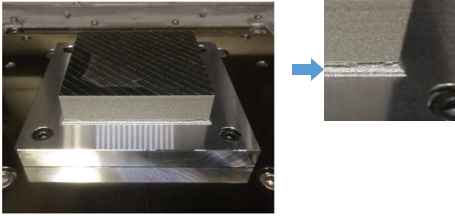

Reverse warpage due to expansion after molding

In the worst case, cracks occur

Use of the SRT method achieves stable molding and high precision

Sample molding of

180 mm x 150 mm x 30 mm without warpage

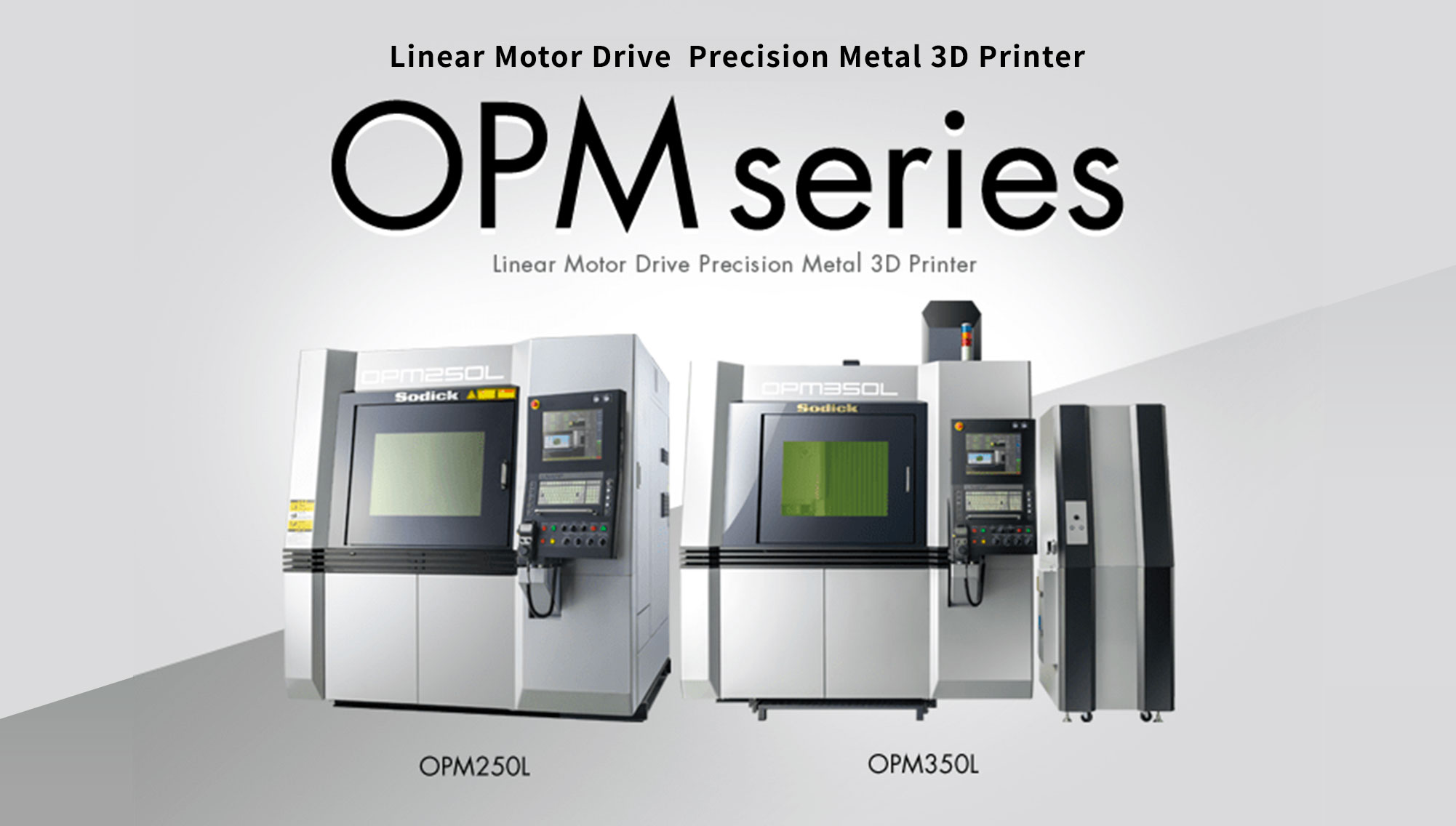

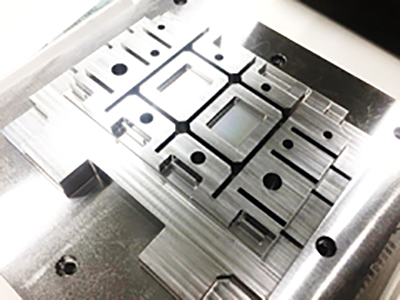

Parts molding examples

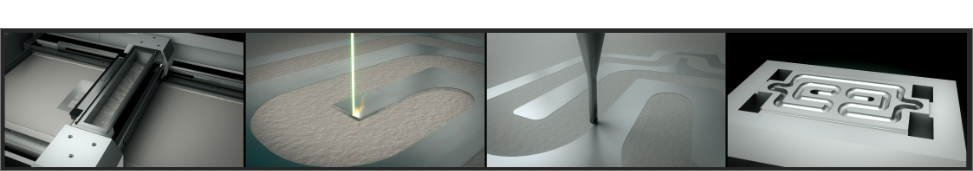

Handles various materialsBenchmark service

We accept orders for benchmark tests for various materials. *The image includes a conceptional drawing generated by a 3D model.

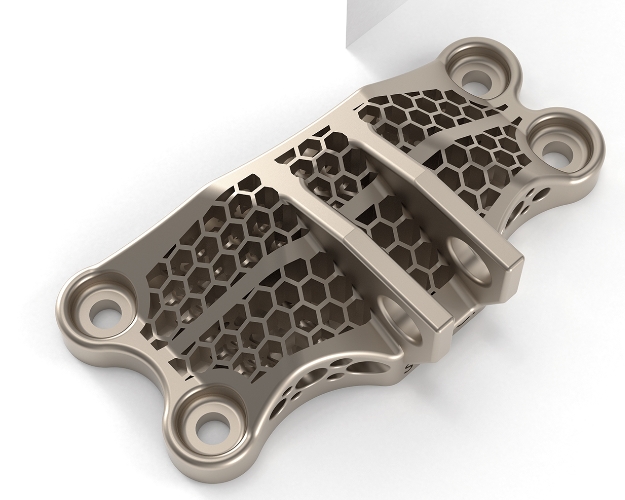

