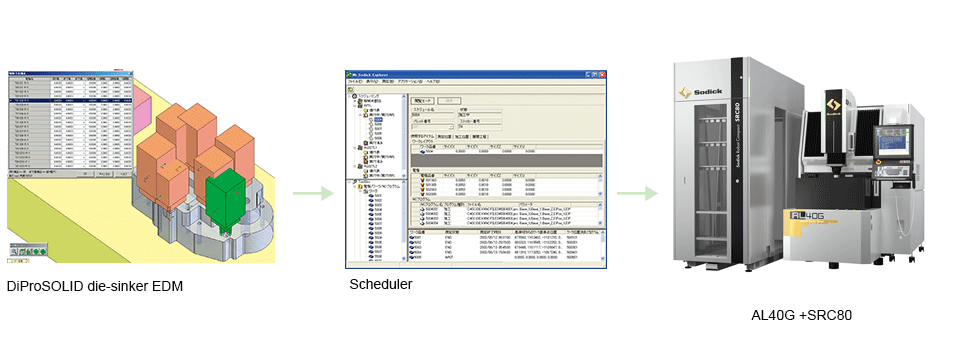

3D CAD/CAM system

developed and manufactured by Sodick

Machining programs can be created from 3D models of products.

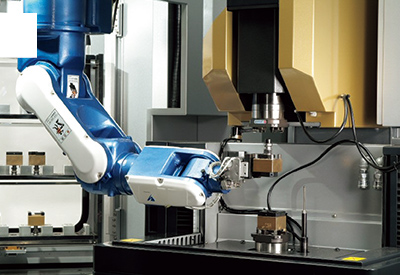

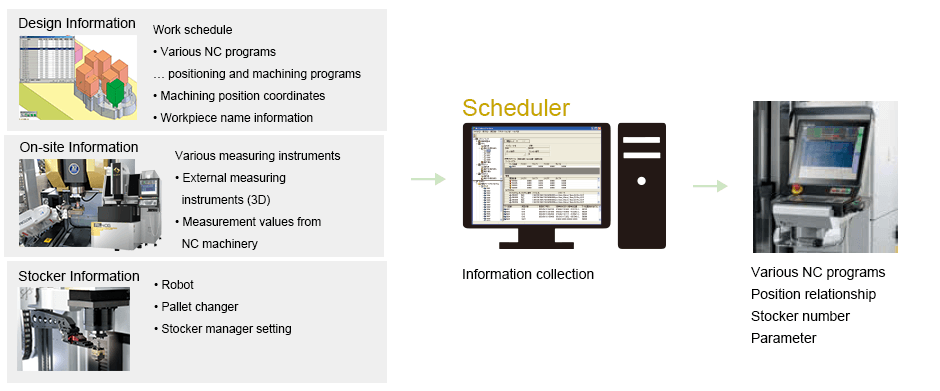

A scheduler that supports automation without cumbersome operations by collecting and managing design information(positioning, machining programs, position coordinates, workpiece information, etc.) and on-site information (measurement values by external units, information from stockers).

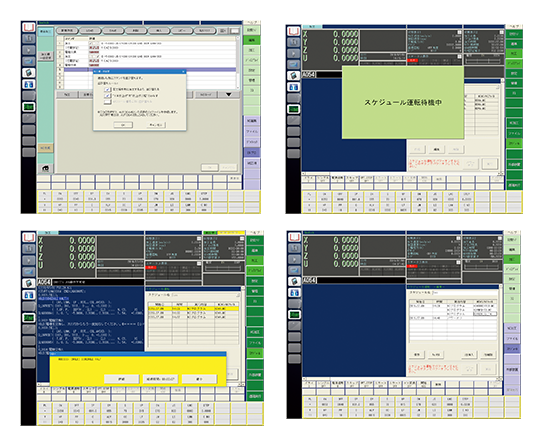

The “LN Professional” machining program creation support function, which is equipped as standard on NC units, enables basic schedule operations with simple input. Requires no advanced knowledge of setup, machining, or schedulers, enabling automatic replacement of multiple electrodes and workpieces.

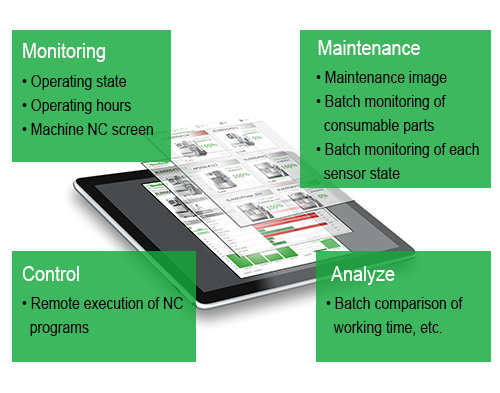

Collects the operating states of each machine, performs batch management and analysis from a remote location, and supports improvement in productivity.

