Factory VisitSodick America

Interview with Koji Yoneda CEO [2]

What is the "M4LINK" NC unit that melds technologies accumulated over time with leading-edge technologies?

It is a NC unit that has been redeveloped to combine a motion controller, isn't it?

Mr. Toyonaga, Center Director, has been a colleague since Sodick America was launched. (See his interview afterwards)

Sodick has been manufacturing NC units based on the technologies accumulated in the company over 10 or 20 years. The amount of software is also enormous, but we thought it should all be reviewed for the sake of the future. Sodick America developed the latest "M4LINK" NC unit by referring to these software assets that we accumulated over many years and making a comprehensive review of them to clarify anything we were unclear about. This allows us to explain everything to any new developer who comes along.

What is the great appeal of "M4LINK" ?

It is so easily customizable. For instance, with previous products, we had to handle the customization of the movements of X and Y axes, say, for example, in working parts of a machine each time. Now, that isn't necessary with this "M4LINK". First of all, we created the basic "M4LINK" software.

The Development Department in Japan then wrote programs to run on it. Customization is then easily performed by running the appropriate program on the M4LINK software. This enhances both the ease-of-use and development efficiency of the machine as a whole.

How long does it take before the software is loaded in a product?

For example, "M4LINK" was first installed in a machining center. This took about one year, with to-and-fro between us and the Development Department in Japan. As for a wire-cut EDM, it was displayed at the JIMTOF show in Japan three years ago and we are working to further increase the speed, efficiency, and functionality of it.

Some machine models containing "M4LINK" allow a tablet-type screen, don't they? Performance was quite adequate, so why did you set this new challenge?

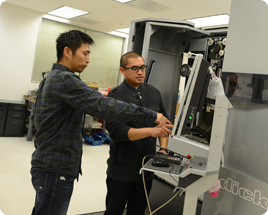

Koji Yoneda CEO and Mark the software manager is checking the tablet operation

That’s a very good question. Indeed, rather than worrying what a machine looks like, we in the machine tool world place more emphasis on whether the machine moves accurately and doesn't stop due to bugs. Both manufacturers and users alike tend to be conservative. On the other hand, software and hardware technologies are improving rapidly in all fields. So, we can't stand still. We wanted to make machines which can survive for another 10 years at the very least, so we worked to create the new "M4LINK".

What are the actual advantages to the customer of a tablet-type screen?

Using a tablet-type model allows the screen to be switched between the conventional “classic mode” and the “tablet mode.” The tablet mode was created to permit intuitive operations and aims to be usable without referring to the manual. It eliminates the keyboard that was conventionally attached to machines, which offers benefits in terms of cost and assembly too.

Incidentally, the user interface displayed on the screen was also developed by Sodick America.

(For more details see the interview with Mark Picasso, the software manager)

I am happy if our customers are happy.

It's a simple thing, but that makes my work worthwhile.

When do you feel that your job is worthwhile?

It's really when I hear that something we made is easy to use or is a great product. Developers like us can only deal with certain departments in the company on a daily basis.

It's really when I hear that something we made is easy to use or is a great product. Developers like us can only deal with certain departments in the company on a daily basis.

So, I am very happy when I sometimes hear a customer's opinion through the Sales Department. This gives a developer great encouragement to work. (Laughs)

When do you become aware that something you have developed is actually being used?

When I'm doing development work in this office, it is difficult to sense that at all. More than 3,000 people work for Sodick around the world, each with their own family. However, it is sometimes difficult for the American staff, in particular, to realize how their own skills are supporting so many lives since offices and factories are all over the world. As it is important for them to realize this, we let them accompany us as often as possible when we attend the "IMTS" show in the U.S., "JIMTOF" in Japan, or when we visit our factory in Thailand. Mark, who developed the "Sm-ART" software, has visited Japan on two occasions as well.