64 Ti(titanium)

Use of titanium material 3DP reduces weight to 1/3

(1376 g → 427 g)

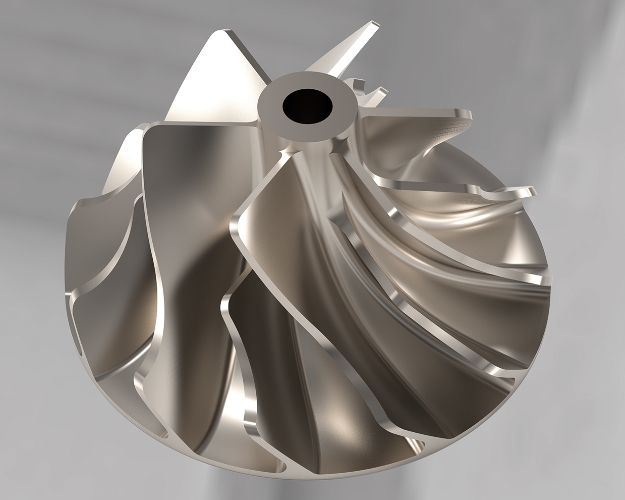

Inconel® 718

Shortens the time of near net shaping when switching

from machining by 5-axis cutting to 3DP molding

CoCr

Locking plate for tibial plateau fracture

CoCr, which is excellent in protecting against metal fatigue, cracking and loading, has been found to be useful in the medical field

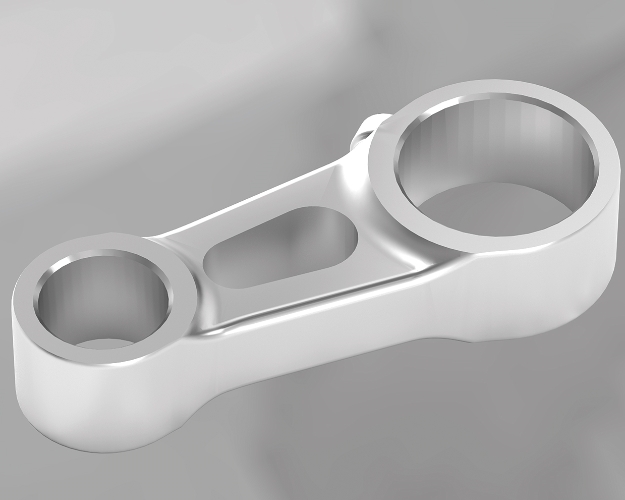

AlSi10Mg

Examples of molded parts that connect suspension of vehicles

Integration of connected parts

Freedom in design contributes to light weight