For Automation

AL series

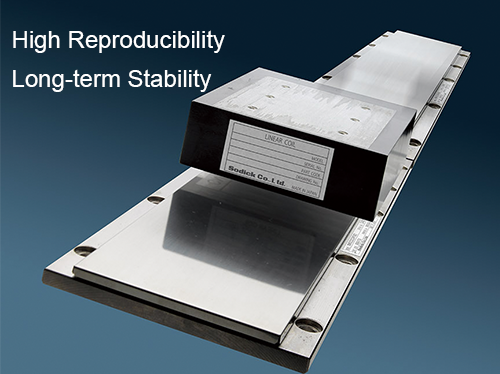

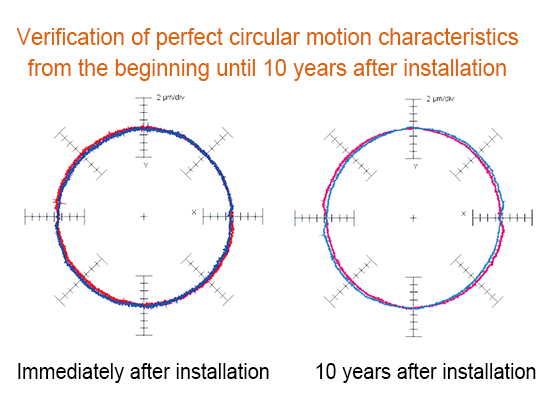

High reproducibility and long-term stability, two

characteristics of linear motor drives, are the most important factors demanded of machine tools in

automation of manufacturing.

Sodick’s die-sinker EDM is equipped with an in-house developed and manufactured linear motor drive on all

three XYZ axes.

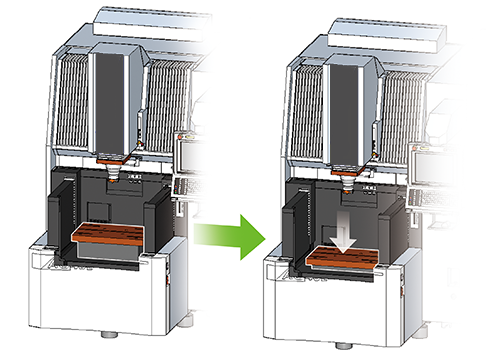

In recent years, there has been increasing demand for use of

rotary tables in machining, and machining by installing a clamp chuck on a table for automation purposes.

While it has been supported by raising the head in the conventional models, in the AG40L, AG40LP and AG60L,

lowering the table achieved a specification that satisfies both open height and machining fluid surface

height, providing a flexible response to the multiple, diverse system setups customers have.

Compatible models:AL40G/AL60G

Equipped with a three-sided automatic vertical machining tank controlled fully automatically, and has a high affinity with workpiece/electrode replacement systems using automatic electrode changers or robots, allowing continuous automatic operation with ultrahigh-precision and high-speed machining. Compatible models:AL40G/AL60G

For Automation

Theme I

Point 1

Repeatedly performs smooth electrode and workpiece replacement for completely automatic machining of as many as 100 workpieces, or even more.

Point 2

Unifies the electrode and workpiece holder sizes, for a structure that reduces complexity when building a system.

Point 3

Machined workpieces are taken out by a robot, and machining fluid is removed in a drying station (air blow process).

Point 4

Provides a change-over station that enables workpieces to be set

and then grasped again from a different angle.

It can be effectively used in a restricted space, such as when machining using a rotating axis or

supplementing the mobile range of the robot.

Theme II

Point 1

Because it can be operated using the simple scheduler function of “LN Professional,” which is equipped as standard on NC units, you can build a simple system requiring no further maintenance after sale.

Point 2

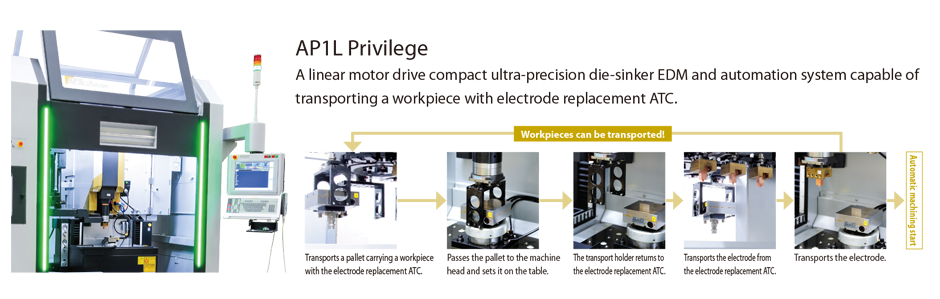

Uses an optional ATC unit for automatic replacement of electrodes and workpieces. Because other robots are not used maintenance is easy to perform.

Point 3

Due to the ATC-based transport, this system has an upper limit to the electrode and workpiece volume, and specializes in small object machining. Based onthe AP1L, which delivers superior ultra-precision machining.

Point 4

Full-cover specifications ensure both suppression of thermal displacement and safety. The 3-color LED changes colors depending on the operating state.

Theme III

Point 1

The system adopts a SRC80 with a maximum transport load of 80 kg. Performs dynamic production with two AL60G units while automatically replacing workpieces and electrodes of various sizes.

Point 2

Automates parts of the off-line setup during machining. Simple presetter performs measurement for the next workpiece, enabling continuous accurate, stable machining performance.

Point 3

Centering around a single robot, multiple machines are arranged in a orientation of point symmetry. Runs the same NC program on two AL60G units.

Point 4

Software system constantly monitoring program execution enables real-time checking of machining progress even from a remote location.